At its core, a high-frequency induction heater works by using a powerful, rapidly changing magnetic field to generate heat directly within a conductive material. This is achieved without any physical contact, flame, or external heating element touching the part. The process converts electrical energy into a magnetic field and then back into thermal energy inside the workpiece itself.

An induction heater is not a conventional heater; it is an electromagnetic tool. It uses the principles of electromagnetic induction and electrical resistance to turn the target material into its own source of heat, enabling incredibly fast, precise, and efficient heating.

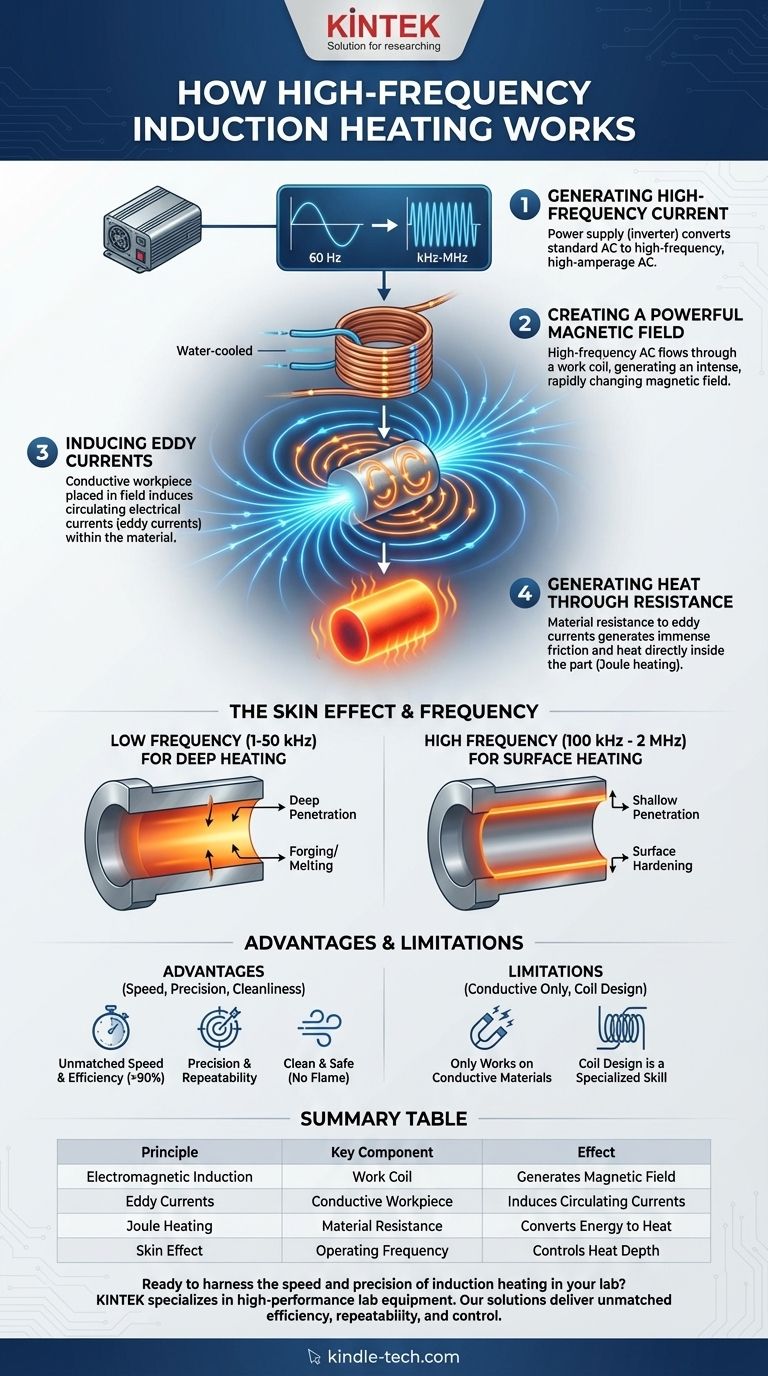

The Core Principle: A Four-Step Process

Induction heating is a direct result of two fundamental physics principles: Faraday's Law of Induction and the Joule heating effect. The entire process can be broken down into four distinct steps.

Step 1: Generating a High-Frequency Current

The system starts with a power supply, often called an inverter. This device takes standard AC line power (e.g., 60 Hz) and converts it into a high-frequency, high-amperage alternating current. Frequencies can range from a few kilohertz (kHz) for deep heating to several megahertz (MHz) for surface-level heating.

Step 2: Creating a Powerful Magnetic Field

This high-frequency AC is then sent through a work coil. This is typically a copper tube, often cooled with circulating water, that is formed into a specific shape. As the current alternates rapidly through this coil, it generates an intense and rapidly changing magnetic field in the space within and around the coil.

Step 3: Inducing Eddy Currents

When a conductive workpiece (like a piece of steel) is placed inside this magnetic field, the field induces circulating electrical currents within the material. These are known as eddy currents. They are the mirror image of the current flowing in the work coil.

Step 4: Generating Heat Through Resistance

The workpiece material has a natural resistance to the flow of these eddy currents. As the currents are forced to flow against this resistance, they generate immense friction at a molecular level, which is dissipated as heat. This phenomenon is known as Joule heating. Because the heat is generated inside the part, the process is extremely fast and efficient.

The Critical Role of Frequency: The Skin Effect

The choice of operating frequency is not arbitrary; it is the single most important parameter for controlling where the heat is generated.

What is the Skin Effect?

In AC circuits, current has a tendency to flow on the outer surface, or "skin," of a conductor. The higher the frequency of the alternating current, the more pronounced this skin effect becomes, and the shallower the depth of current penetration.

Low Frequency for Deep Heating

Lower frequencies (e.g., 1-50 kHz) penetrate deeper into the material. This is ideal for applications that require heating a large part all the way through, such as forging, forming, or melting large volumes of metal.

High Frequency for Surface Heating

Very high frequencies (e.g., 100 kHz - 2 MHz) cause the eddy currents to be concentrated in a very thin layer on the surface of the part. This is perfect for applications like surface hardening, where you want to create a hard, wear-resistant outer case while leaving the core of the part tough and ductile.

Understanding the Trade-offs and Advantages

Like any technology, induction heating has a distinct profile of strengths and weaknesses that make it ideal for some tasks and unsuitable for others.

Advantage: Unmatched Speed and Efficiency

Because heat is generated directly within the part, there is very little wasted energy. Heating cycles that take hours in a furnace can often be completed in seconds or minutes with induction, leading to energy efficiency ratings often exceeding 90%.

Advantage: Precision and Repeatability

The magnetic field can be precisely controlled by the shape of the work coil. This allows heat to be applied only where it is needed, protecting sensitive adjacent areas. Once a process is set, it is perfectly repeatable, ensuring consistent quality from part to part.

Advantage: Cleanliness and Safety

Induction is a clean process with no combustion byproducts, smoke, or toxic fumes. The absence of an open flame significantly improves workplace safety compared to traditional methods like flame torches or furnaces.

Limitation: Only Works on Conductive Materials

The primary limitation of induction heating is that it only works on materials that can conduct electricity, such as metals and graphite. It is ineffective for heating insulators like plastics, glass, or most ceramics, unless they are paired with a conductive "susceptor."

Limitation: Coil Design is a Specialized Skill

The efficiency and effectiveness of the entire system depend almost entirely on the work coil. Designing a coil that creates the correct heat pattern for a specific part geometry is a critical engineering task that often requires experience and iterative testing.

Making the Right Choice for Your Goal

The optimal setup depends entirely on the thermal process you need to accomplish.

- If your primary focus is surface hardening or case hardening: Use a very high frequency and high power density to rapidly heat the surface layer before quenching.

- If your primary focus is through-heating large billets for forging: Use a lower frequency and a multi-turn helical coil to ensure deep and uniform heat penetration.

- If your primary focus is brazing or soldering delicate joints: Use a moderate-to-high frequency with a precisely shaped coil to deliver localized heat only to the joint area.

- If your primary focus is melting metals in a crucible: Use a frequency optimized for the target metal's properties and a coil that couples efficiently with the conductive crucible.

By understanding these core principles, you can effectively leverage induction heating for unparalleled speed, precision, and control in your thermal processes.

Summary Table:

| Principle | Key Component | Effect |

|---|---|---|

| Electromagnetic Induction | Work Coil | Generates a rapidly alternating magnetic field |

| Eddy Currents | Conductive Workpiece | Induces circulating electrical currents inside the material |

| Joule Heating | Material Resistance | Converts electrical energy into heat directly within the part |

| Skin Effect | Operating Frequency | Controls the depth of heat penetration (surface vs. deep heating) |

Ready to harness the speed and precision of induction heating in your lab?

KINTEK specializes in high-performance lab equipment, including induction heating systems. Our solutions deliver unmatched efficiency, repeatability, and control for applications like brazing, hardening, and materials research.

Contact our experts today to discuss how we can provide the right induction heating equipment to enhance your laboratory's capabilities and accelerate your thermal processes.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance