At its core, vacuum freeze drying removes water by first freezing the material solid and then creating a powerful vacuum. This low-pressure environment forces the frozen water (ice) to turn directly into a gas in a process called sublimation. By completely skipping the liquid phase, the method preserves the material's original structure, flavor, and nutritional value.

The fundamental principle of freeze drying isn't just about removing water; it's about preserving the original material. By skipping the liquid water phase, the process avoids the cellular damage and shrinkage that typically occur during conventional heat-based drying.

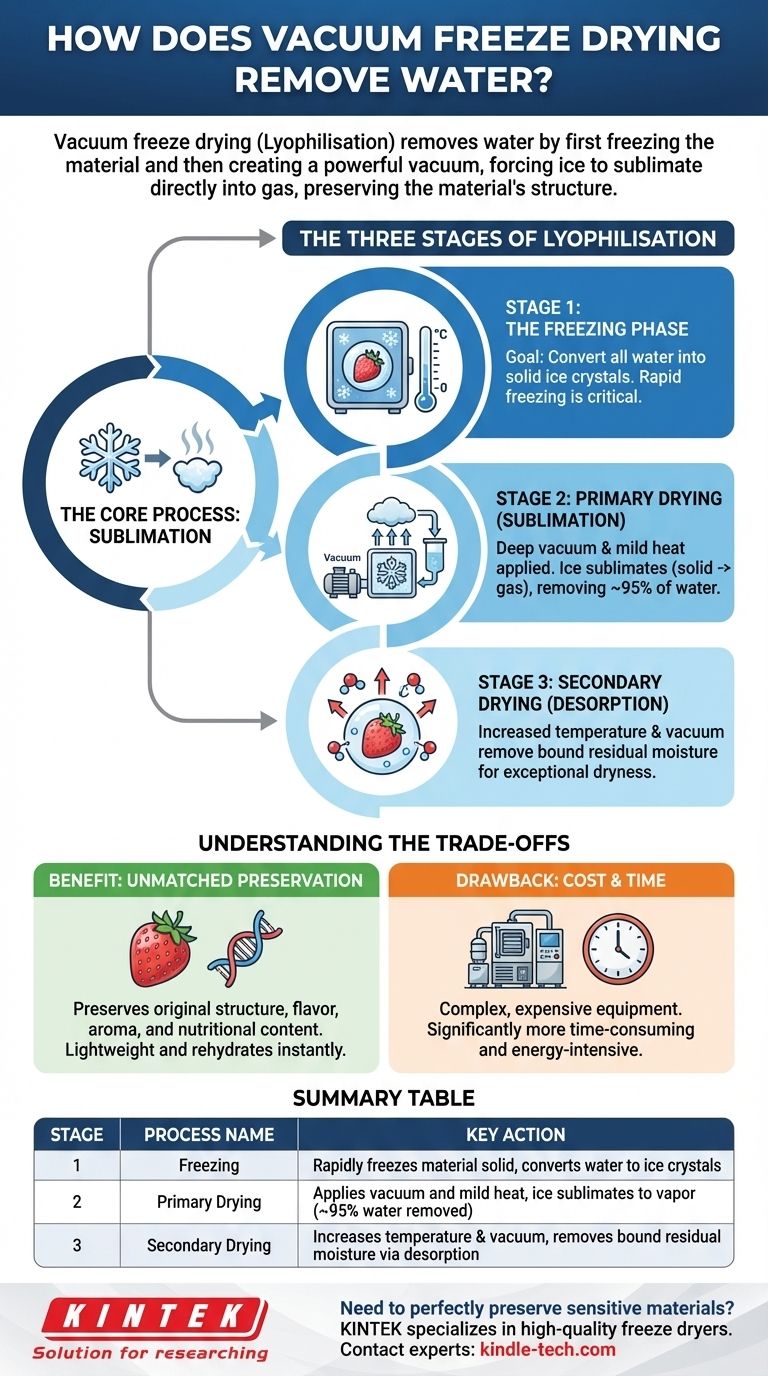

The Three Stages of Lyophilisation

Freeze drying, also known by its scientific name lyophilisation, is a highly controlled, three-part process. Each stage serves a distinct purpose in removing water while protecting the integrity of the material.

Stage 1: The Freezing Phase

The first step is to completely freeze the material. This is done rapidly and at temperatures well below the freezing point of water.

The goal is to convert all the water within the material into solid ice crystals. The careful control of this freezing process is critical for the success of the subsequent stages.

Stage 2: Primary Drying (Sublimation)

This is the heart of the freeze-drying process. Once frozen, the material is placed under a deep vacuum, dramatically lowering the pressure around it.

At this low pressure, a small amount of heat is applied. This gives the ice crystals just enough energy to sublimate—transforming directly from solid ice into water vapor gas.

The vacuum pump continuously removes this water vapor from the chamber. This stage removes the vast majority of the water, typically around 95%.

Stage 3: Secondary Drying (Desorption)

Even after sublimation, a small amount of water molecules remains chemically bound to the material's surface.

To remove this residual moisture, the temperature is raised slightly and the vacuum is often increased even further. This breaks the bonds holding the water molecules, a process called desorption, and ensures the final product is exceptionally dry and shelf-stable.

Understanding the Trade-offs

While incredibly effective, freeze drying is a specialized process with clear benefits and drawbacks compared to simpler methods.

The Benefit: Unmatched Preservation

By avoiding liquid water, which can damage cell walls and dissolve sensitive compounds, freeze drying is unparalleled in its ability to preserve a material's original characteristics.

The final product retains its shape, color, aroma, and nutritional content. It is also extremely lightweight and can be rehydrated almost instantly.

The Drawback: Cost and Time

The equipment required for freeze drying is complex and expensive. The process itself is also significantly more time-consuming and energy-intensive than conventional dehydration methods that use heat and airflow.

Making the Right Choice for Your Goal

Understanding the core mechanism helps you decide when this method is appropriate.

- If your primary focus is preservation quality: Freeze drying is the gold standard for maintaining the structural and nutritional integrity of sensitive materials like pharmaceuticals, biological samples, or high-end food.

- If your primary focus is speed and cost-efficiency: Conventional dehydration (oven or air drying) is a much faster and cheaper method for removing water when preserving the original structure is less critical.

Ultimately, choosing freeze drying is a decision to prioritize the perfect preservation of the material over the efficiency of the process.

Summary Table:

| Stage | Process Name | Key Action | Result |

|---|---|---|---|

| 1 | Freezing | Rapidly freezes material solid | Converts all water into ice crystals |

| 2 | Primary Drying | Applies vacuum and mild heat | Ice sublimates directly into vapor (removes ~95% water) |

| 3 | Secondary Drying | Increases temperature and vacuum | Removes bound residual moisture via desorption |

Need to perfectly preserve sensitive materials?

KINTEK specializes in high-quality lab equipment, including freeze dryers designed for pharmaceuticals, biological samples, and premium food products. Our solutions ensure unmatched preservation of structure and nutritional content.

Contact our experts today to find the ideal freeze-drying system for your laboratory's specific needs!

Visual Guide

Related Products

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What does hot-pressing do? Transform Materials with High-Temperature, High-Pressure Densification

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity

- What are hot presses used for? Transforming Materials with Heat and Pressure

- How do automated precision furnaces influence Zr1Nb structural evolution? Master Hydrogenation and Polygonization

- How does temperature affect vacuum pressure? Master the Key to System Control