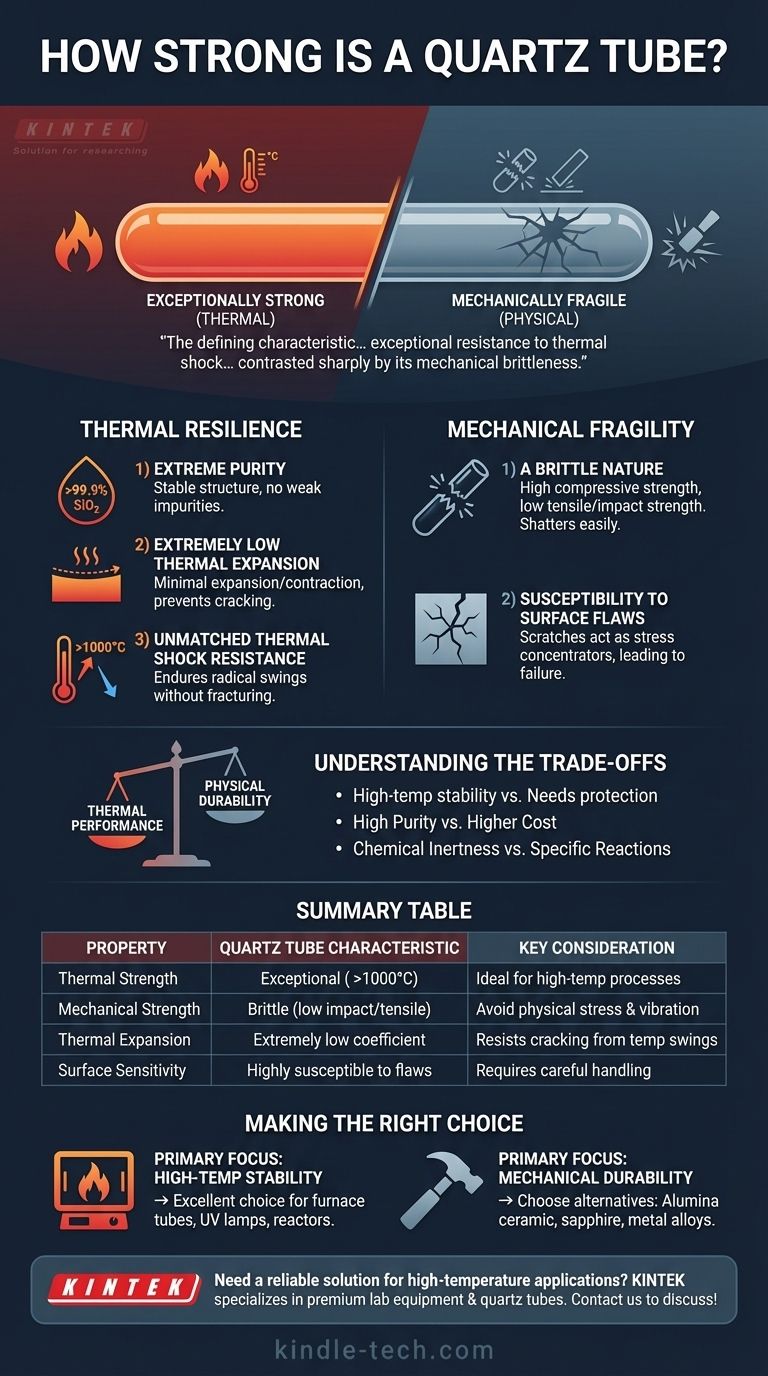

A quartz tube's strength is a tale of two extremes. It possesses exceptional thermal strength, capable of withstanding immense temperature changes that would shatter ordinary glass. However, it is also mechanically brittle, meaning it can easily fracture from physical impact or bending stress.

The defining characteristic of a quartz tube is its exceptional resistance to thermal shock and high temperatures, contrasted sharply by its mechanical brittleness. Understanding this duality is critical for selecting it for the right application.

The Source of Its Thermal Resilience

The "strength" most often praised in quartz tubing refers to its incredible ability to handle heat and rapid temperature changes. This resilience comes from its fundamental material properties.

Extreme Purity

High-purity fused quartz is typically over 99.9% silicon dioxide (SiO₂). This purity contributes to a highly stable and predictable material structure, free from the impurities that can create weak points in other ceramics or glasses.

Extremely Low Thermal Expansion

The primary reason quartz resists thermal shock is its very low coefficient of thermal expansion. This means the material barely expands when heated or contracts when cooled.

When a material changes temperature rapidly, different parts of it expand or contract at different rates, creating internal stress. Because quartz moves so little, this stress never builds to a level that causes it to crack.

Unmatched Thermal Shock Resistance

This low thermal expansion allows a quartz tube to endure radical temperature swings. It can be heated to over 1000°C (1832°F) and then rapidly cooled to room temperature without fracturing, a feat that is impossible for most other materials.

The Critical Weakness: Mechanical Fragility

While thermally robust, a quartz tube is mechanically fragile. Its strength profile is highly specific and does not extend to physical durability.

A Brittle Nature

Like common glass, quartz is a brittle material. It has high compressive strength but very low tensile and impact strength.

This means it can handle uniform pressure well, but it will shatter from a sharp impact, bending force, or significant vibration.

Susceptibility to Surface Flaws

The integrity of a quartz tube is highly dependent on its surface condition. Scratches, chips, or even microscopic flaws can act as stress concentrators, creating a starting point for a crack to propagate and lead to catastrophic failure under minimal load.

Understanding the Trade-offs

Choosing quartz means accepting a clear set of compromises. Its specialized strengths come with equally significant limitations.

Thermal Performance vs. Physical Durability

This is the central trade-off. You gain world-class performance in high-temperature and thermal-cycling environments. In exchange, you must ensure the tube is protected from any form of mechanical shock, vibration, or stress.

High Purity vs. High Cost

The manufacturing process required to achieve the high purity of fused quartz makes it more expensive than alternatives like borosilicate glass or many technical ceramics.

Chemical Inertness vs. Specific Reactions

Quartz is highly resistant to acids and neutral substances. However, it can be attacked by hydrofluoric acid and phosphoric acid, and it can react with alkaline substances at high temperatures.

Making the Right Choice for Your Application

Use this understanding to determine if quartz is the appropriate material for your specific goal.

- If your primary focus is high-temperature stability or thermal shock resistance: Quartz is an excellent choice for applications like furnace process tubes, UV lamps, and chemical reactors where it will be held stationary.

- If your primary focus is mechanical durability and impact resistance: You must choose a different material, such as alumina ceramic, sapphire, or a suitable metal alloy, for any application involving physical stress or vibration.

By aligning the unique properties of quartz with the demands of your task, you ensure both operational success and safety.

Summary Table:

| Property | Quartz Tube Characteristic | Key Consideration |

|---|---|---|

| Thermal Strength | Exceptional (withstands >1000°C, rapid cooling) | Ideal for high-temperature processes |

| Mechanical Strength | Brittle (low impact/tensile strength) | Avoid physical stress and vibration |

| Thermal Expansion | Extremely low coefficient | Resists cracking from temperature swings |

| Surface Sensitivity | Highly susceptible to flaws/scratches | Requires careful handling and inspection |

Need a reliable solution for high-temperature applications? KINTEK specializes in premium lab equipment and consumables, including quartz tubes designed for superior thermal performance. Our expertise ensures you get the right materials for your laboratory's specific needs, maximizing both safety and efficiency. Contact us today to discuss how our quartz tubes can enhance your processes!

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What are the primary functions of high-precision tube furnaces in graphene growth? Achieve Defect-Free GS Synthesis

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis