The required pressure for a hydraulic press is not a single value; it is entirely dependent on the material you are working with and the operation you are performing. The most critical mistake is to confuse the internal hydraulic system pressure (measured in PSI) with the exerted force on the workpiece (measured in tons). The force, or tonnage, is the correct metric to focus on, and it is a product of the system pressure and the surface area of the piston.

The central challenge is not to find a specific hydraulic pressure number, but to correctly calculate the force (tonnage) your job requires. This calculation is based on the material's properties and the geometry of the operation, which then dictates the press specifications you need.

The Two Metrics You Must Understand

To make an informed decision, you must first distinguish between the internal workings of the press and the output it delivers. They are related but are not the same thing.

System Pressure (PSI/Bar)

This is the pressure of the hydraulic fluid inside the machine's circuits, generated by the pump. It is a key specification of the press itself.

A press might have a maximum system pressure of 3,000 PSI, but this number is meaningless without knowing the size of the cylinder it acts upon.

Exerted Force (Tonnage)

This is the actual force the press applies to the workpiece. It is the metric that matters for your application—the "work" being done.

Tonnage is the standard industry measurement for a press's capability. A 50-ton press is one that can exert 100,000 pounds of force.

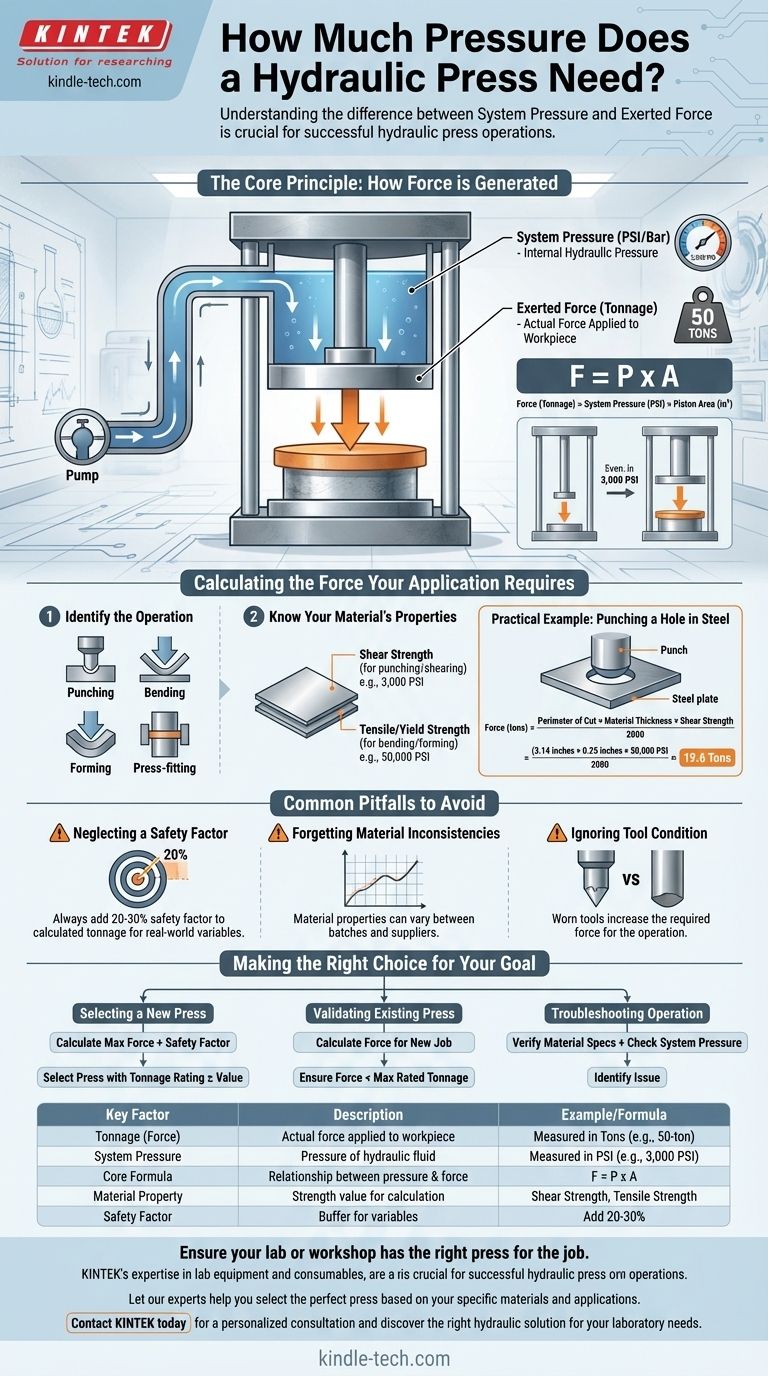

The Core Principle: How Force is Generated

The relationship between system pressure and exerted force is governed by a fundamental principle of physics. Understanding this is key to understanding any hydraulic system.

