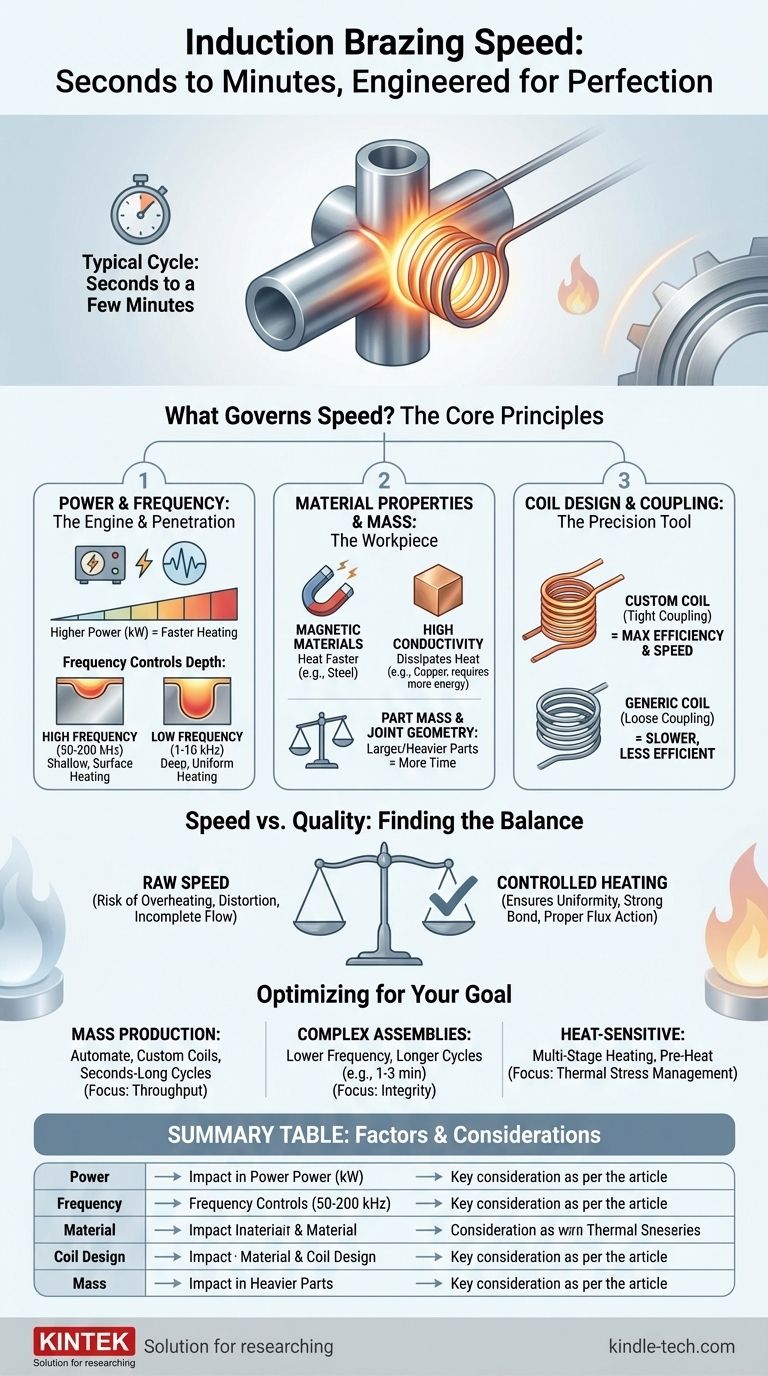

In practice, induction brazing is exceptionally fast. A typical induction brazing cycle is completed in a matter of seconds to a few minutes. This speed is one of the process's primary advantages, but the exact time is not a single number; it is a result of a carefully engineered system balancing the part's design, material properties, and the specifics of the heating equipment.

The time required for induction brazing is a direct function of part mass, material, joint design, and the power of the induction system. While often measured in seconds, the true goal is not maximum speed, but the fastest repeatable cycle that produces a perfect, high-integrity joint.

The Physics of Induction: What Governs Speed?

To understand brazing time, you must first understand the core principles of induction heating. The process uses an alternating magnetic field to induce electrical currents (eddy currents) within the metal parts. The resistance of the metal to these currents generates precise, localized heat.

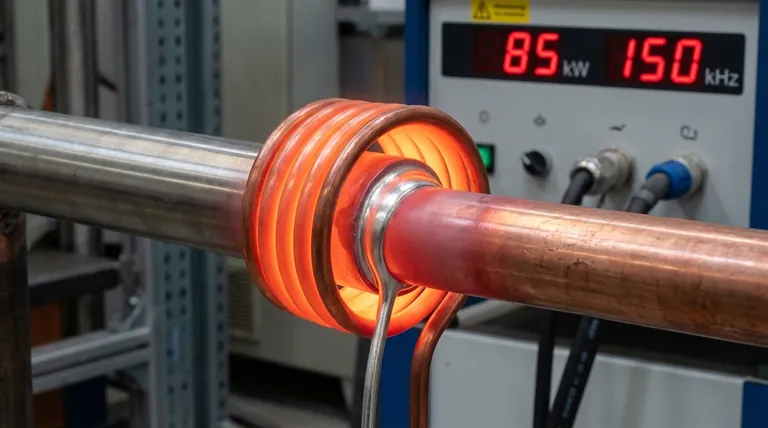

The Role of Power and Frequency

The power supply is the engine of the system. Higher power (measured in kilowatts, kW) allows for more energy to be delivered to the part, resulting in faster heating. Doubling the available power can often cut heating time in half.

Frequency is more nuanced. It controls the depth of heat penetration.

- High frequencies (e.g., 50-200 kHz) create a shallow heating effect, ideal for small parts, thin walls, or applications where you need to heat only the surface quickly.

- Low frequencies (e.g., 1-10 kHz) penetrate deeper into the material, which is necessary for heating large, thick, or massive parts uniformly to the core.

How Material Properties Influence Heating

Not all metals heat the same. Magnetic materials, like carbon steel, heat very efficiently below their Curie point (around 770°C or 1420°F) because of magnetic hysteresis losses, which adds a secondary heating effect.

Other key properties include electrical resistivity and thermal conductivity. Materials with higher electrical resistivity heat more effectively. Materials with high thermal conductivity, like copper, require a very high rate of energy input because they dissipate heat away from the joint area so quickly.

The Critical Importance of Coil Design

The induction coil is the "tool" that shapes the magnetic field and focuses the energy. Its design is arguably the single most important factor in determining efficiency and speed.

The distance between the coil and the workpiece, known as coupling, is critical. A tight coupling (closer distance) results in a much more efficient energy transfer and significantly faster heating. A custom-designed coil that perfectly matches the geometry of the joint is essential for optimal performance.

Part Mass and Joint Geometry

This is the most intuitive factor. A large, heavy part simply contains more mass that needs to be brought to temperature, requiring more energy and therefore more time.

The design of the braze joint itself also plays a role. The goal is to heat the entire joint area to a uniform temperature. A well-designed joint ensures that both parts reach the brazing temperature simultaneously, allowing the filler metal to flow quickly and evenly.

Understanding the Trade-offs: Speed vs. Quality

Simply applying maximum power to achieve the shortest time is a common mistake that leads to poor results. The goal is controlled, repeatable heating, not just raw speed.

The Risk of Overheating and Distortion

Heating a part too quickly creates severe thermal gradients, where the surface is much hotter than the core. This can lead to surface damage, grain growth in the metal, and part distortion or warping, especially in assemblies with dissimilar materials or complex shapes.

The Danger of Incomplete Filler Flow

A successful braze requires the entire joint to be at the correct temperature. If heat is applied too rapidly and non-uniformly, one area may become hot enough to melt the filler metal before the rest of the joint is ready. This causes the filler to flow incorrectly, creating voids and resulting in a weak, unreliable bond.

Ensuring Proper Flux and Filler Activity

If you are using a flux, it needs a specific amount of time at temperature to perform its cleaning action. Likewise, the brazing filler alloy needs a brief moment to flow via capillary action and completely wet the surfaces of the joint. Rushing this "soak time" can compromise the metallurgical bond.

Making the Right Choice for Your Goal

The ideal brazing time is a balance between production speed and joint quality. Your specific application dictates where you should focus your optimization efforts.

- If your primary focus is maximizing throughput for mass production: Invest in a highly automated system with custom-shaped coils and a precisely tuned power supply to achieve a repeatable, seconds-long heating cycle.

- If your primary focus is brazing large or complex assemblies: Prioritize uniform heating over raw speed. Use a lower frequency and a carefully designed coil, accepting a longer cycle time (e.g., 1-3 minutes) to ensure joint integrity and prevent distortion.

- If your primary focus is working with heat-sensitive or dissimilar materials: Implement a multi-stage heating profile, such as a lower-power pre-heat stage followed by a final ramp-up, to manage thermal stress and ensure a quality bond.

Ultimately, the optimal induction brazing time is not the fastest possible, but the fastest that reliably produces a strong, defect-free joint.

Summary Table:

| Factor | Impact on Brazing Time | Key Consideration |

|---|---|---|

| Power Supply (kW) | Higher power = faster heating | Match power to part mass and production goals |

| Frequency (kHz) | High frequency for small parts; low for large parts | Controls depth of heat penetration |

| Material Properties | Magnetic materials heat faster; high conductivity materials dissipate heat | Influences energy efficiency |

| Coil Design & Coupling | Custom coils and tight coupling drastically reduce time | Most critical factor for efficiency |

| Part Mass & Joint Geometry | Larger, heavier parts require more time | Goal is uniform heating of the entire joint area |

Ready to Optimize Your Brazing Process?

Whether your goal is high-volume production or joining complex, heat-sensitive assemblies, KINTEK's expertise in induction brazing systems can help you achieve the perfect balance of speed and quality. We specialize in providing the right lab equipment and consumables to meet your specific laboratory needs.

Contact us today to discuss how our solutions can deliver faster cycle times, repeatable results, and stronger, defect-free joints for your applications.

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Double Plate Heating Press Mold for Lab

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is a hydraulic hot press? Unlock the Power of Heat and Pressure for Advanced Materials

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More