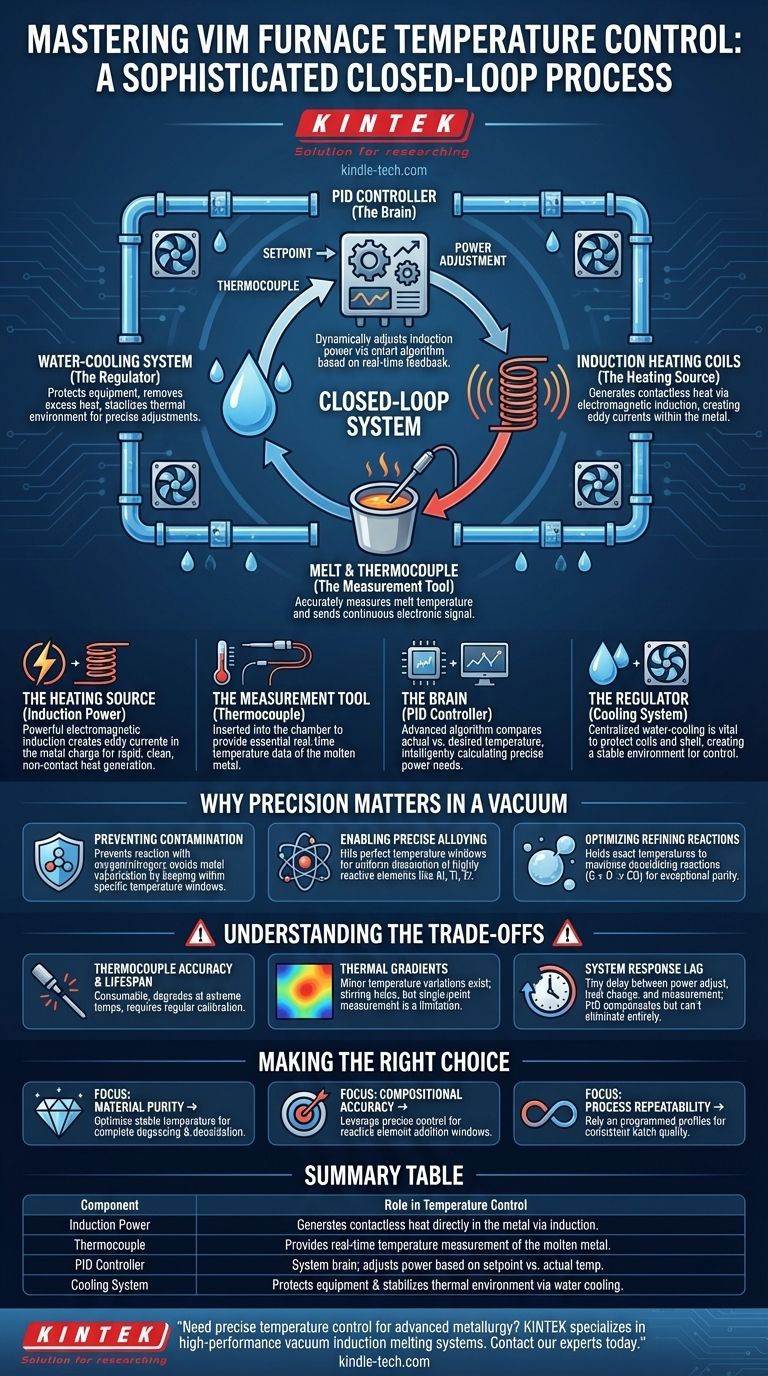

At its core, temperature control in a vacuum induction melting (VIM) furnace is a sophisticated, closed-loop process. It is managed by an electric control system that uses a PID controller to dynamically adjust the power sent to the induction heating coils, based on real-time feedback from a thermocouple measuring the melt temperature. This entire system is supported by a water-cooling circuit that protects the equipment and helps regulate the overall thermal environment.

The critical takeaway is that temperature control in a VIM furnace is not just about heating and cooling. It is a precision instrument designed to execute a specific thermal profile, enabling the advanced metallurgical refining and alloying that is only possible in a vacuum.

The Core Components of Temperature Control

A VIM furnace's temperature control system is an integration of four distinct but codependent parts, each with a critical role.

The Heating Source: Induction Power

The furnace generates heat without direct contact by using powerful electromagnetic induction. The electric control system sends high-frequency electrical currents through a copper coil.

This creates a powerful magnetic field that induces secondary electrical currents, known as eddy currents, directly within the metal charge. The metal's natural resistance to these currents generates intense, rapid, and clean heat.

The Measurement Tool: The Thermocouple

To control the temperature, the system must first measure it accurately. This is the job of a thermocouple.

A thermocouple is inserted into the furnace chamber and positioned to read the temperature of the molten metal. It sends a continuous electronic signal back to the control system, providing the essential real-time data needed for adjustments.

The Brain: The PID Controller

The heart of the control logic is the Proportional-Integral-Derivative (PID) controller. This is an advanced algorithm within the main electric control system that acts as the furnace's brain.

It constantly compares the actual temperature from the thermocouple to the desired temperature set by the operator (the "setpoint"). Based on this difference, it intelligently calculates the precise amount of power the induction coils need. It can be programmed with complex, multi-stage heating and cooling profiles to manage an entire melting process automatically.

The Regulator: The Cooling System

While it may seem counterintuitive, a centralized water-cooling system is vital for high-temperature control.

The induction coils and the furnace shell itself would quickly overheat and fail without active cooling. This system continuously circulates water to remove excess heat, protecting the equipment and creating a stable thermal environment where the PID controller can make precise adjustments to the melt itself.

Why This Precision Matters in a Vacuum

The need for such an advanced control system is driven by the unique metallurgical processes that occur within the vacuum environment.

Preventing Contamination

The entire process is conducted in a vacuum to prevent the molten metal from reacting with gases like oxygen and nitrogen. Precise temperature control ensures the metal stays hot enough for refining but doesn't become so hot that it begins to vaporize, which could alter the final composition.

Enabling Precise Alloying

VIM is used to create superalloys with very specific compositions. Many of these alloys include highly reactive elements like aluminum (Al), titanium (Ti), and zirconium (Zr).

Stable and accurate temperature control allows metallurgists to hit the perfect window for adding these elements, ensuring they dissolve uniformly into the melt without being burned off or forming unwanted compounds.

Optimizing Refining Reactions

Under vacuum, carbon becomes a powerful deoxidizer, reacting with oxygen in the melt to form carbon monoxide (CO) gas, which is then pumped out. This reaction is highly dependent on temperature.

The PID controller can hold the melt at the exact temperature needed to maximize this deoxidizing reaction, resulting in an exceptionally clean and pure final product.

Understanding the Trade-offs

While highly effective, the system is not without its operational realities and limitations.

Thermocouple Accuracy and Lifespan

Thermocouples are consumable items. At extreme temperatures and in contact with reactive molten metals, they can degrade over time, potentially leading to inaccurate readings. They require regular calibration and replacement.

Thermal Gradients

A thermocouple measures the temperature at a single point. The bulk of the molten metal, especially in large furnaces, can have minor temperature variations or gradients. The stirring action created by the induction field helps minimize this, but it is an inherent physical reality.

System Response Lag

There is a tiny but real delay between the PID controller adjusting the power, the heat of the melt changing, and the thermocouple registering that change. A well-tuned PID algorithm is designed specifically to anticipate and compensate for this lag, but it can never be eliminated entirely.

Making the Right Choice for Your Goal

The VIM furnace's temperature control system is a tool. How you use it depends entirely on your metallurgical objective.

- If your primary focus is material purity: Use the programmable controller to hold a stable temperature that optimizes the duration for degassing and deoxidation reactions to run to completion.

- If your primary focus is compositional accuracy: Leverage the precise control to create specific temperature windows for adding highly reactive alloying elements, ensuring they dissolve correctly without being lost.

- If your primary focus is process repeatability: Rely on the programmed heating and cooling stages to ensure that every melt cycle follows the exact same thermal profile, delivering consistent product quality from batch to batch.

Ultimately, mastering temperature control is fundamental to leveraging the full power of vacuum induction melting to produce the world's most advanced alloys.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| Induction Power | Generates contactless heat directly in the metal charge via electromagnetic induction. |

| Thermocouple | Provides real-time temperature measurement of the molten metal. |

| PID Controller | The system's brain; compares actual temperature to setpoint and adjusts power accordingly. |

| Cooling System | Protects equipment and stabilizes the thermal environment via water cooling. |

Need precise temperature control for your advanced metallurgy projects? KINTEK specializes in high-performance lab equipment, including vacuum induction melting systems. Our expertise ensures you achieve the material purity, compositional accuracy, and batch-to-batch repeatability required for producing superalloys. Contact our experts today to discuss your specific laboratory needs and how we can support your success.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the process of melting in an induction furnace? Harnessing Electromagnetic Power for Efficient Metal Melting

- How does magnetic field heat metal? Achieve Precise Thermal Control with Induction Heating

- What are the technical advantages of using an induction melting furnace? Precision for Nickel-Based Superalloys

- How does the induction furnace work? A Guide to Rapid, Clean Metal Melting

- What are the components of an induction melting furnace? A Guide to the Core Systems

- How does a vacuum induction furnace work? Master High-Purity Metal Melting

- What are the advantages of using coreless over core type induction furnace? Unmatched Flexibility for Diverse Alloys

- What is the induction furnace used for? Master Efficient Metal Melting & Heating