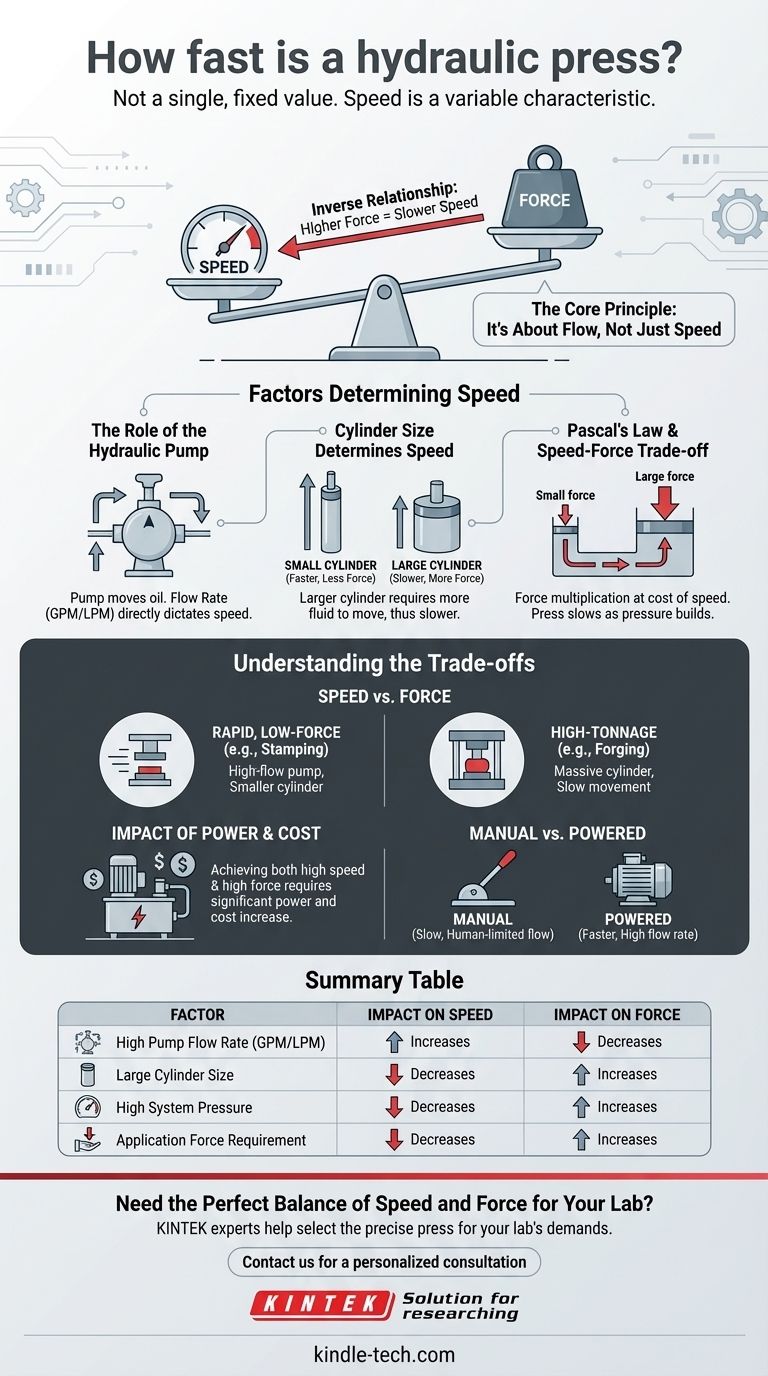

The speed of a hydraulic press is not a single, fixed value. Unlike a mechanical press that operates at a set number of strokes per minute, a hydraulic press's speed is a variable characteristic determined by the flow rate of its hydraulic pump and the force required for the operation. The core principle is an inverse relationship: the higher the force, the slower the press will move for a given power source.

The essential takeaway is that a hydraulic press's speed is governed by hydraulic fluid flow, not mechanical gearing. This means you can have high speed at low force, or high force at low speed, but achieving both simultaneously requires a significant increase in the system's power and cost.

