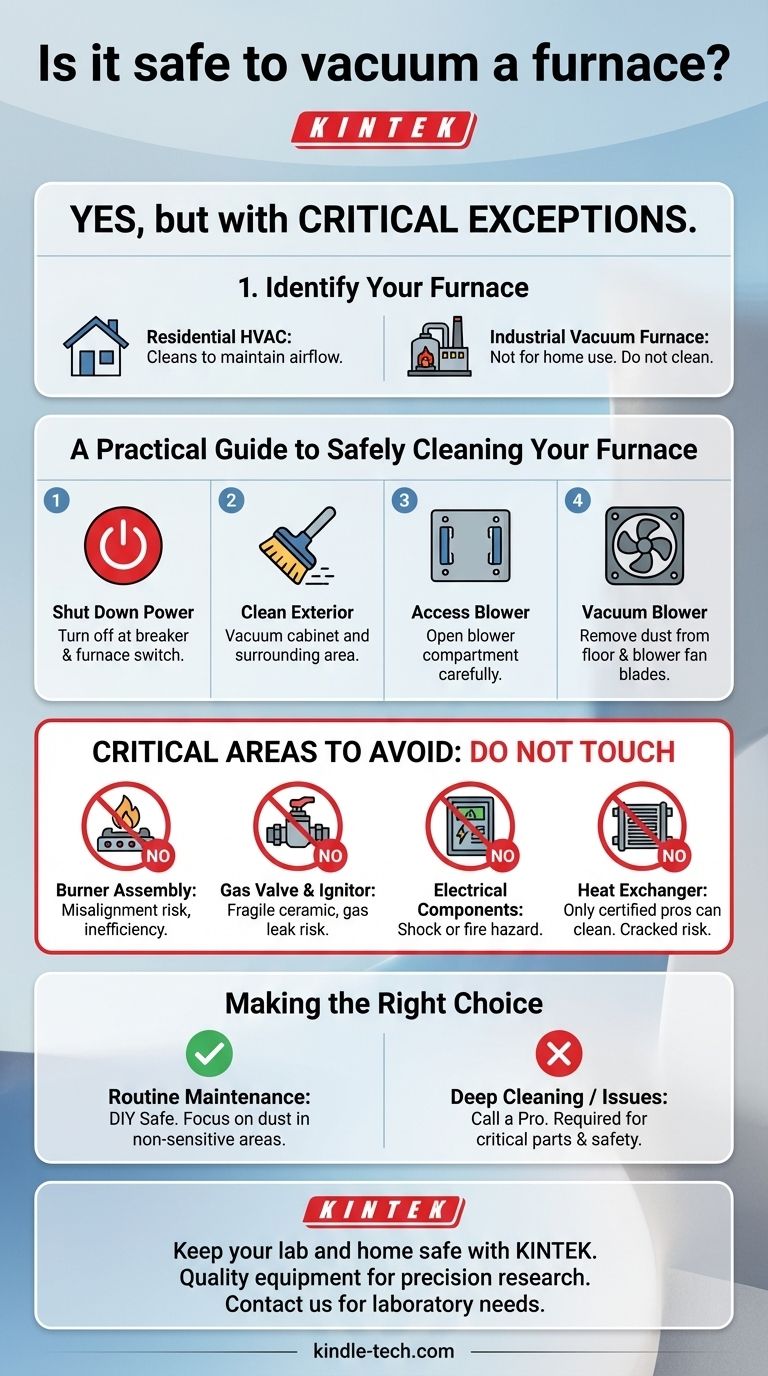

Yes, it is generally safe to vacuum certain parts of your residential furnace, but this comes with critical exceptions. You can safely use a standard vacuum with a brush attachment to clean the exterior of the unit, the floor of the interior compartments, and the blower fan. However, you must first completely shut off all power to the furnace and avoid touching any electrical components, wiring, or the burner assembly.

The core principle of DIY furnace cleaning is to remove dust and debris from non-sensitive areas to improve airflow and efficiency. The goal is not to service or repair the furnace; critical components like burners, gas valves, and all electronics should only be handled by a certified HVAC professional.

The First Step: Identify Your Furnace Type

Before you begin, it's vital to understand that the term "furnace" can be misleading. Online search results often confuse two vastly different pieces of equipment.

Residential HVAC Furnace

This is the unit in your home that provides heat. Cleaning is focused on removing household dust and debris to maintain airflow and efficiency. This is the furnace this guide refers to.

Industrial Vacuum Furnace

This is a highly specialized piece of industrial equipment used to heat materials to extreme temperatures in a vacuum for processes like brazing or sintering. These are not found in homes and operate under completely different principles.

A Practical Guide to Safely Cleaning Your Furnace

Follow these steps to safely perform basic maintenance. Your primary goal is to remove dust from areas that don't involve fuel or electricity.

Step 1: Completely Shut Down the Power

This is the most critical safety step. First, turn off the furnace at your home's main electrical panel (the breaker box). Second, find the power switch located on or near the furnace itself and turn it off as a redundant safety measure.

Step 2: Clean the Exterior and Surrounding Area

Use a vacuum with a brush attachment to clean the outside of the furnace cabinet and the floor around it. Removing this dust and debris prevents it from being pulled into the system.

Step 3: Access the Blower Compartment

The furnace cabinet usually has one or two removable panels. The blower is typically located in the bottom compartment. These panels may be held by screws or simple clips. Once removed, you will see the blower motor and the squirrel-cage fan.

Step 4: Vacuum the Compartment and Blower Fan

Carefully vacuum the floor of the compartment, removing any accumulated dust. You can also gently use a soft brush attachment to clean the blades of the blower fan. A heavy buildup of dust here can unbalance the fan and reduce airflow.

Critical Areas to Avoid: What Not to Vacuum

Attempting to clean the wrong components can create serious safety hazards, including fire risk, gas leaks, or carbon monoxide exposure. Do not touch, vacuum, or interfere with the following parts.

The Burner Assembly

The burners are precisely engineered to mix fuel and air for clean combustion. Vacuuming them can knock them out of alignment or damage them, leading to inefficient or dangerous operation.

The Gas Valve and Ignitor

The gas valve is a complex safety control, and the ignitor (whether a hot surface ignitor or a pilot light assembly) is often made of fragile ceramic material. Both are easily damaged and are absolutely off-limits for DIY cleaning.

Any Electrical Components or Wiring

Reiterating the most important rule: never let a vacuum tool touch control boards, wiring, or electrical connections. You can easily dislodge a wire or cause a short circuit that prevents the furnace from working or creates a fire hazard.

The Heat Exchanger

The heat exchanger is the metal chamber that separates the toxic combustion gases from the breathable air pushed into your home. It can only be properly inspected and cleaned by a professional who knows how to check it for dangerous cracks or corrosion.

Making the Right Choice for Your Goal

Your approach should depend entirely on your objective.

- If your primary focus is routine annual maintenance: Confidently clean the furnace exterior, the floor of the internal compartments, and the blower fan after shutting off all power.

- If your primary focus is deep cleaning or addressing a performance issue: Your only safe action is to call a qualified and certified HVAC technician for a professional service.

Knowing your limits is the key to keeping your furnace running both safely and efficiently.

Summary Table:

| Action | Safe to DIY? | Notes |

|---|---|---|

| Vacuum exterior & floor around furnace | Yes | Improves airflow and efficiency. |

| Clean blower fan with soft brush | Yes | Remove dust to prevent imbalance. |

| Touch electrical components or wiring | No | Risk of fire or electrical shock. |

| Clean burner assembly or gas valve | No | Can cause gas leaks or CO hazards. |

| Inspect or clean the heat exchanger | No | Requires a certified HVAC professional. |

Keep your lab running safely and efficiently with KINTEK.

Just as proper maintenance is crucial for your home furnace, reliable equipment is the backbone of any successful laboratory. KINTEK specializes in high-quality lab equipment and consumables, ensuring your research and processes are supported by precision and durability.

Whether you need a new furnace for heat treatment, vacuum systems for specialized processes, or any other lab essential, our experts are here to help you choose the right solution.

Contact KINTEK today to discuss your laboratory needs and discover how our products can enhance your lab's performance and safety.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the temperature sintering of alumina? Unlock Superior Performance with 1500°C to 1700°C

- What are the units for vacuum pressure? Torr, mbar, and Pascal Explained

- How does a precision furnace affect 316LN phase transformation? Control Sigma Phase & Prevent Micro-Cracks

- What is vacuum hardening? Achieve Superior Surface Quality and Hardness

- What is the difference between a vacuum furnace and an inert gas furnace? Choose the Right Heat Treatment Process

- Is brazing environmentally friendly? A Guide to Sustainable, Low-Impact Joining

- What are the different types of carburizing? Choose the Right Process for Your Steel Parts

- What is the impact of a high vacuum environment on the densification of SiC/MoSi2-SiC-Si coatings? | KINTEK