A hydraulic press is only as safe as the procedures governing its use. While many presses incorporate safety features like built-in overload protection, their capacity to generate immense force means that safety is not an inherent quality. Instead, it is a direct result of proper training, consistent maintenance, and operator vigilance.

The immense force generated by a hydraulic press is its greatest asset and its most significant hazard. True safety doesn't come from the machine itself, but from a strict adherence to operational protocols, understanding its mechanical limits, and recognizing the warning signs of a potential failure.

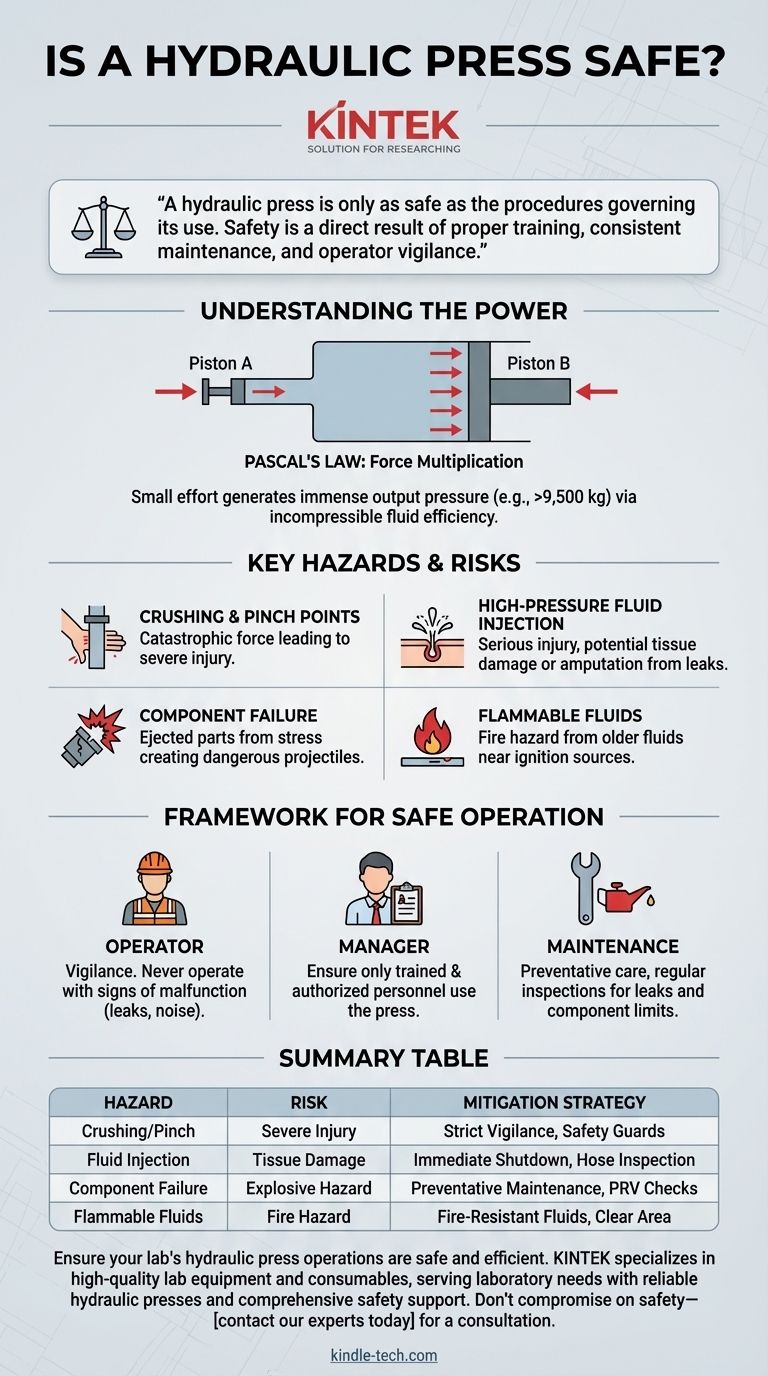

Understanding the Source of Power and Risk

To appreciate the safety requirements of a hydraulic press, it's essential to first understand how it achieves such incredible force. This knowledge clarifies why specific precautions are non-negotiable.

The Principle of Force Multiplication

A hydraulic press operates on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted equally throughout that fluid. The machine uses a small piston (the plunger) to apply pressure to hydraulic fluid, which then acts on a much larger piston (the ram).

This difference in area multiplies the initial force dramatically, allowing a small amount of effort to generate many tons of output pressure. This is how a compact machine can exert forces exceeding 9,500 kg or more.

The Role of Incompressible Fluid

The system works because hydraulic fluid is virtually incompressible. When the pump applies pressure, the fluid has nowhere to go but to push against the large piston, transferring energy with very high efficiency. This efficiency, however, means the system is constantly under extreme internal pressure during operation.

Key Hazards of Hydraulic Press Operation

The power of a hydraulic press gives rise to several specific and severe hazards. Understanding these risks is the first step toward mitigating them.

Crushing and Pinch Points

The most obvious danger is the immense crushing force exerted by the ram. Any body part caught between the ram and the working surface will be subjected to catastrophic force, leading to severe injury.

High-Pressure Fluid Injection

A leak in a hydraulic line can release fluid at a pressure high enough to penetrate human skin. This type of injury is extremely serious, often leading to severe tissue damage, amputation, or death if not treated immediately as a surgical emergency.

Component Failure

The high internal pressures place significant stress on the machine's components, including the frame, cylinders, and hoses. If a part fails, it can be ejected with explosive force, creating dangerous projectiles.

Flammable Fluids

While many modern hydraulic fluids are formulated to be fire-resistant, some older or specialized types can be flammable. A leak near an ignition source can create a significant fire hazard.

Understanding the Trade-offs: Built-in Safeguards vs. Operational Risks

The design of a hydraulic press involves balancing its incredible power with features designed to manage risk. However, these features do not eliminate the need for caution.

The Benefit of Overload Protection

Most hydraulic presses have a built-in pressure relief valve. This is a critical safety feature that prevents the system from exceeding its maximum designed pressure, protecting the machine from self-destruction and reducing the risk of catastrophic component failure.

The Danger of Fluid Leaks

A small drip of hydraulic fluid is more than a housekeeping issue; it is a critical warning sign. It indicates a potential failure point in a high-pressure system and must be addressed immediately by trained personnel before the machine is used again.

The Speed vs. Force Limitation

Hydraulic presses typically operate at a lower speed than mechanical presses. This slower speed can be a safety advantage, giving the operator more time to react. However, it should never be mistaken for a lack of force.

A Framework for Safe Operation

Ensuring safety requires a clear understanding of responsibilities, whether you are operating the machine or managing the environment around it. The following guidelines are critical.

- If you are an operator: Your primary responsibility is vigilance. Never operate a machine that shows signs of malfunction like leaks, unusual noise, or excessive vibration.

- If you are a manager or supervisor: Your priority must be ensuring that only formally trained and authorized personnel are permitted to use the press.

- If you are responsible for maintenance: Your focus is preventative care, regularly inspecting for fluid leaks and ensuring all components are within their operational limits.

Ultimately, a well-maintained hydraulic press in the hands of a trained and attentive operator is a safe and powerful tool.

Summary Table:

| Hazard | Risk | Mitigation Strategy |

|---|---|---|

| Crushing/Pinch Points | Severe injury from ram force | Strict operator vigilance, use of safety guards |

| High-Pressure Fluid Injection | Tissue damage, amputation | Immediate shutdown for leaks, regular hose inspection |

| Component Failure | Explosive projectile hazard | Preventative maintenance, pressure relief valve checks |

| Flammable Fluids | Fire hazard | Use of fire-resistant fluids, keep area clear of ignition sources |

Ensure your lab's hydraulic press operations are safe and efficient. KINTEK specializes in high-quality lab equipment and consumables, serving laboratory needs with reliable hydraulic presses and comprehensive safety support. Don't compromise on safety—contact our experts today for a consultation on the right press for your application and guidance on proper safety protocols.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy