To determine the power of a hydraulic press, you must look at its force rating—known as tonnage—not its own physical weight. The 20 kg weight of a press is a measure of its mass and the materials used in its construction, which is almost entirely separate from the immense force it can generate through its hydraulic system.

A hydraulic press's capacity is not determined by its own weight but by a principle called force multiplication. The force it exerts depends on its internal hydraulic system—specifically, the fluid pressure and the relative surface area of its pistons.

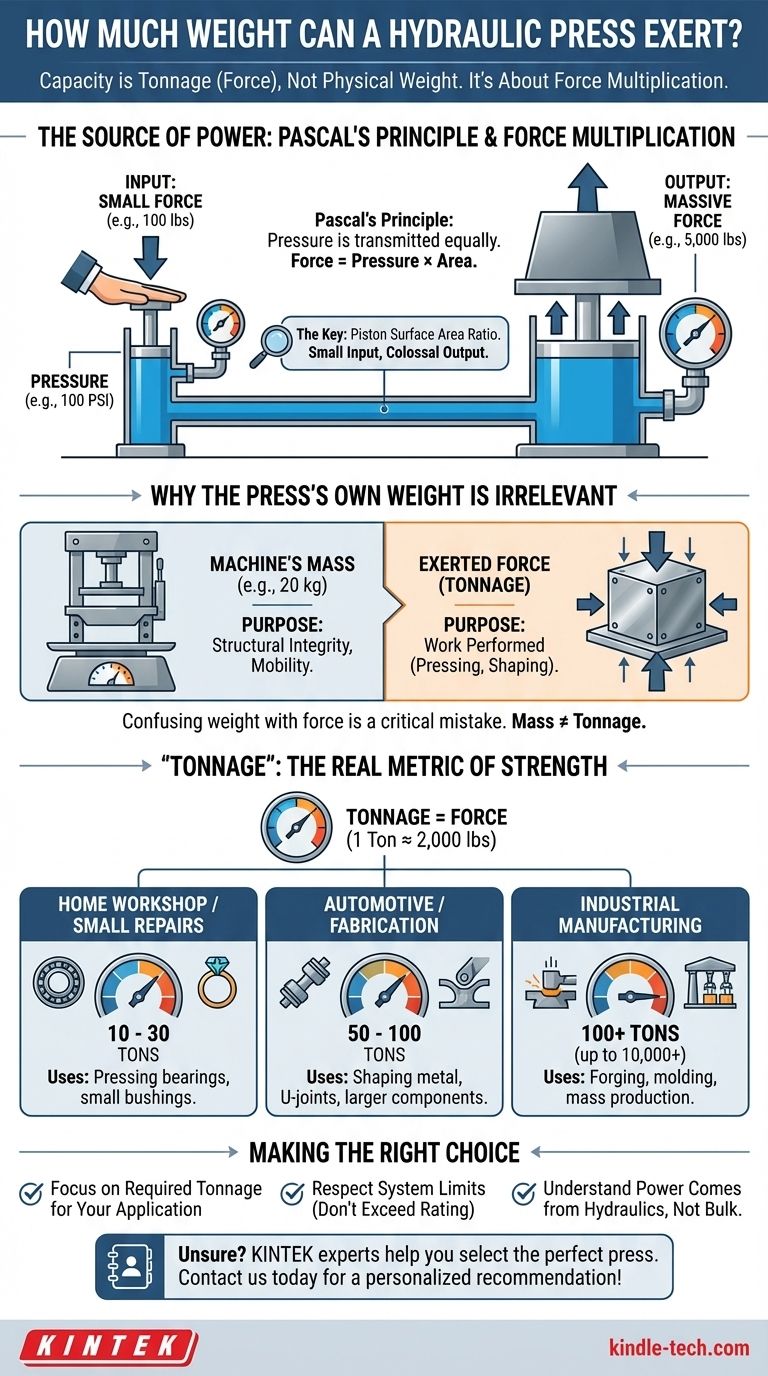

The Source of Power: How Force is Multiplied

The operation of a hydraulic press is governed by a fundamental law of physics known as Pascal's Principle. This principle is the key to understanding how a small amount of effort can be converted into a tremendous output force.

Pascal's Principle in Action

Pascal's Principle states that when pressure is applied to a confined, incompressible fluid (like hydraulic oil), that pressure is transmitted equally throughout the entire fluid.

Imagine the system has two pistons: a small one where you apply force and a large one that does the pressing.

The Input: A Small Force on a Small Piston

When you apply a modest force to the small input piston, you create pressure in the hydraulic fluid. For example, pushing with 100 pounds of force on a 1-square-inch piston creates 100 pounds per square inch (PSI) of pressure.

The Output: A Massive Force from a Large Piston

This same 100 PSI of pressure is now transmitted throughout the fluid, pushing against the much larger output piston. If this output piston has a surface area of 50 square inches, that 100 PSI is now acting on every single one of those inches.

The resulting output force would be 100 PSI * 50 square inches = 5,000 pounds of force.

The Key is the Piston Ratio

The magic of the hydraulic press is in the size difference between the two pistons. This force multiplication is directly proportional to the ratio of their surface areas. A small input can control a colossal output.

Why the Press's Own Weight is Irrelevant to Force

Confusing the weight of the machine with the force it exerts is a common but critical misunderstanding. The two values measure entirely different things.

Mass vs. Exerted Force

The 20 kg weight of the press is its mass—the amount of matter it contains. This matters for shipping it or moving it around the workshop. The pressing force, or tonnage, is the amount of work it can perform.

The True Role of the Machine's Weight

The weight and bulk of the press's frame serve a different purpose: structural integrity. The frame must be heavy and strong enough to withstand the immense internal forces it generates without bending, flexing, or failing.

"Tonnage": The Real Metric of a Press's Strength

When evaluating a hydraulic press, the single most important specification is its tonnage rating.

What is Tonnage?

Tonnage is a unit of force, not weight. One ton of force is equivalent to 2,000 pounds of force (or approximately 907 kilograms-force). This rating tells you the maximum force the press can safely exert.

Typical Tonnage Ranges

The capacity of hydraulic presses varies enormously based on their intended use:

- Benchtop Presses: Often rated between 1 and 30 tons, used for small jobs like pressing bearings or bushings.

- Automotive/Fabrication Presses: Typically range from 20 to 100 tons for handling larger components and shaping metal.

- Industrial Presses: Can exceed 10,000 tons, used for forging, molding, and large-scale manufacturing.

Common Pitfalls to Avoid

Understanding the principles helps you avoid costly mistakes when selecting or using a hydraulic press.

The Primary Misconception

The most common error is equating the machine's physical weight with its pressing capability. As we've established, a lightweight press can still generate enormous force if its hydraulic system is designed for it.

Ignoring System Limits

The tonnage rating represents the limit of the entire system. Pushing a press beyond its rating risks catastrophic failure of the frame, hydraulic seals, or cylinders, which is extremely dangerous. Always respect the manufacturer's stated capacity.

Making the Right Choice for Your Goal

To select the right press, ignore its shipping weight and focus entirely on the tonnage required for your specific applications.

- If your primary focus is a home workshop or small repairs: A benchtop press with a 10 to 30-ton rating is typically more than sufficient for tasks like jewelry making or removing small bearings.

- If your primary focus is automotive or fabrication work: A floor-standing press in the 50 to 100-ton range provides the power needed for shaping metal and handling larger vehicle components.

- If your primary focus is industrial manufacturing: You will need a specialized press rated for hundreds or thousands of tons, engineered specifically for your production process.

Understanding that a press's power comes from hydraulic principles, not its physical bulk, is the key to choosing the correct tool for the job.

Summary Table:

| Application | Recommended Tonnage | Common Uses |

|---|---|---|

| Home Workshop / Small Repairs | 10 - 30 Tons | Pressing bearings, jewelry making, small bushings |

| Automotive / Fabrication | 50 - 100 Tons | Shaping metal, removing large bearings, pressing U-joints |

| Industrial Manufacturing | 100+ Tons (up to 10,000+) | Forging, molding, large-scale production |

Unsure which hydraulic press is right for your project?

KINTEK specializes in providing reliable lab equipment and consumables. Our experts can help you select the perfect press based on your specific needs, ensuring you get the right tonnage for tasks ranging from delicate lab work to robust fabrication.

Contact us today via our [#ContactForm] to discuss your requirements and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Importance of Vacuum Infusion or Hydraulic Press in Bio-Based Composites? Unlock Superior Strength and Precision

- What is a KBr press? Creating Transparent Pellets for Accurate FT-IR Analysis

- How is a laboratory hydraulic press used for stainless steel surface modification? Prevent Organic Acid Corrosion

- What is the difference between mechanical power press and hydraulic press? High-Speed vs. Controlled Force

- How does a laboratory hydraulic press ensure product quality in NFPC preparation? Achieve Superior Composite Strength

- What are the limits of detection for XRF? Understanding Sensitivity for Accurate Analysis

- What is the purpose of using stainless steel molds and laboratory hydraulic presses? Ensure Precise Ionic Conductivity

- What is the uniaxial pressing method? A Guide to High-Speed, Cost-Effective Powder Compaction