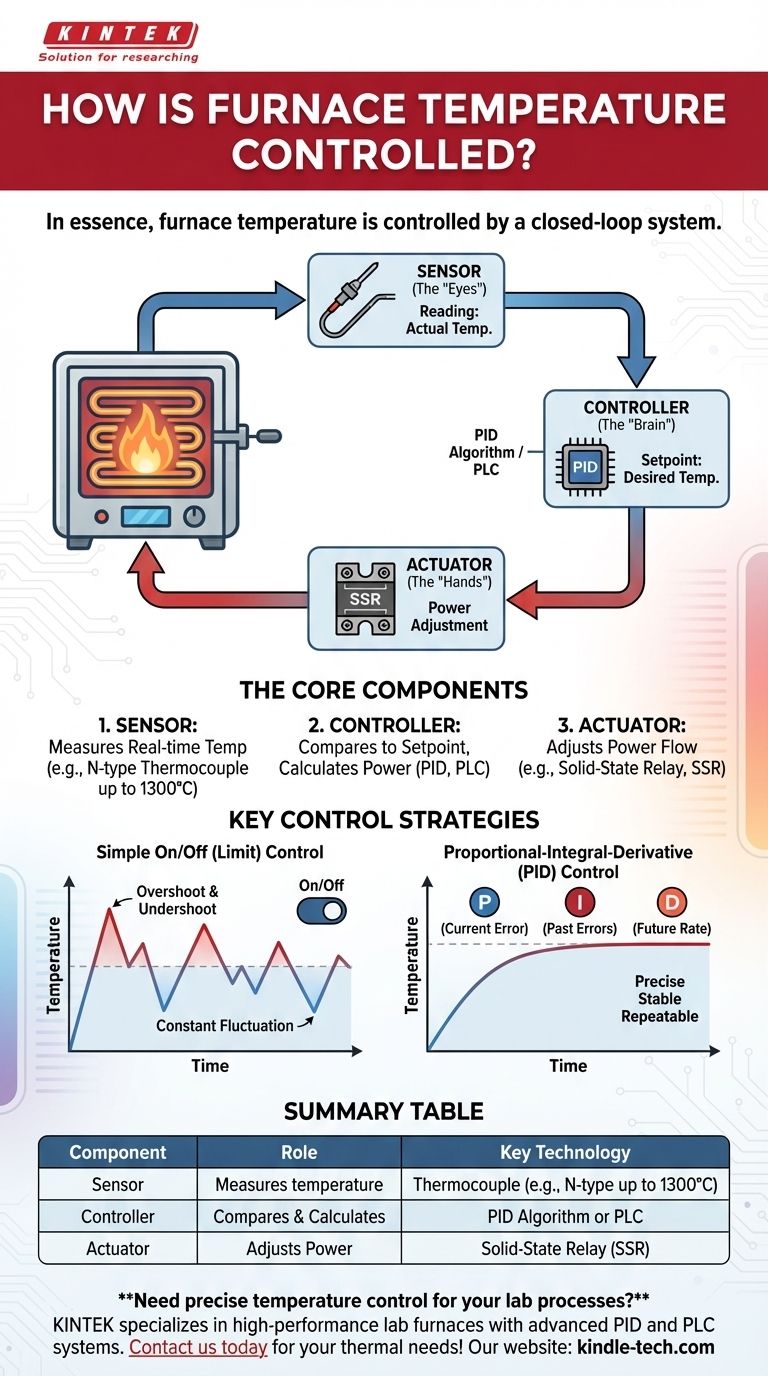

In essence, furnace temperature is controlled by a closed-loop system. This system continuously measures the internal temperature with a sensor, compares it to the desired temperature (the setpoint), and uses a controller to precisely adjust the power sent to the heating elements to minimize the difference.

The core principle is not just heating, but intelligent regulation. Modern furnaces rely on a constant cycle of measuring, comparing, and adjusting power—most often using a PID controller—to achieve stable and precise temperatures without constant manual intervention.

The Core Components of Temperature Control

A furnace's temperature control system is composed of three critical parts that work in a continuous loop: the sensor, the controller, and the actuator.

The Sensor (The "Eyes")

The sensor is responsible for accurately measuring the real-time temperature inside the furnace chamber.

The most common type is a thermocouple, such as the industry-standard N-type nickel-chromium-silicon, which is durable and reliable for high-temperature applications up to 1300°C.

The Controller (The "Brain")

The controller is the central processor. It takes the temperature reading from the thermocouple and compares it to the programmed setpoint.

Based on the difference, it calculates precisely how much power the heating elements need. This can range from a simple programmable unit to a fully automatic PLC (Programmable Logic Controller) integrated into a larger system.

The Actuator (The "Hands")

The actuator receives the command from the controller and physically adjusts the power flow to the heating elements.

In modern electric furnaces, this is typically a Solid-State Relay (SSR). An SSR can switch power on and off thousands of times per second, allowing for extremely fine-grained control over the heat output.

Key Control Strategies Explained

While the components are universal, the strategy the controller uses to make decisions can vary significantly in complexity and precision.

Simple On/Off (Limit) Control

This is the most basic method. If the temperature is below the setpoint, the controller sends 100% power. Once it's above the setpoint, it cuts power completely.

This method is simple but results in constant temperature overshooting and undershooting, making it unsuitable for processes requiring high stability.

Proportional-Integral-Derivative (PID) Control

PID control is the standard for nearly all modern precision furnaces, from laboratory models to industrial sintering units. It is a sophisticated algorithm that adjusts power based on three factors.

- Proportional (P): Reacts to the current error. The further the temperature is from the setpoint, the more power it applies.

- Integral (I): Reacts to the sum of past errors. This corrects for small, steady-state temperature drifts, ensuring the furnace eventually settles exactly at the setpoint.

- Derivative (D): Reacts to the rate of future error. It anticipates where the temperature is going, reducing power as it quickly approaches the setpoint to prevent overshooting.

Advanced and Automated Control

For highly complex processes, even more advanced strategies exist. Feedforward control can compensate for predictable disturbances, while fuzzy logic allows the system to handle imprecise variables.

These systems are often managed by a PLC, which can run entire heating, soaking, and cooling programs automatically with the press of a button.

Understanding the Trade-offs

Choosing and operating a furnace requires understanding the balance between precision, simplicity, and safety.

Precision vs. Simplicity

An on/off controller is simple and cheap but imprecise. A PID controller delivers exceptional stability and repeatability for sensitive processes like sintering, but it must be properly "tuned" to the specific furnace to perform optimally.

The Importance of System Monitoring

No control system is infallible. It is critical to monitor the furnace's operation during a cycle to watch for abnormalities. A perfectly programmed controller cannot prevent a hardware failure, such as a faulty thermocouple or a failing heating element.

Automation Comes with Responsibility

The ability to program a full heat treatment cycle and press "run" is a massive advantage in efficiency and repeatability. However, this automation relies on the operator setting the program correctly according to the furnace's instructions and process requirements.

Making the Right Choice for Your Process

Your specific goal determines which level of control is necessary for your work.

- If your primary focus is basic heating without high precision: A simple limit or on/off controller is sufficient and cost-effective.

- If your primary focus is stable, repeatable, and precise temperatures: A PID controller is the non-negotiable industry standard for tasks like heat treatment, sintering, or lab research.

- If your primary focus is integrating the furnace into a complex, automated workflow: A PLC-based control system provides the most power and flexibility for multi-step, unattended operation.

Understanding these control principles empowers you to operate your furnace not just as a heater, but as a precision instrument tailored to your exact needs.

Summary Table:

| Component | Role | Key Technology |

|---|---|---|

| Sensor | Measures temperature | Thermocouple (e.g., N-type up to 1300°C) |

| Controller | Compares & calculates | PID Algorithm or PLC |

| Actuator | Adjusts power | Solid-State Relay (SSR) |

Need precise temperature control for your lab processes? KINTEK specializes in high-performance lab furnaces with advanced PID controllers and PLC systems, ensuring stable and repeatable results for sintering, heat treatment, and research. Let our experts help you select the right furnace for your application. Contact us today to discuss your specific thermal processing needs!

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace Tubular RTP Heating Furnace

People Also Ask

- What is the temperature of a graphite furnace? Achieve Extreme Heat Up to 3000°C

- Why graphite is used in furnace? Achieve Superior Heat Treatment & Energy Efficiency

- What temperature can graphite withstand? Unlocking Its Extreme Heat Potential

- Can graphite withstand heat? Unlocking its extreme 3,600°C potential in inert environments

- What are the advantages of graphite furnace? Achieve High-Temperature Precision and Purity