The Fundamental Formula: F = P x A

The formula is Force = Pressure × Area.

- Force (F): The tonnage the press exerts on your part.

- Pressure (P): The system pressure of the hydraulic fluid (PSI).

- Area (A): The surface area of the piston face inside the main cylinder (in square inches).

This explains why two presses with the same 3,000 PSI system pressure can have vastly different tonnage ratings. A press with a larger cylinder piston has more area, so it multiplies that pressure into a greater force.

Calculating the Force Your Application Requires

To determine what press you need, you must first calculate the force your specific job demands. This depends entirely on what you are trying to accomplish.

Step 1: Identify the Operation

The type of work dictates the calculation. The most common operations are punching, bending, forming, and press-fitting. Each requires overcoming a different material property.

Step 2: Know Your Material's Properties

You cannot calculate the required force without knowing the strength of your material. For punching and shearing, the critical value is the Shear Strength. For bending and forming, it's the Tensile Strength or Yield Strength.

These values are found on the material's technical data sheet and are typically measured in pounds per square inch (PSI).

A Practical Example: Punching a Hole in Steel

Punching or shearing is one of the most common press applications. The formula to estimate the required force is straightforward.

Force (in tons) = (Perimeter of Cut × Material Thickness × Shear Strength) / 2000

- Perimeter of Cut: The length of the line being sheared. For a 1-inch diameter hole, this is the circumference (π × 1" ≈ 3.14 inches).

- Material Thickness: The thickness of the material in inches.

- Shear Strength: The material's shear strength in PSI. A common value for mild steel is around 50,000 PSI.

- / 2000: This converts the final result from pounds into U.S. tons.

For example, punching a 1-inch diameter hole in 0.25-inch thick mild steel would require approximately 20 tons of force (3.14" × 0.25" × 50,000 PSI / 2000 lbs/ton ≈ 19.6 tons).

Common Pitfalls to Avoid

Basing a decision on incomplete information is a frequent and costly error. Always consider these factors.

Neglecting a Safety Factor

Calculations provide a theoretical minimum. Real-world material properties can vary, and tooling can become dull.

Always add a safety factor of at least 20-30% to your calculated tonnage. For a 20-ton job, you should use a press rated for at least 25 tons.

Forgetting Material Inconsistencies

The shear or tensile strength of a material is not perfectly uniform. Different batches or suppliers can have slight variations that impact the required force. Your safety factor helps account for this.

Ignoring Tool Condition

A sharp punch requires significantly less force than a dull one. As your tooling wears, the force required to perform the operation increases. If your press is sized too closely to the minimum, you will see failures as tools wear.

Making the Right Choice for Your Goal

Your approach depends on whether you are acquiring new equipment or validating an existing process.

- If your primary focus is selecting a new press: Calculate the force needed for your most demanding application, add a robust safety factor, and then select a press with a tonnage rating that meets or exceeds that value.

- If your primary focus is validating a press for a new job: Calculate the force required for the new material and operation, and ensure it is comfortably below the maximum rated tonnage of your existing machine.

- If your primary focus is troubleshooting a failing operation: First, verify that the material being used matches the specifications you planned for. Second, confirm your press's hydraulic system is achieving its specified pressure to rule out a maintenance issue.

A precise understanding of your material and operational forces is the only way to ensure a reliable and effective process.

Summary Table:

| Key Factor | Description | Example/Formula |

|---|---|---|

| Tonnage (Force) | The actual force applied to the workpiece. The critical metric. | Measured in Tons (e.g., 50-ton press). |

| System Pressure | Pressure of the hydraulic fluid inside the press. | Measured in PSI (e.g., 3,000 PSI). |

| Core Formula | Relationship between pressure and force. | Force (tons) = Pressure (PSI) × Piston Area (in²) / 2000 |

| Material Property | The strength value used for calculation. | Shear Strength (for punching), Tensile Strength (for forming). |

| Safety Factor | Buffer for real-world variables. | Add 20-30% to calculated tonnage. |

Ensure your lab or workshop has the right press for the job. Accurately calculating tonnage is critical for successful punching, bending, and forming operations. KINTEK specializes in lab equipment and consumables, serving laboratory and R&D needs with precision hydraulic presses and expert support.

Let our experts help you select the perfect press based on your specific materials and applications. We can guide you through the calculations to ensure reliable, efficient, and safe results.

Contact KINTEK today for a personalized consultation and discover the right hydraulic solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples