It's a common point of confusion, but asking how many PSI is in a hydraulic press's force is like asking how many gallons are in a mile. PSI (pounds per square inch) is a unit of pressure, while the output of a press is measured as force (typically in pounds or tons). They are fundamentally different, but directly related, measurements.

The core principle to understand is that a press's output force is the result of its internal hydraulic pressure (in PSI) acting over the area of its piston. You cannot determine one without knowing the other.

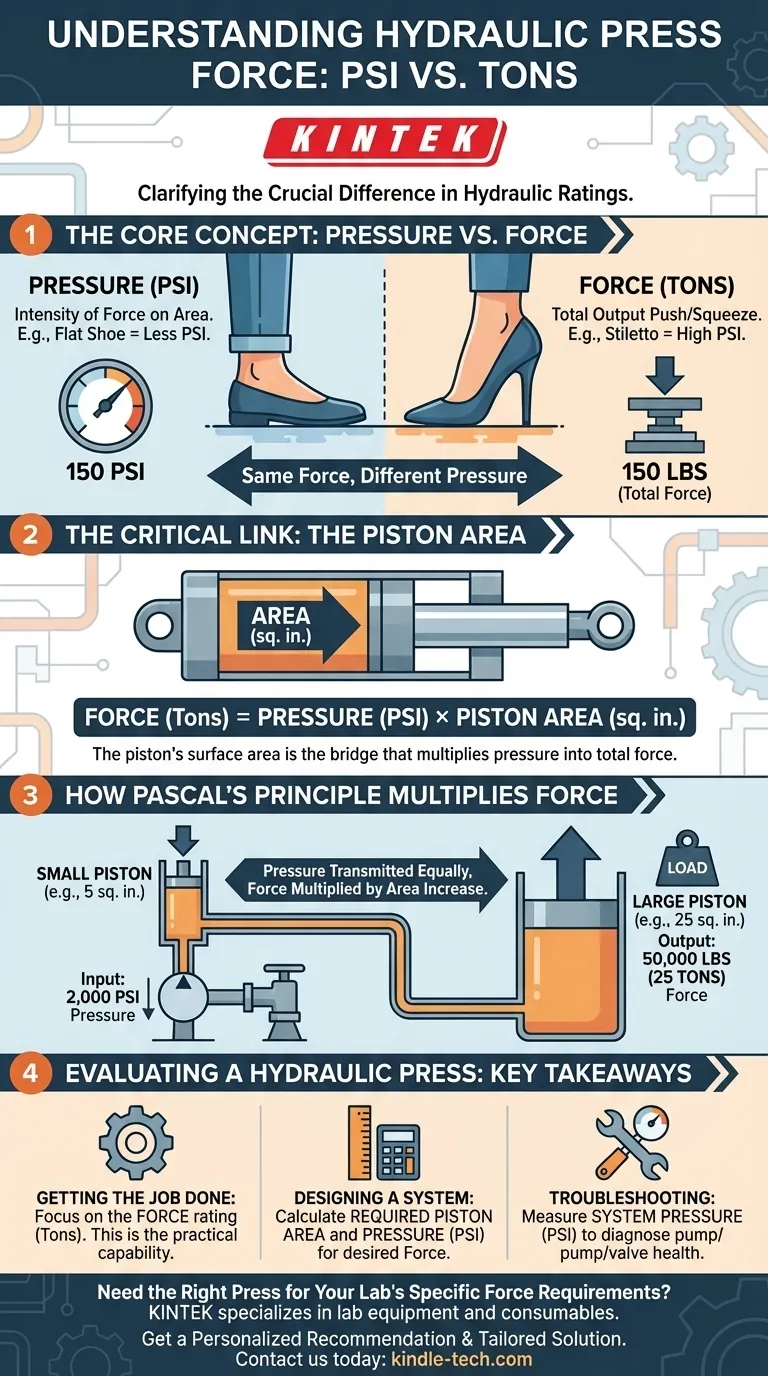

The Core Concepts: Pressure vs. Force

To understand how a hydraulic press works, we must first be precise about the terms we use. The power of hydraulics comes from the specific relationship between pressure, force, and area.

What is Pressure (PSI)?

PSI stands for "Pounds per Square Inch." It measures the intensity of a force distributed over a specific area.

Think of it like this: A 150-pound person standing on your foot with a flat shoe is uncomfortable. That same 150-pound person stepping on your foot with a stiletto heel causes immense pain. The force (150 pounds) is the same, but the pressure (PSI) is dramatically higher with the heel because the entire force is concentrated on a tiny area.

In a hydraulic press, the pump creates pressure in the fluid, which is the "intensity" ready to do work.

What is Force (Tons)?

Force is the total output push or squeeze that the press can exert. This is the specification that matters most for getting a job done and is usually advertised in tons (1 ton = 2,000 pounds).

When you see a "20-ton press," it means the machine can deliver a total of 40,000 pounds of force. This is the number that tells you the machine's true capability.

The Critical Link: The Piston

The bridge between internal pressure (PSI) and external force (tons) is the area of the hydraulic piston.

The fundamental formula is: Force = Pressure × Area.

A hydraulic system's fluid, at a certain PSI, pushes against the face of a piston. The larger the surface area of that piston, the more total force it can generate from the same amount of pressure.

How Pascal's Principle Creates Force Multiplication

Hydraulic systems create massive force from a relatively small input by leveraging a key law of physics.

Pascal's Principle Explained Simply

This principle states that pressure applied to a confined fluid is transmitted equally throughout the entire fluid.

In a press, this means the PSI created by the pump is felt equally everywhere inside the system, including against the large piston that does the work.

The Magic of Different Piston Sizes

This is where force multiplication happens. A pump might use a small piston to generate high pressure. That pressure is then transmitted to a much larger piston.

- Example: Imagine a system operating at 2,000 PSI.

- If that pressure acts on a piston with a surface area of 5 square inches, the output force is 10,000 pounds (5 tons).

- If that same 2,000 PSI acts on a larger piston with a surface area of 25 square inches, the output force becomes 50,000 pounds (25 tons).

The pressure (PSI) stayed the same, but by increasing the piston area, we dramatically multiplied the output force.

Understanding the Trade-offs and Misconceptions

It's crucial to avoid common pitfalls when thinking about hydraulic ratings.

Why a Machine's Weight Is Irrelevant

The provided information that a press weighs 20 kg is not useful for determining its force.

The weight of a press relates to its frame, materials, and overall size. It gives no information about its pump's capability (PSI) or the size of its internal piston (area). A lightweight press could be designed for extremely high pressure, just as a heavy one could be designed for lower pressure.

You Cannot Convert PSI Directly to Tons

There is no universal conversion factor between PSI and tons of force.

Saying a system runs at "3,000 PSI" tells you nothing about its force output unless you also know the piston's surface area. Anyone claiming a direct conversion is leaving out the most critical part of the equation.

How to Evaluate a Hydraulic Press

Focus on the right numbers for the right goal. By understanding the distinction between pressure and force, you can properly assess any hydraulic system.

- If your primary focus is getting a job done: Look for the press's force rating in tons. This is the single most important specification that tells you its practical capability.

- If your primary focus is designing or building a system: You must calculate the required piston area and system pressure (PSI) to achieve your desired output force.

- If your primary focus is troubleshooting or maintenance: You will use a gauge to measure the system's PSI to diagnose whether the pump and valves are performing to specification.

Ultimately, understanding the relationship between pressure, force, and area is the key to mastering any hydraulic application.

Summary Table:

| Concept | Definition | Key Unit | Role in a Hydraulic Press |

|---|---|---|---|

| Pressure (PSI) | Force intensity per unit area | Pounds per Square Inch (PSI) | Created by the pump; the "intensity" in the fluid |

| Force (Tons) | Total output push or squeeze | Tons (1 Ton = 2,000 lbs) | The press's capability to do work (e.g., bending, crushing) |

| Piston Area | Surface area of the hydraulic piston | Square Inches (in²) | The critical multiplier; Force = Pressure × Area |

Need the Right Press for Your Lab's Specific Force Requirements?

Understanding the precise relationship between pressure and force is critical for selecting equipment that delivers accurate, reliable, and safe results. Whether your laboratory work involves material testing, sample preparation, or specialized fabrication, having a press with the correct tonnage rating is essential.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate these technical specifications to find the ideal hydraulic press for your application, ensuring you get the performance and durability your research demands.

Contact us today via the form below to discuss your project requirements and let us provide a solution tailored to your lab's unique challenges.

Get a Personalized Recommendation

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the error range for XRF? Master Your Analytical Accuracy and Precision

- Has the hydraulic press ever failed? Understanding the Two Critical Modes of Failure

- How do you prepare KBr pellets for FTIR analysis? Master the Technique for High-Quality IR Spectra

- What is the maximum operating temperature of a water based hydraulic fluid? Ensure Fire Safety and System Reliability

- How is a laboratory hydraulic press utilized in rubberwood sample preparation for FTIR? Master Precise KBr Pelleting

- Why is a laboratory powder pellet press necessary for shaping CoxAl3FeyOm±δ catalysts? Ensure Reactor Stability

- How strong are hydraulic presses? From 1 to 80,000 tons of scalable force

- What happens if hydraulic pressure is too low? Avoid System Failure and Costly Damage