In the biological sciences, freeze drying is the definitive method for removing water from sensitive materials to ensure their long-term stability and preserve their biological activity. It is used extensively for preserving everything from vaccines and antibodies to bacteria, tissues, and blood plasma. The process, known as lyophilization, works by freezing the material and then using a high-pressure vacuum to turn the ice directly into vapor, completely bypassing the damaging liquid water phase.

The core value of freeze drying isn't merely dehydration; it's the preservation of a biological material's intricate structure and function. By converting solid ice directly into a gas—a process called sublimation—it avoids the destructive forces that liquid water exerts on delicate molecules, ensuring the sample remains viable for future use.

The Core Principle: Bypassing the Liquid Phase

What is Lyophilization?

Lyophilization is a low-temperature dehydration process that involves freezing a product, lowering the pressure, and then removing the ice by sublimation. The ultimate goal is to create a stable, easily storable product.

Because the process removes water at low temperatures, it minimizes damage to the product's chemical structure. This is critical for biological materials where the shape and integrity of molecules like proteins and enzymes are directly tied to their function.

The Science of Sublimation

The entire technique hinges on the principle of sublimation. This is the physical process where a substance transitions directly from a solid to a gas state, without ever becoming a liquid.

By freezing the water in a biological sample and then placing it under a deep vacuum, the frozen water molecules gain enough energy to escape directly as vapor. This vapor is then collected on a cold condenser surface inside the freeze dryer, effectively removing it from the sample.

The Three-Phase Process of Freeze Drying

Lyophilization is a carefully controlled process broken down into three distinct stages to ensure the sample's integrity is maintained.

Phase 1: Freezing

First, the biological material is rapidly frozen. This is a critical step, as the way the ice crystals form can impact the final structure of the dried product. The goal is to bring the material well below its freezing point to ensure all water is converted to a solid state.

Phase 2: Primary Drying (Sublimation)

Once frozen, the product is placed under a deep vacuum. A small amount of heat is then carefully applied, providing the energy needed for the frozen water to sublimate directly into water vapor. This phase removes the bulk of the water from the product.

Phase 3: Secondary Drying (Adsorption)

After the free ice has been sublimated, some water molecules remain bound to the material. The temperature is gradually raised (while still under vacuum) to break these bonds and remove the residual moisture. This final step is crucial for ensuring long-term stability.

Key Applications in Biological Fields

The ability to preserve activity and structure makes freeze drying indispensable across numerous biological and pharmaceutical disciplines.

Pharmaceuticals and Vaccines

Freeze drying is essential for stabilizing vaccines, antibodies, and antibiotics. Many of these products are unstable in liquid form and would quickly lose their effectiveness. Lyophilization allows them to be stored for extended periods and transported without requiring a constant cold chain.

Research and Diagnostics

In the laboratory, freeze drying is used to preserve bacteria, viruses, proteins, enzymes, and other cultures. This allows researchers to create stable stocks of materials for experiments and diagnostic tests. It is also used to prepare pathological samples and tissues for analysis.

Other Biological Materials

The technique is also applied to a wide range of other sensitive materials. This includes creating stable forms of blood plasma, preserving delicate plant extracts, and stabilizing venom for antivenom production.

Understanding the Trade-offs

While highly effective, freeze drying is not a universal solution. It involves specific considerations and limitations.

Equipment and Energy

Freeze dryers are complex, specialized machines that are expensive to purchase and operate. The process of pulling a deep vacuum and maintaining very low temperatures is highly energy-intensive.

Process Time

Lyophilization is a slow, methodical process. A single cycle can take anywhere from several hours to several days to complete, depending on the material and the amount of water to be removed. This makes it less suitable for high-throughput applications where speed is the primary concern.

Process Optimization

There is no single freeze-drying recipe. Each biological material has unique properties, and the freezing rate, vacuum level, and temperature profile must be carefully optimized to prevent damage and ensure a successful outcome. An incorrect protocol can ruin the sample.

Making the Right Choice for Your Goal

Deciding to use freeze drying depends entirely on the need to preserve the biological function and structural integrity of your material.

- If your primary focus is long-term stability and transport: Freeze drying is the gold standard for creating products that can be stored at ambient temperatures without losing their biological activity.

- If your primary focus is preserving delicate molecular structures: The sublimation process is unmatched in its ability to remove water without denaturing proteins or damaging cellular components.

- If your primary focus is easy and accurate reconstitution: Lyophilized products are designed to rehydrate quickly and completely, returning to a state that is functionally almost identical to the original material.

Ultimately, freeze drying is chosen when the value and sensitivity of the biological material justify a process dedicated to its ultimate preservation.

Summary Table:

| Application | Key Materials Preserved | Primary Benefit |

|---|---|---|

| Pharmaceuticals | Vaccines, Antibodies, Antibiotics | Stable storage & transport without cold chain |

| Research & Diagnostics | Bacteria, Viruses, Proteins, Enzymes | Creates stable stocks for experiments & tests |

| Other Biologicals | Blood Plasma, Plant Extracts, Venom | Maintains integrity and potency for future use |

Ready to achieve superior preservation for your sensitive biological materials? The right equipment is critical for successful lyophilization. KINTEK specializes in precision lab equipment and consumables, serving the exacting needs of laboratories in pharmaceuticals, biotech, and research. Let our experts help you select the ideal freeze-drying solution to protect your valuable samples and ensure their long-term viability. Contact our team today to discuss your specific application and requirements!

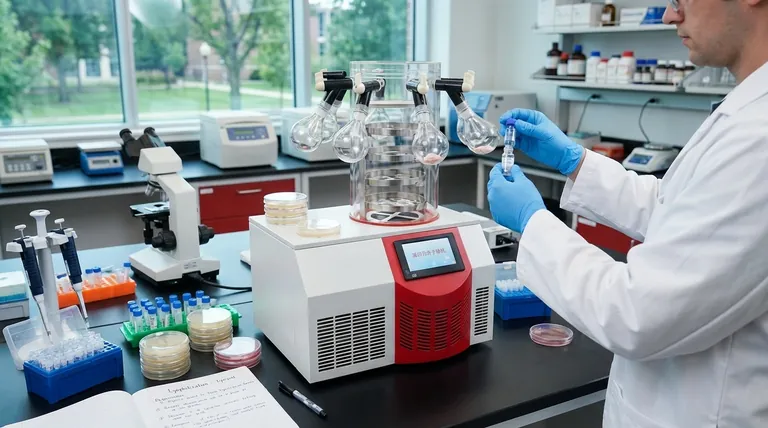

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is a lyophilizer and how does it work? Unlock Superior Preservation for High-Value Materials

- What are the disadvantages of using a Laboratory Freeze Dryer? High Costs, Long Times, and Technical Demands

- What problems should be avoided when using a lyophilizer? Prevent Product Collapse and Equipment Overload

- What benefits do laboratory freeze dryers provide in chemical and biotechnological processes? Preserve Purity & Stability

- What are the key reasons to use a freeze dryer in laboratories? Preserve Sample Integrity for Reliable Research