Properly using an electrode holder is a matter of procedural precision, focused on protecting both your sample and the holder itself to ensure data integrity. The most critical steps involve securely mounting your sample without damaging it, choosing a non-corrosive electrolyte, and, most importantly, ensuring only the test sample—and never the clip mechanism—is submerged in the solution.

Using an electrode holder correctly is not just about physically securing a sample. It's about recognizing that the holder is an active component of your measurement circuit, where the smallest procedural error, like submerging the clip, can contaminate your experiment and permanently damage your equipment.

The Role of the Electrode Holder

An electrode holder is more than just a mechanical clamp; it is a critical component in your electrochemical setup.

Function as the Working Electrode

In most electrochemical experiments, the sample holder assembly functions as the Working Electrode (WE). This is the electrode where the reaction of interest occurs.

This means the holder is an active part of the electrical circuit, making its condition and proper use directly impact the accuracy and reliability of your results.

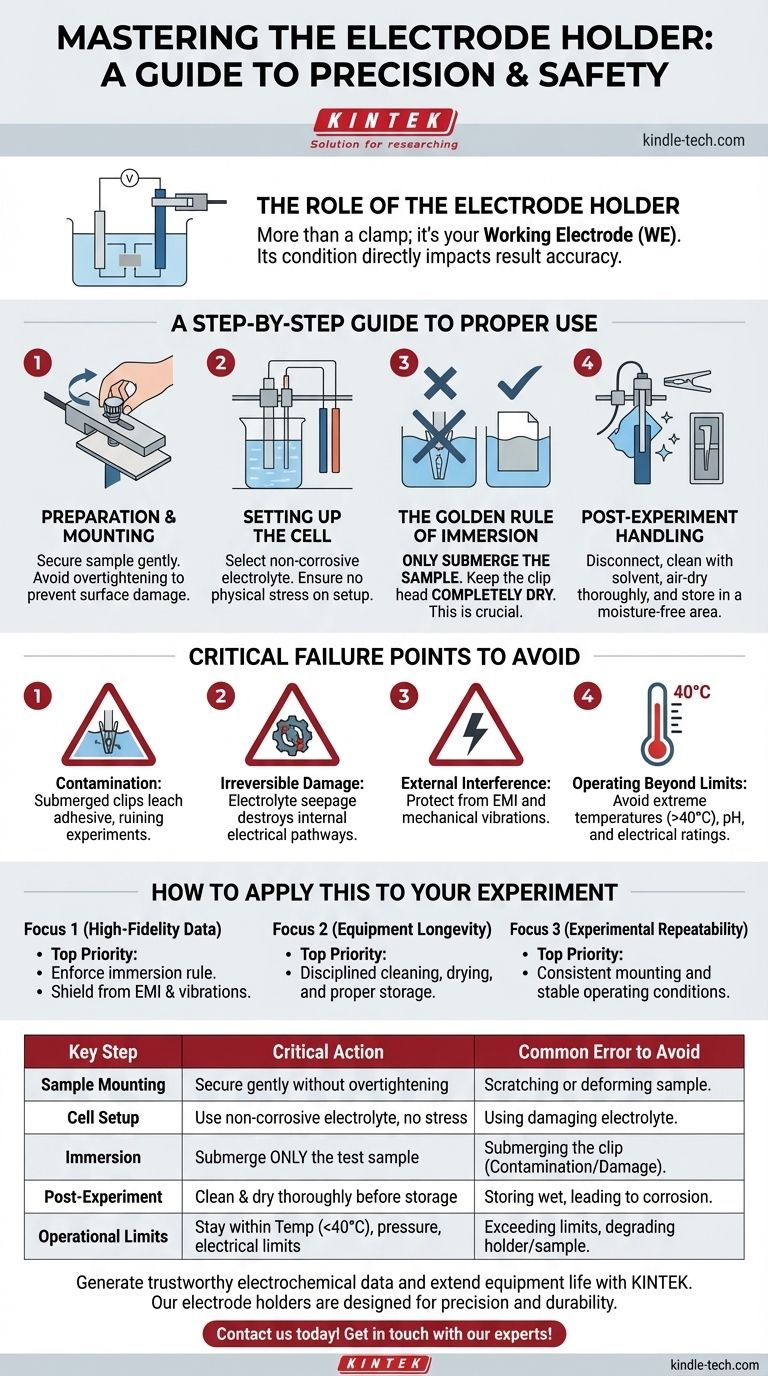

A Step-by-Step Guide to Proper Use

Following a strict procedure minimizes variables and protects your equipment.

Preparation and Sample Mounting

Begin by carefully installing your test sample into the clip head.

Tighten the screw just enough to ensure a secure electrical and physical connection. Overtightening can scratch or damage the sample surface, altering its electrochemical properties.

Setting Up the Electrochemical Cell

Select an electrolyte that is non-corrosive to your sample and, just as importantly, to the conductive materials of the holder itself.

Position the holder so the sample is correctly placed relative to the reference and counter electrodes, ensuring no part of the setup is under physical stress.

The Golden Rule of Immersion

Only the test sample sheet should be immersed in the electrolyte. The clip head and its associated components must remain completely out of the solution at all times.

This rule is non-negotiable and is the most common point of failure.

Post-Experiment Handling and Storage

After the experiment, disconnect the connecting wires from the apparatus.

Carefully remove the sample. Clean the electrode holder and the sample separately using an appropriate solvent, then allow them to air-dry completely or gently pat them with filter paper.

Store the clean, dry holder in a moisture-free, well-ventilated area to prevent corrosion and ensure it's ready for the next use.

Critical Failure Points to Avoid

Understanding what can go wrong is key to preventing it. The primary risks are contamination and irreversible damage stemming from improper immersion or harsh conditions.

Contamination from Clip Immersion

The solder points and internal components of the clip head are often sealed with an adhesive.

If submerged, the electrolyte can dissolve this adhesive over time. This leaches contaminants directly into your solution, compromising your experiment and producing unreliable data.

Irreversible Electrode Damage

Prolonged or repeated immersion allows the electrolyte to seep past the damaged seal and into the body of the holder.

This internal corrosion will destroy the electrical pathways, leading to signal failure and rendering the expensive holder useless.

The Impact of External Interference

Because the holder is part of a sensitive measurement circuit, it's susceptible to outside influence.

Protect the setup from electromagnetic interference (EMI) and static by using shielding or grounding. Avoid mechanical vibrations that could disturb the electrochemical interface and affect measurements.

Operating Beyond Safe Limits

Adhere strictly to the holder's operational limits. Most are designed for use at normal atmospheric pressure and at temperatures not exceeding 40°C.

Avoid extreme pH levels and do not exceed the rated current and voltage limits, as this can degrade both the holder and your sample.

How to Apply This to Your Experiment

Your specific focus will determine which best practices are most critical to your success.

- If your primary focus is high-fidelity data: Your top priority is enforcing the immersion rule to prevent contamination and shielding your setup from all EMI and mechanical vibrations.

- If your primary focus is equipment longevity: Your discipline during post-experiment cleaning, drying, and proper storage is paramount to preventing long-term corrosion.

- If your primary focus is experimental repeatability: Concentrate on consistent sample mounting and maintaining stable operating conditions like temperature and stirring speed across all your tests.

Mastering the use of your electrode holder is the foundation for generating trustworthy and repeatable electrochemical results.

Summary Table:

| Key Step | Critical Action | Common Error to Avoid |

|---|---|---|

| Sample Mounting | Secure sample without overtightening to avoid surface damage. | Scratching or deforming the sample. |

| Cell Setup | Use a non-corrosive electrolyte and position holder without stress. | Using an electrolyte that damages the holder. |

| Immersion (Golden Rule) | Submerge only the test sample, keeping the clip head dry. | Submerging the clip, which causes contamination and damage. |

| Post-Experiment | Clean and dry holder and sample thoroughly before storage. | Storing equipment while wet, leading to corrosion. |

| Operational Limits | Stay within temperature (<40°C), pressure, and electrical limits. | Exceeding limits, degrading the holder and sample. |

Generate trustworthy electrochemical data and extend the life of your equipment with the right tools and expertise. KINTEK specializes in high-quality lab equipment and consumables for all your electrochemical needs. Our electrode holders are designed for precision and durability, helping you achieve reliable, repeatable results. Contact us today to find the perfect solution for your laboratory. Get in touch with our experts!

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Customizable XRD Sample Holders for Diverse Research Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Button Battery Case for Battery Lab Applications

People Also Ask

- What are the storage requirements for the PTFE electrode stand after cleaning? Preserve Purity and Equipment Longevity

- Why is it necessary to utilize PTFE sample holders in electroless nickel plating? Ensure Process Integrity

- What materials are the sample holders made of? Engineered with PTFE and PEEK for Purity

- How can corrosion of the sample holder be prevented when using corrosive chemicals? Protect Your Lab's Integrity

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination