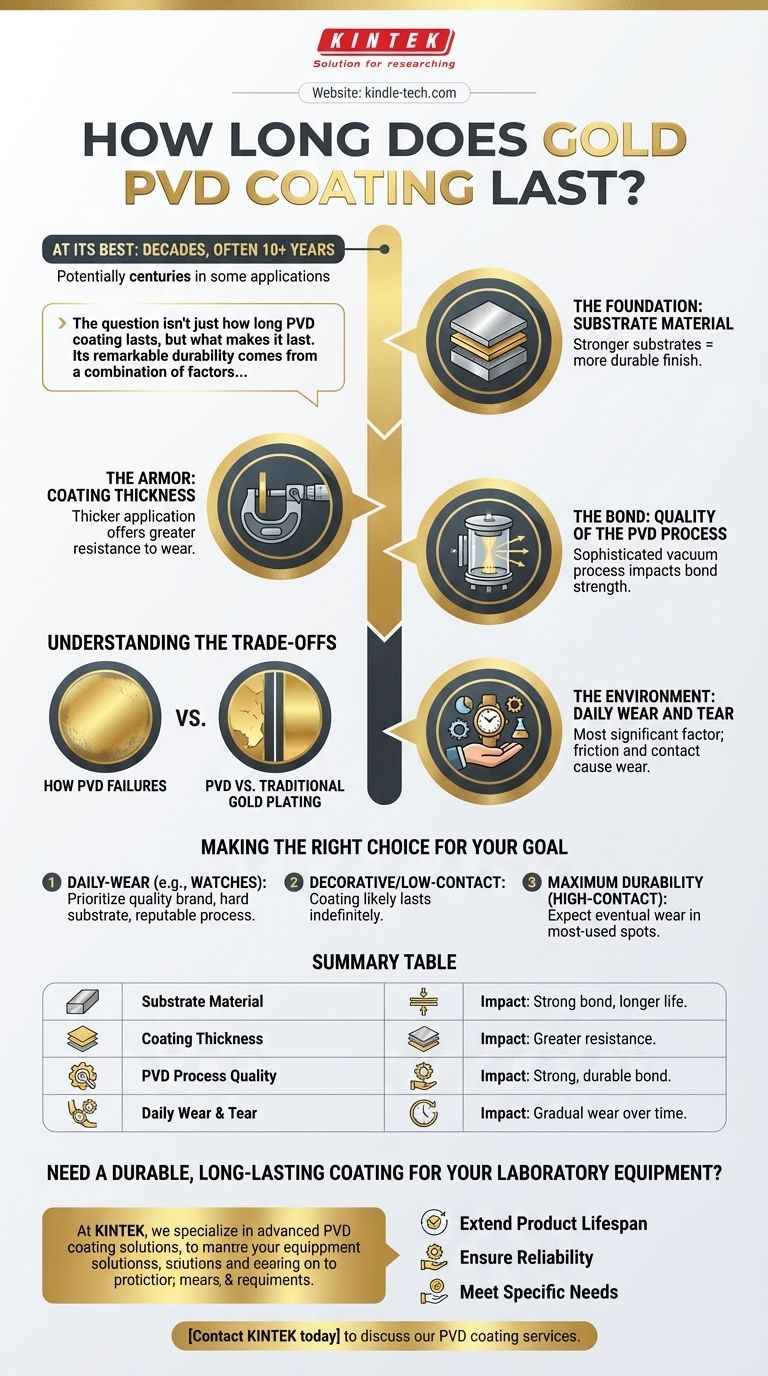

At its best, a high-quality gold PVD coating can last for decades, often exceeding 10 years and in some applications, potentially centuries. However, this lifespan is not a guarantee. It is highly dependent on the quality of the application, the thickness of the coating, the underlying material, and the wear it endures.

The question isn't just how long PVD coating lasts, but what makes it last. Its remarkable durability comes from a combination of factors, with daily use and the quality of the initial application being the most critical variables.

The Core Factors That Determine PVD Lifespan

The vast range in PVD's potential lifespan—from a decade to a lifetime—is determined by a few key variables. Understanding these will allow you to assess the quality of any PVD-coated product.

The Foundation: Substrate Material

The material underneath the PVD coating is called the substrate. The bond between the coating and the substrate is a primary factor in its longevity.

A strong, hard substrate like stainless steel or titanium provides a stable foundation for the PVD coating to adhere to, resulting in a more durable and long-lasting finish.

The Armor: Coating Thickness

Logically, a thicker coating provides more material to wear through over time. While PVD coatings are extremely thin (measured in microns), a thicker application will inherently offer greater resistance to abrasion and wear.

For items subject to daily contact and friction, such as watch bracelets or door handles, a thicker coating is essential for a long service life.

The Bond: Quality of the PVD Process

Physical Vapor Deposition (PVD) is a sophisticated process performed in a vacuum. The quality of this process directly impacts the strength of the bond between the coating and the substrate.

Improper surface preparation or suboptimal conditions during the coating process can create a weak bond, making the coating susceptible to premature failure, even with minimal wear.

The Environment: Daily Wear and Tear

This is the most significant factor in real-world longevity. A PVD-coated item that is handled frequently will have a different lifespan than one that is purely decorative.

Constant friction, exposure to heat, and contact with abrasive surfaces or chemicals will gradually wear down the coating over the years.

Understanding the Trade-offs

While PVD is a superior coating technology, it is not invincible. It's crucial to understand its limitations compared to other finishes.

How PVD Coatings Fail

High-quality PVD coatings do not typically chip or flake off. Instead, they fail through gradual abrasion. Over many years of use, the very top layers of the coating may slowly wear away in high-contact areas.

This wear is often graceful, unlike the peeling or flaking seen in lower-quality traditional plating.

PVD vs. Traditional Gold Plating

Gold PVD is significantly more durable than traditional gold plating. The PVD process creates a much harder, denser, and more corrosion-resistant surface.

Where gold plating might wear off in a few years with regular use, a well-applied PVD coating on a similar item can be expected to last for a decade or more.

Making the Right Choice for Your Goal

To determine if a PVD-coated product meets your needs, consider how you will use it.

- If your primary focus is a daily-wear item (like a watch or ring): Prioritize products from reputable brands that use hard substrates like stainless steel and have a history of quality PVD application.

- If your primary focus is a decorative or low-contact item: The PVD coating will likely last indefinitely, as it won't be subjected to the friction and wear that cause degradation.

- If your primary focus is maximum durability for a high-contact surface: Understand that while PVD is one of the most durable colored finishes available, it will eventually show signs of wear in the most-used spots.

Ultimately, choosing a product with a gold PVD finish is a choice for superior durability and long-term color fastness.

Summary Table:

| Factor | Impact on Lifespan |

|---|---|

| Substrate Material | Hard materials like stainless steel provide a stronger bond for longer life. |

| Coating Thickness | A thicker coating (in microns) offers greater resistance to abrasion and wear. |

| PVD Process Quality | A high-quality vacuum process ensures a strong, durable bond to the substrate. |

| Daily Wear & Tear | Frequent friction and contact with chemicals will gradually wear down the coating over time. |

Need a Durable, Long-Lasting Coating for Your Laboratory Equipment or Components?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory equipment and consumables. Our high-quality gold PVD coatings are engineered for maximum durability, corrosion resistance, and long-term performance—perfect for precision instruments, fixtures, and parts that face daily use.

We help you:

- Extend Product Lifespan: Protect your valuable equipment with a coating that lasts for decades.

- Ensure Reliability: Benefit from our expertise in creating strong, adherent coatings on various substrates.

- Meet Specific Needs: Get a tailored solution for your laboratory's unique requirements.

Contact KINTEK today to discuss how our PVD coating services can add value and longevity to your products.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How is diamond coating made? A Guide to CVD and PVD Methods

- How do you calculate coating coverage? A Practical Guide to Accurate Material Estimation

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies