The duration of the annealing process is not a single, fixed number. It is a highly variable engineering parameter that can range from a few hours to several days, depending on the specific metal, the thickness of the part, and the desired final properties. The total time is a sum of three distinct stages: heating, soaking, and controlled cooling.

The critical insight is that annealing time is primarily dictated by the material's thickness and composition. While general rules of thumb exist, the duration must be calculated to ensure the entire workpiece undergoes the necessary structural changes without introducing new defects.

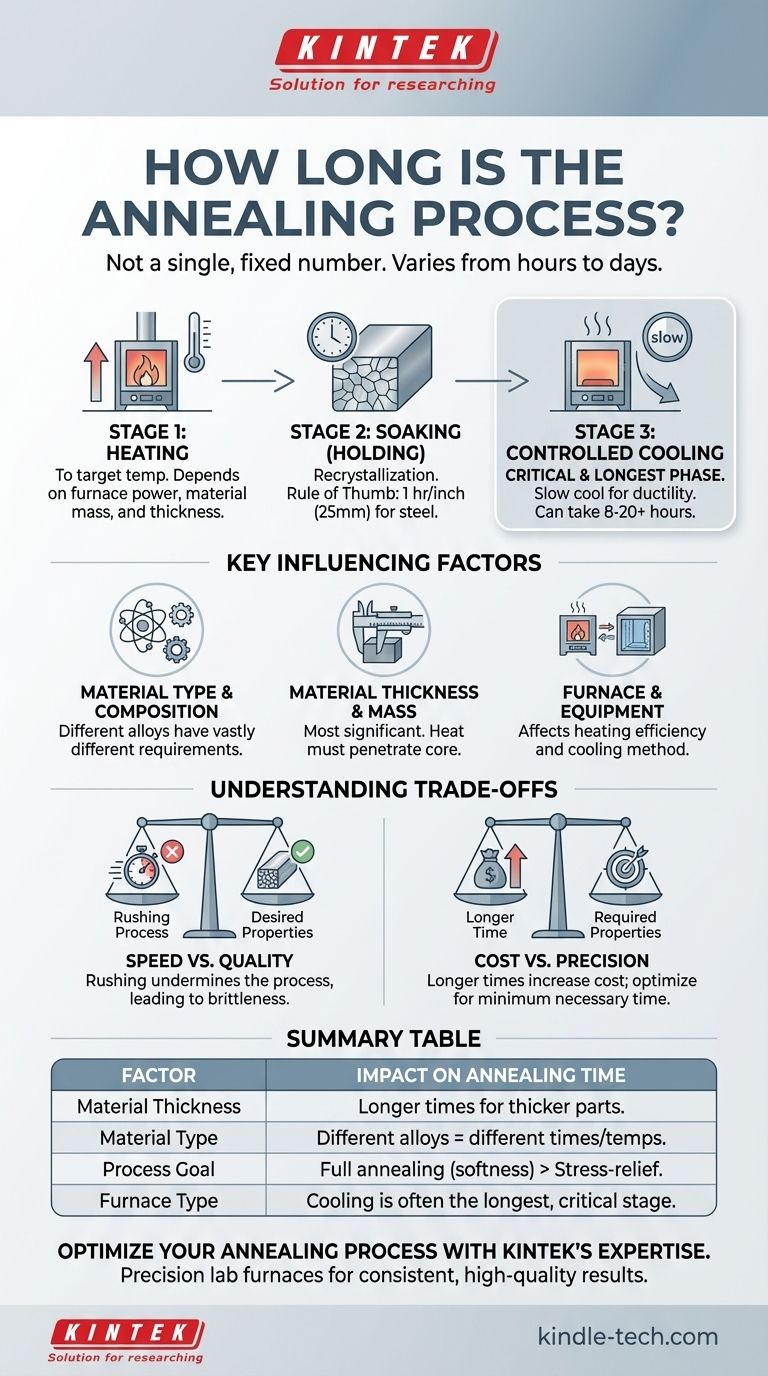

The Three Stages That Define Annealing Time

The total process time is the sum of its three core stages. The cooling stage is often the longest and most critical phase for achieving the desired outcome.

Stage 1: Heating to Temperature

The first stage involves heating the material to its specific annealing temperature. The time required depends directly on the furnace's power, the material's thermal conductivity, and the workpiece's overall mass and thickness.

A larger, thicker part will naturally take much longer to heat uniformly to its core than a small, thin one.

Stage 2: Soaking (Holding at Temperature)

Once the material reaches the target temperature, it is "soaked" or held there for a set period. This allows the material's internal crystalline structure to stabilize and repair defects through a process called recrystallization.

A common rule of thumb for steel is to soak for one hour for every inch (25mm) of thickness, but this is only a guideline. The exact time depends on the specific alloy and the initial state of the material.

Stage 3: Controlled Cooling

This is arguably the most critical stage for achieving the goals of annealing. The material must be cooled very slowly to allow a new, ductile, and stress-free grain structure to form.

Rushing this stage will undermine the entire process. Often, the most effective method is to simply turn the furnace off and allow the part to cool with the furnace, a process that can easily take 8-20 hours or more for large equipment.

Key Factors Influencing Total Duration

To properly estimate the time for an annealing process, you must consider the following variables. These factors work in combination to determine the final schedule.

Material Type and Composition

Different metals have vastly different annealing requirements. The annealing temperature for an aluminum alloy is far lower than for high-carbon steel, which directly impacts the heating and soaking time.

Furthermore, different alloying elements within a metal can significantly alter the time needed for the internal structure to transform.

Material Thickness and Mass

This is the most significant factor. Heat must penetrate the entire cross-section of the part. A thick component requires a longer heating period to ensure the core is at the same temperature as the surface.

Likewise, the soaking and cooling times are extended for thicker parts to ensure the entire mass undergoes a complete and uniform transformation.

Furnace and Equipment

The efficiency of the furnace plays a direct role. A high-power furnace can reduce the heating time, but the soaking and cooling rates are dictated by metallurgical principles, not equipment power.

The method of cooling—such as leaving the part in the insulated furnace versus moving it to a cooling chamber—will dramatically change the duration of the final stage.

Understanding the Trade-offs

Optimizing the annealing process requires balancing time and cost against the required material properties. Errors here can be costly and ineffective.

Rushing the Process vs. Desired Properties

The primary trade-off is speed versus quality. Attempting to shorten the cycle by cooling the material too quickly will negate the benefits of annealing. This can introduce new internal stresses and result in a brittle, rather than ductile, final product.

Cost vs. Precision

Longer furnace times directly translate to higher energy consumption and operational costs. The goal is to determine the minimum time necessary to achieve the desired metallurgical properties. Over-soaking can sometimes lead to excessive grain growth, which can be detrimental for certain applications.

Making the Right Choice for Your Goal

To determine the appropriate annealing time, you must first define your primary objective.

- If your primary focus is maximum softness and ductility: You must commit to a full annealing cycle with a very slow, controlled cooling stage, which is typically the longest option.

- If your primary focus is simply relieving internal stress: A shorter, lower-temperature process known as stress-relief annealing may be sufficient and save considerable time.

- If your primary focus is process planning for a specific alloy: Always consult the material's technical datasheet or a qualified metallurgist, as generalized rules are not sufficient for critical applications.

Ultimately, the duration of annealing is a precise calculation tailored to the material and the engineering goal.

Summary Table:

| Factor | Impact on Annealing Time |

|---|---|

| Material Thickness | Longer times for thicker parts (e.g., 1 hour/inch for steel soaking). |

| Material Type | Different alloys (e.g., aluminum vs. steel) require different temperatures and times. |

| Process Goal | Full annealing (softness) takes longer than stress-relief annealing. |

| Furnace Type | Affects heating rate, but cooling is often the longest, most critical stage. |

Optimize your annealing process with KINTEK's expertise.

The right annealing time is critical for achieving the desired material properties of softness, ductility, and stress relief. Getting it wrong can lead to costly rework or part failure.

KINTEK specializes in precision lab furnaces and consumables, providing the reliable equipment and technical support you need to execute perfect thermal cycles. Whether you're working with complex alloys or standard steels, our solutions help you achieve consistent, high-quality results.

Contact us today to discuss your specific application and ensure your annealing process is both efficient and effective.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance