At its core, debinding is a critical purification step in manufacturing that uses heat and a controlled atmosphere to remove a temporary "binder" from a molded or printed part. This is done inside a specialized furnace, where the binder is systematically broken down and vaporized, then carried away by a vacuum system or a flow of inert gas. This leaves behind a fragile part made of only the final material, ready for its final strengthening process.

The fundamental goal of debinding is to remove the sacrificial binder that gives a part its initial shape without distorting, cracking, or contaminating the final component. This is achieved by carefully controlling temperature and atmosphere to either evaporate the binder or chemically break it down into components that can be safely extracted.

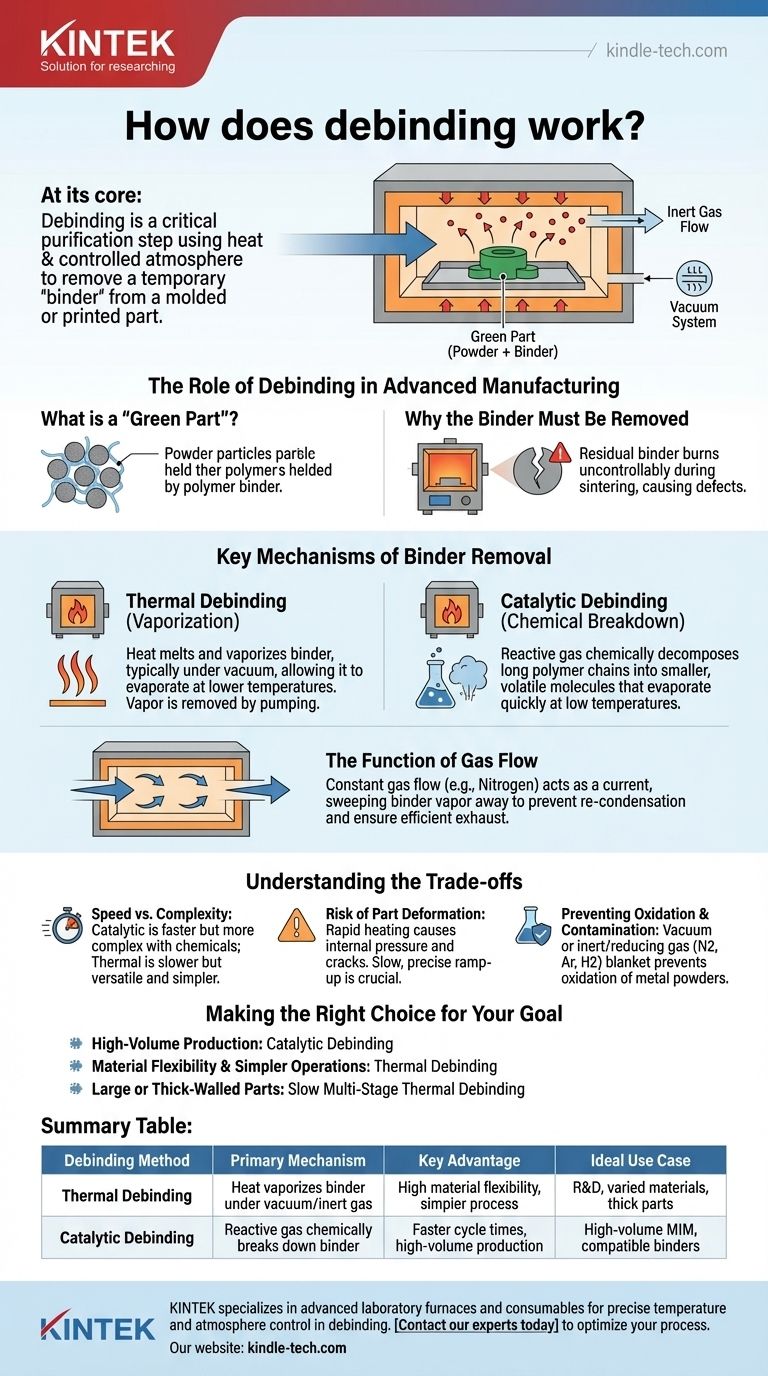

The Role of Debinding in Advanced Manufacturing

Before a metal or ceramic part achieves its final density and strength, it begins as a "green part." This green part is a mixture of the final material powder (like steel) and a sacrificial binder (often a polymer).

What is a "Green Part"?

A green part is the initial output of processes like Metal Injection Molding (MIM) or binder jet 3D printing. The binder acts like a temporary glue, holding the metal or ceramic powder in the desired shape.

While the part has the correct geometry, it lacks the strength and density of the final product. The binder must be removed completely before the next stage.

Why the Binder Must Be Removed

The final step in creating a dense part is sintering, where the part is heated to just below its melting point. The material particles fuse, and the part shrinks and densifies.

If the binder were still present during sintering, it would burn off uncontrollably, releasing gases that create voids, cracks, and impurities. Debinding ensures a clean, pure structure for successful sintering.

Key Mechanisms of Binder Removal

Debinding isn't a single process but a category of techniques. The two primary methods are thermal and catalytic, both of which rely on transforming the solid binder into a gas for removal.

Thermal Debinding (Vaporization)

In thermal debinding, heat is the primary tool. By raising the temperature in a controlled manner, typically under a vacuum, the binder is heated until it melts and then vaporizes (evaporates).

The vacuum environment is crucial as it lowers the boiling point of the binder, allowing it to turn into a gas at lower temperatures, which reduces stress on the part. This binder vapor is then removed by the furnace's vacuum pumping system.

Catalytic Debinding (Chemical Breakdown)

This method uses a reactive gas to chemically decompose the binder. The part is heated in a furnace filled with a specific gas that acts as a catalyst.

This gas triggers a chemical reaction that breaks the long polymer chains of the binder into smaller, more volatile molecules. These smaller molecules evaporate quickly at a low temperature and are carried away.

The Function of Gas Flow

In both processes, a constant flow of gas is often maintained through the furnace. This gas, typically inert like nitrogen, acts like a current.

It sweeps the binder vapor away from the part, preventing it from re-condensing in cooler areas and ensuring it is efficiently exhausted from the chamber.

Understanding the Trade-offs

Choosing a debinding strategy involves balancing speed, cost, and the risk of part failure. The process is a delicate operation where precision is paramount.

Speed vs. Process Complexity

Catalytic debinding is significantly faster than thermal debinding, making it ideal for high-volume production. However, it requires specific, compatible binders and often involves hazardous chemicals, adding complexity.

Thermal debinding is slower but more versatile, as it can be adapted to a wider variety of binder materials and is generally a simpler process to manage.

Risk of Part Deformation

If heat is applied too quickly, the binder can vaporize rapidly inside the part. This creates internal gas pressure that can lead to swelling, distortion, or even cracks.

Therefore, debinding profiles must be ramped up slowly and precisely, especially for parts with thick cross-sections, to allow the binder to escape without causing damage.

Preventing Oxidation and Contamination

At debinding temperatures, metal powders are highly susceptible to oxidation if exposed to oxygen. Oxidation introduces impurities that weaken the final sintered part.

To prevent this, the process is performed in a vacuum or is purged with an inert gas (like nitrogen or argon) to create a protective blanket. In some cases, a reducing gas (like hydrogen) is used to actively reverse any minor oxidation that may occur.

Making the Right Choice for Your Goal

Your debinding strategy should align directly with your production goals and the specific characteristics of your parts.

- If your primary focus is high-volume production: Catalytic debinding is often the superior choice for its speed, provided you can manage the chemical and material-specific requirements.

- If your primary focus is material flexibility and simpler operations: Thermal debinding is a more adaptable and forgiving method suitable for a wide range of applications, including research and development.

- If you are working with large or thick-walled parts: A slow, multi-stage thermal debinding cycle is critical to safely remove the binder without building up internal pressure that causes defects.

Mastering the debinding process is essential for transforming a fragile green part into a flawless, high-performance component.

Summary Table:

| Debinding Method | Primary Mechanism | Key Advantage | Ideal Use Case |

|---|---|---|---|

| Thermal Debinding | Heat vaporizes binder under vacuum/inert gas | High material flexibility, simpler process | R&D, varied materials, thick parts |

| Catalytic Debinding | Reactive gas chemically breaks down binder | Faster cycle times, high-volume production | High-volume MIM, compatible binders |

Ready to optimize your debinding process for flawless sintered parts?

KINTEK specializes in advanced laboratory furnaces and consumables for thermal processing. Our solutions provide the precise temperature and atmosphere control critical for successful debinding, helping you prevent defects and achieve superior part density.

Contact our experts today to discuss how our equipment can enhance your Metal Injection Molding (MIM) or additive manufacturing workflow.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas

- What are the typical heating zone configurations and maximum temperature capabilities of tube furnaces? Find the Right Setup for Your Lab

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process

- What are the disadvantages of rotary kiln incinerator? High Costs and Operational Complexities