The Core Principle: It's About Flow, Not Just Speed

To understand the speed of a hydraulic press, you must look beyond simple velocity and focus on the movement of hydraulic fluid within the system.

The Role of the Hydraulic Pump

The heart of the system is the hydraulic pump. Its job is to move a specific volume of oil over time, a specification known as the flow rate, measured in gallons per minute (GPM) or liters per minute (LPM). This flow rate directly dictates how fast the press cylinder can extend or retract.

How Cylinder Size Determines Speed

The pump's flow fills the press cylinder, causing the piston to move. A cylinder with a larger diameter requires more fluid to move the same distance. Therefore, for the same pump, a larger cylinder (which can generate more force) will inherently move more slowly than a smaller one.

Pascal's Law and the Speed-Force Trade-off

A hydraulic press operates on Pascal's Law, which allows it to multiply force. Pressure applied to the fluid is transmitted equally throughout the system. This principle is what allows a small force on a small piston to generate a massive force on a larger piston.

However, this force multiplication comes at the cost of speed. To achieve high pressure and force, the flow rate from the pump often decreases, slowing the cylinder's movement. The press moves fastest when it requires little force and slows down as it meets resistance and pressure builds.

Understanding the Trade-offs

The design and operation of a hydraulic press are a constant balance of competing factors. Understanding these trade-offs is crucial for selecting the right equipment.

The Central Conflict: Speed vs. Force

This is the primary trade-off. A press configured for rapid, low-force movements (like stamping thin material) will use a high-flow pump and a smaller cylinder. A press designed for high-tonnage applications (like forging) will have a massive cylinder that moves very slowly as it builds immense pressure.

The Impact of Power and Cost

You can overcome the speed-force trade-off, but only by investing in more power. A press that is both very fast and very powerful requires a large, expensive hydraulic power unit (the motor and pump) capable of moving a high volume of fluid even at extreme pressures.

Manual vs. Powered Presses

A manual hydraulic press, operated by a hand lever, is the clearest example of this principle. Its speed is limited entirely by the operator's physical ability to pump the fluid. Because a human cannot generate the high flow rate of a motorized pump, these presses are effective for generating force but are inherently very slow.

Making the Right Choice for Your Application

Instead of asking "how fast is the press," the more effective question is "what speed and force combination does my application require?"

- If your primary focus is high-tonnage force: Be prepared for slower cycle times, as the machine's primary function is to build pressure, not to move quickly.

- If your primary focus is rapid cycle times: Prioritize a system with a high-flow pump and understand that this may limit the maximum achievable force or significantly increase the unit's cost.

- If you need both speed and force: Seek a modern, two-stage press. These systems use a high-flow, low-pressure stage for a rapid approach and then automatically shift to a low-flow, high-pressure stage for the actual pressing work.

Ultimately, understanding that press speed is a direct function of hydraulic flow empowers you to select a machine based on its true performance capability for your specific task.

Summary Table:

| Factor | Impact on Speed | Impact on Force |

|---|---|---|

| High Pump Flow Rate (GPM/LPM) | Increases | Decreases (for a given power) |

| Large Cylinder Size | Decreases | Increases |

| High System Pressure | Decreases | Increases |

| Application Force Requirement | Decreases (as resistance increases) | Increases (to meet the requirement) |

Need the Perfect Balance of Speed and Force for Your Lab?

The right hydraulic press is critical for efficient sample preparation, molding, or material testing. KINTEK specializes in lab equipment and consumables, and our experts can help you select a press that delivers the precise speed and tonnage your application demands.

Contact our team today for a personalized consultation to ensure your lab is equipped for optimal performance and productivity.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of a vacuum hot pressing furnace? Achieve Superior Lithium Niobate Piezoelectric Density

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- What function does the vacuum environment serve during the densification of Ag-SnO2-Y2O3? Optimize Material Density

- Why is vacuum sintering equipment essential for hot pressing sub-micron metal powders? Ensure Purity and Conductivity