At its core, heat treatment is a controlled process of heating and cooling a material to intentionally alter its internal structure. This manipulation is not superficial; it changes fundamental physical and mechanical properties, allowing engineers to enhance a material's strength, relieve internal stresses from manufacturing, improve wear resistance, or reduce brittleness to suit a specific application.

The fundamental purpose of heat treatment is to precisely manipulate a material's internal crystalline structure, altering its properties throughout the entire component, not just on the surface. It is the tool that turns a generic metal into a component engineered for a specific, demanding task.

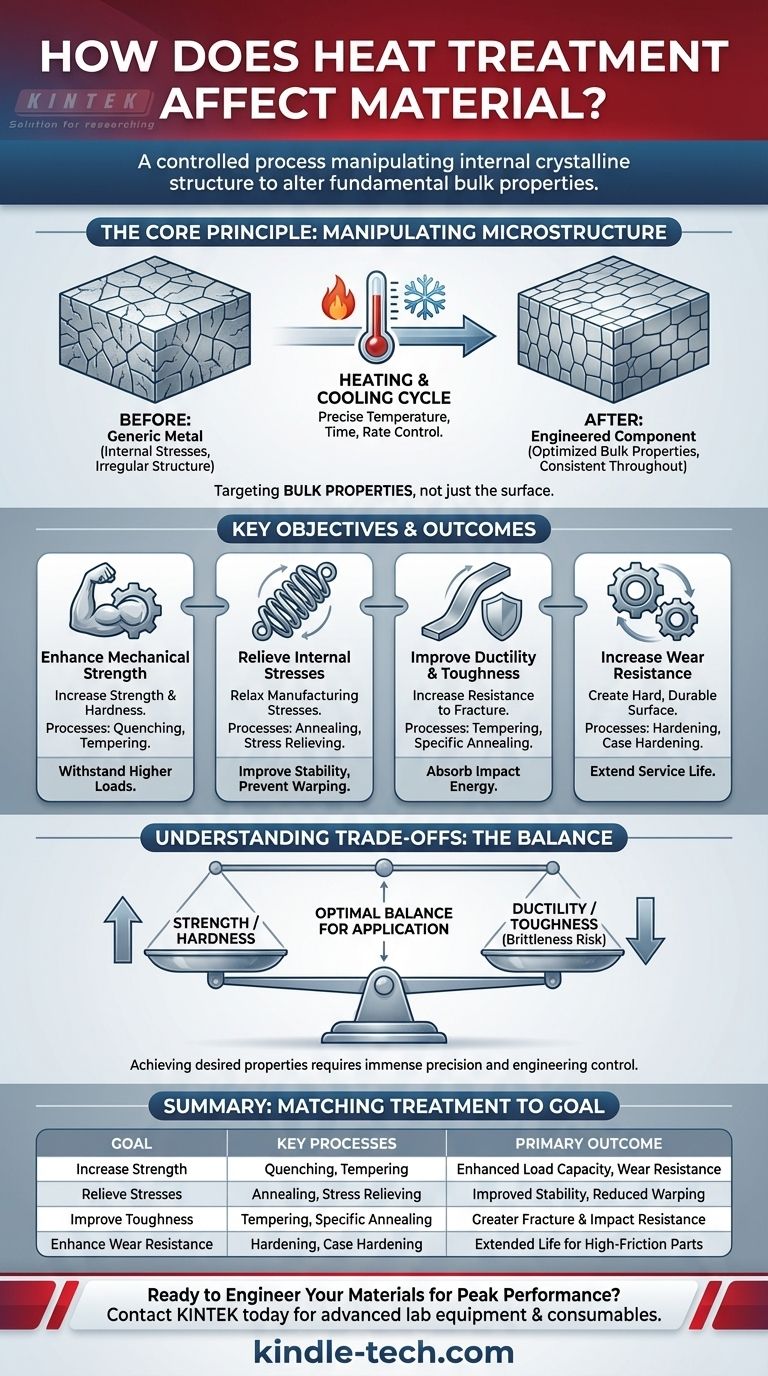

The Core Principle: Manipulating Microstructure

Heat treatment is a foundational process in materials science and manufacturing, particularly for metals like steel. Its effectiveness comes from the precise control it offers over a material's most basic characteristics.

Beyond Simple Heating and Cooling

This is not a crude process of just making a material hot. Heat treatment involves carefully managed cycles of heating to specific temperatures, holding for a set duration, and cooling at a controlled rate. Each phase of this cycle influences the final atomic arrangement, or microstructure, of the material.

Targeting Bulk Properties

The defining characteristic of heat treatment is that it modifies the bulk properties of a material. The changes occur deep within the component, ensuring that properties like strength and ductility are consistent throughout. This stands in contrast to surface-only modifications, such as plasma treatment, which change the chemistry of the surface without altering the core material beneath.

Key Objectives of Heat Treatment

Engineers use heat treatment to achieve several distinct, and often competing, performance goals. The chosen process depends entirely on the desired outcome for the final part.

Enhancing Mechanical Strength

One of the most common goals is to increase a material's strength and hardness. This allows components to withstand higher loads and resist deformation. Processes like quenching and tempering are used to create a harder, stronger microstructure, which is critical for tools, gears, and structural components.

Relieving Internal Stresses

Manufacturing processes like welding, machining, or hot forming can introduce significant internal stresses into a material. These stresses can lead to warping or cracking over time. A heat treatment process known as annealing or stress relieving heats the material and allows it to cool slowly, which relaxes these stresses and makes the part more stable and easier to machine.

Improving Ductility and Toughness

While strength is important, so is the ability to resist fracture. Heat treatment can be used to improve ductility (the ability to deform without breaking) and toughness (the ability to absorb energy from an impact). This is crucial for parts that may experience sudden loads or shocks.

Increasing Wear Resistance

For components subjected to friction and abrasion, heat treatment can create a very hard, wear-resistant surface. This dramatically extends the service life of parts like bearings and cutting tools by making them more resistant to being worn away.

Understanding the Trade-offs

Selecting a heat treatment process is an exercise in balancing competing properties. Improving one characteristic often comes at the expense of another.

The Strength vs. Brittleness Compromise

Increasing a material's hardness and strength almost always reduces its ductility, making it more brittle. An extremely hard part may shatter under a sudden impact. The art of heat treatment lies in finding the optimal balance for the application, achieving the necessary strength without creating an unacceptable risk of fracture.

Process Complexity and Control

Achieving the desired properties requires immense precision. Incorrect temperatures, holding times, or cooling rates can completely ruin a component, making it too soft, too brittle, or dimensionally unstable. This is not a simple step but a highly controlled engineering process.

Distinguishing Bulk vs. Surface Modification

It is critical to understand if the goal requires changing the entire component or just its surface. If you need a part with an extremely hard, wear-resistant surface but a tough, ductile core, a bulk heat treatment may not be the ideal solution. In that case, surface-specific processes might be more appropriate.

Matching the Treatment to Your Goal

The right approach depends entirely on the problem you are trying to solve. Use these points as a guide to determine your needs.

- If your primary focus is maximizing load-bearing capacity: Your goal is to increase strength and hardness, often through processes like quenching and tempering.

- If your primary focus is improving stability after welding: You need to relieve internal stresses, making annealing the most appropriate choice.

- If your primary focus is preventing fracture from impact: You need to optimize for toughness and ductility, which requires a careful balance of heating and cooling cycles.

- If your primary focus is extending the life of a high-friction part: You need to maximize surface hardness to improve wear resistance.

Ultimately, heat treatment transforms a standard material into a high-performance component engineered for a specific task.

Summary Table:

| Goal | Key Heat Treatment Processes | Primary Outcome |

|---|---|---|

| Increase Strength/Hardness | Quenching, Tempering | Enhanced load-bearing capacity, wear resistance |

| Relieve Internal Stresses | Annealing, Stress Relieving | Improved dimensional stability, reduced warping |

| Improve Toughness/Ductility | Tempering, Specific Annealing | Greater resistance to fracture and impact |

| Enhance Wear Resistance | Hardening, Case Hardening | Extended service life for high-friction components |

Ready to Engineer Your Materials for Peak Performance?

Achieving the perfect balance of strength, toughness, and durability requires precise control. KINTEK specializes in the advanced lab equipment and consumables necessary for developing and validating your heat treatment processes. Our solutions help you accurately manipulate material properties for superior results.

Contact our experts today to discuss how we can support your specific laboratory and material science challenges.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan