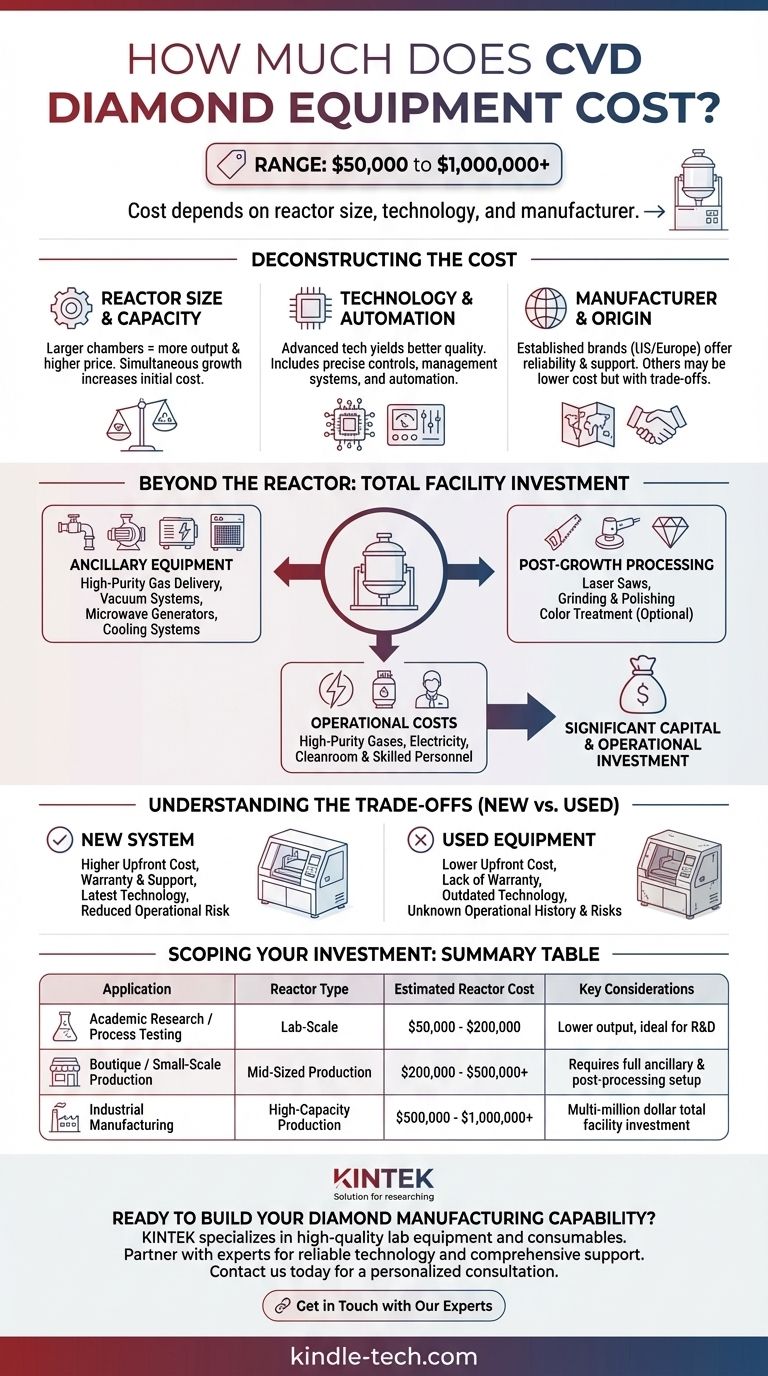

The cost of CVD diamond equipment varies dramatically, ranging from tens of thousands of dollars for small research units to well over a million for high-capacity industrial production systems. The final price is determined by the reactor's size, technological sophistication, and manufacturer.

A single CVD reactor is only one part of a much larger capital investment. To accurately budget for diamond manufacturing, you must account for the full ecosystem of ancillary systems, post-processing machinery, and significant operational costs.

Deconstructing the Cost of a CVD Reactor

The primary piece of equipment is the Microwave Plasma Chemical Vapor Deposition (MPCVD) reactor. Its price is not a single figure but a reflection of its capabilities and features.

Reactor Size and Capacity

The single biggest factor influencing cost is the size of the growth chamber and its production capacity. A larger chamber can hold more diamond "seeds," allowing for the simultaneous growth of numerous stones, which drastically increases output and the initial price of the machine.

A small reactor for academic research or process development might cost between $50,000 and $200,000. In contrast, a large-scale, high-capacity production reactor designed for commercial jewelry manufacturing can easily exceed $500,000 to $1,000,000+.

Technology and Automation

Modern CVD reactors are complex systems. Higher costs are associated with more advanced technology that yields better quality and consistency.

Features that increase the price include ultra-precise gas flow controllers, sophisticated temperature and pressure management systems, and advanced automation software. These elements are critical for controlling the growth process to produce high-clarity, desirable diamonds, minimizing costly errors.

Manufacturer and Origin

The equipment's manufacturer and country of origin play a significant role in its cost. Established manufacturers from the United States or Europe often command higher prices due to their reputation for reliability, customer support, and access to the latest patented technology.

Conversely, equipment from manufacturers in China or India may offer a lower initial purchase price, but this can come with trade-offs in build quality, software sophistication, and post-sale support.

Beyond the Reactor: Total Facility Investment

Thinking that the reactor is your only major expense is a critical oversight. A functional CVD diamond production facility requires a substantial investment in supporting infrastructure.

Essential Ancillary Equipment

The CVD reactor cannot operate in isolation. You must budget for several other key systems:

- High-Purity Gas Delivery: Complex systems to handle and mix gases like methane (CH₄) and hydrogen (H₂).

- Vacuum Systems: Powerful pumps to create the necessary low-pressure environment inside the reactor.

- High-Power Microwave Generators: The energy source that creates the plasma.

- Cooling Systems: Industrial chillers to manage the immense heat generated during the process.

These ancillary systems can add tens or even hundreds of thousands of dollars to the total setup cost.

Post-Growth Processing

The diamond that comes out of the reactor is a rough, unfinished stone. Transforming it into a marketable gem requires another line of equipment:

- Laser Saws: For precisely cutting the rough diamond.

- Grinding and Polishing Machines: To facet the diamond and bring out its brilliance.

- Color Treatment Systems (Optional): Some producers use post-growth treatments like HPHT (High-Pressure High-Temperature) to enhance or change the diamond's color.

Operational and Infrastructure Costs

Finally, ongoing operational costs are significant. This includes the high price of industrial-grade purity gases, an extremely large electricity bill, and the need for a cleanroom environment. You also need highly skilled personnel, such as physicists and engineers, to operate and maintain the equipment.

Understanding the Trade-offs

When planning your investment, you will face a classic dilemma: purchasing new versus used equipment.

The Appeal of the Used Market

The primary benefit of buying used CVD equipment is a significantly lower upfront cost. This can make entry into the market seem more accessible for operations with limited capital.

The Inherent Risks of Used Equipment

However, this lower cost comes with substantial risks. Used reactors often lack a warranty or manufacturer support, leaving you vulnerable to costly downtime. You may be acquiring outdated technology that produces lower-quality diamonds, and the machine's operational history is often unknown, hiding potential defects.

The Security of a New System

Investing in new equipment from a reputable manufacturer provides a warranty, technical support, and access to the latest, most efficient technology. While the initial investment is much higher, it significantly reduces the risk of operational failure and ensures you are producing a competitive product.

Scoping Your Investment

To determine your required budget, you must first define your goal.

- If your primary focus is academic research or process testing: A smaller, lab-scale reactor is your most cost-effective entry point.

- If your primary focus is boutique or small-scale commercial production: Budget for at least one mid-sized production reactor plus the full suite of ancillary and post-processing equipment.

- If your primary focus is large-scale industrial manufacturing: You must plan for a multi-million dollar investment covering multiple high-capacity reactors and a fully integrated production facility.

Understanding the full scope of costs, from the reactor to the finished gem, is the first step in building a viable diamond manufacturing operation.

Summary Table:

| Application | Reactor Type | Estimated Reactor Cost | Key Considerations |

|---|---|---|---|

| Academic Research / Process Testing | Lab-Scale | $50,000 - $200,000 | Lower output, ideal for R&D |

| Boutique / Small-Scale Production | Mid-Sized Production | $200,000 - $500,000+ | Requires full ancillary & post-processing setup |

| Industrial Manufacturing | High-Capacity Production | $500,000 - $1,000,000+ | Multi-million dollar total facility investment |

Ready to build your diamond manufacturing capability?

Navigating the complex landscape of CVD diamond equipment requires a partner with deep expertise. At KINTEK, we specialize in providing high-quality lab equipment and consumables, serving the precise needs of laboratories and production facilities.

We can help you select the right reactor and ancillary systems for your specific goals—whether for research, boutique production, or industrial scale-up. Our team ensures you get reliable technology and comprehensive support to maximize your investment and minimize operational risks.

Contact us today to discuss your project requirements and receive a personalized consultation. Let KINTEK be your trusted partner in bringing your diamond production vision to life.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- How do CVD diamonds grow? A Step-by-Step Guide to Lab-Grown Diamond Creation

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering

- How is diamond coating made? A Guide to CVD and PVD Methods