Blown film extrusion is a process used to produce plastic films by extruding a plastic resin through a die and inflating it into a bubble.

The cost of a blown film extrusion line can vary significantly based on several factors.

A basic entry-level blown film extrusion line with a production capacity of around 20-50 kg/hr typically starts from approximately $20,000 to $30,000.

This cost includes the machinery and initial setup but may not cover additional expenses such as installation, training, and ongoing maintenance.

5 Key Factors to Consider When Estimating the Cost of Blown Film Extrusion

1. Production Capacity and Cost

The cost of a blown film extrusion line is significantly influenced by its production capacity.

Entry-level lines with a capacity of 20-50 kg/hr typically range from $20,000 to $30,000.

Higher production capacities or more advanced models can cost significantly more.

2. Equipment Quality and Features

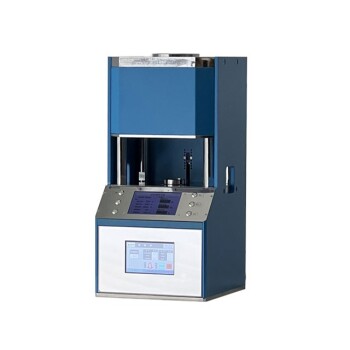

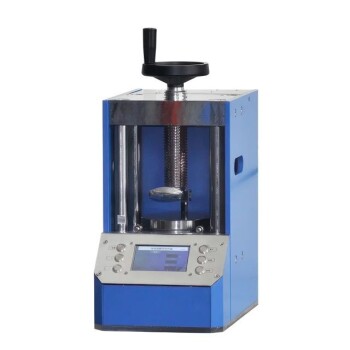

The quality of the equipment and the technology integrated into the extrusion line can greatly affect the price.

Features such as advanced control systems, energy-efficient designs, and durability can increase the cost.

Higher-quality equipment often results in better product quality and longer operational life.

3. Additional Costs

Initial purchase price is not the only cost to consider.

Installation, operator training, and ongoing maintenance and repairs can add to the total cost.

These additional costs should be factored into the budget to ensure smooth operation and longevity of the equipment.

4. Market and Supplier Variability

Prices can vary based on the supplier and geographic location.

Comparing multiple suppliers and understanding their service offerings, warranties, and support can help in making a more informed decision.

Market trends and economic conditions can also influence pricing.

5. Future Scalability and Upgrades

Considering future needs for scaling up production or upgrading technology can be important.

Investing in a system that can be easily upgraded or expanded can save costs in the long run.

This foresight can prevent the need for complete replacement of equipment as production needs grow.

In summary, while the base cost of a blown film extrusion line can start from $20,000 to $30,000 for an entry-level model, the total investment should consider all associated costs and future needs.

Careful planning and research into equipment quality, supplier reliability, and potential for scalability can ensure a cost-effective and efficient operation.

Continue Exploring, Consult Our Experts

Discover how our tailored blown film extrusion solutions can transform your production capabilities.

With a range of options starting from $20,000 to $30,000, and our commitment to quality, efficiency, and scalability, let KINTEK SOLUTION be your partner in success.

Don't miss out on expert advice and the latest market insights—contact us now to elevate your extrusion process!