At its core, a vacuum tube furnace is a high-temperature oven that heats a sample inside a sealed tube. It operates by surrounding the tube with external heating elements while a powerful vacuum system removes the air from inside the tube, creating an ultra-pure environment for material processing.

The fundamental purpose of a vacuum tube furnace is to achieve precise thermal processing while preventing the material from reacting with atmospheric gases like oxygen. It achieves this by physically isolating the sample within a sealed tube and chemically isolating it by creating a vacuum.

The Core Components and Their Roles

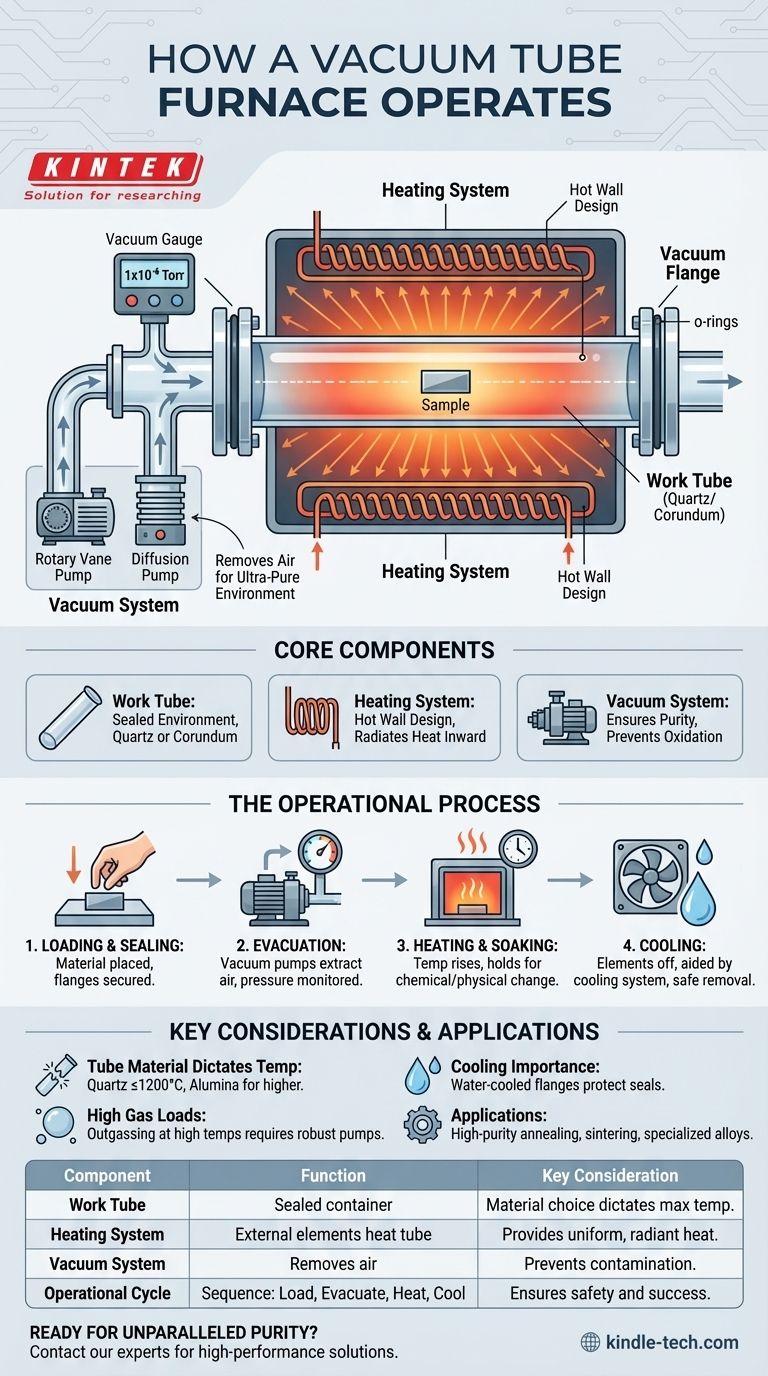

Understanding how a vacuum tube furnace operates begins with its three primary systems: the heating chamber, the work tube, and the vacuum system.

The Work Tube: The Sealed Environment

The sample is never directly exposed to the furnace's heating elements. Instead, it is placed inside a work tube, typically made of quartz or corundum (alumina).

This tube acts as the sealed container. Its ends are fitted with vacuum flanges that create an airtight seal, isolating the interior environment from the outside air.

The Heating System: External Heat Application

The furnace itself contains heating elements that surround the outside of the work tube. This is known as a "hot wall" furnace design.

When a user sets a temperature, the controller directs these external elements to heat up. This heat radiates inward, heating the walls of the work tube, which in turn heats the sample inside through radiation and convection.

The Vacuum System: Ensuring Purity

The vacuum system is what separates this from a standard tube furnace. It is connected to one of the flanges to actively pump out all the air and other gases from inside the work tube.

A typical system uses a rotary vane pump to achieve a preliminary vacuum, often backed by a high-speed diffusion pump to reach very deep vacuum levels (e.g., 1x10⁻⁶ Torr). A vacuum gauge monitors the pressure, ensuring the environment remains pure.

The Step-by-Step Operational Process

A typical operational cycle follows a precise sequence to ensure both safety and successful material processing.

Step 1: Loading and Sealing

First, the material to be processed is placed inside the work tube. The vacuum flanges are then secured to both ends of the tube, creating a complete seal.

Step 2: Evacuation (Pumping Down)

The vacuum system is activated. The pumps begin extracting air from the sealed tube, and the operator monitors the vacuum gauge until the desired pressure level is reached.

Step 3: Heating and Soaking

With the vacuum established, the user programs a temperature profile into the furnace controller. The heating elements energize, raising the temperature to the target setpoint.

The furnace then "soaks" or holds this temperature for a predetermined period to allow the desired chemical or physical change in the material to complete.

Step 4: Cooling

Once the heating cycle is finished, the heating elements are turned off. The furnace begins to cool down, often aided by a cooling system (like water-cooled flanges) to bring the sample safely back to room temperature before it is removed.

Understanding the Trade-offs and Key Considerations

While powerful, vacuum tube furnaces have operational principles that introduce important trade-offs.

Tube Material Dictates Temperature

The choice of work tube material is critical. Quartz tubes are common but typically limited to temperatures around 1100-1200°C. For higher temperatures, a more durable and expensive corundum (alumina) tube is required.

High Gas Loads at High Temperatures

As materials get very hot, they can "outgas," releasing trapped gases from their surface. A robust vacuum system with a high pumping speed is necessary to remove these gases and maintain the low-pressure environment during the heating cycle.

The Importance of Cooling

The extreme temperature difference between the hot center of the tube and the room-temperature ends creates significant thermal stress. Many systems require water cooling for the flanges to protect the o-ring seals from melting, which would cause a catastrophic vacuum leak.

Making the Right Choice for Your Application

Selecting and operating a vacuum tube furnace depends entirely on your material and processing goals.

- If your primary focus is high-purity annealing or sintering: A system with a high-performance diffusion pump capable of achieving a deep vacuum is essential to prevent any oxidation.

- If your primary focus is processing above 1200°C: Your setup must be based around a corundum (alumina) work tube, as quartz will fail at these temperatures.

- If your primary focus is creating specialized alloys or materials: The vacuum environment is non-negotiable, as it prevents atmospheric gases from contaminating the final product.

Ultimately, a vacuum tube furnace provides unparalleled control over the thermal and chemical environment for developing advanced materials.

Summary Table:

| Component | Function | Key Consideration |

|---|---|---|

| Work Tube | Sealed container for the sample (quartz or alumina) | Material choice dictates max temperature (e.g., quartz ≤1200°C) |

| Heating System | External elements heat the tube via 'hot wall' design | Provides uniform, radiant heat to the sample |

| Vacuum System | Removes air to create an ultra-pure environment | Prevents oxidation and contamination; manages outgassing |

| Operational Cycle | Sequence: Load, Evacuate, Heat/Soak, Cool | Ensures safety and successful material processing |

Ready to achieve unparalleled purity and precision in your material processing? KINTEK specializes in high-performance vacuum tube furnaces and lab equipment, providing the reliable, contamination-free environment your R&D or production needs. Contact our experts today to find the perfect solution for your high-temperature applications!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- What environmental conditions does a vacuum tube furnace provide for copper sintering? Ensure High-Purity Results

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance