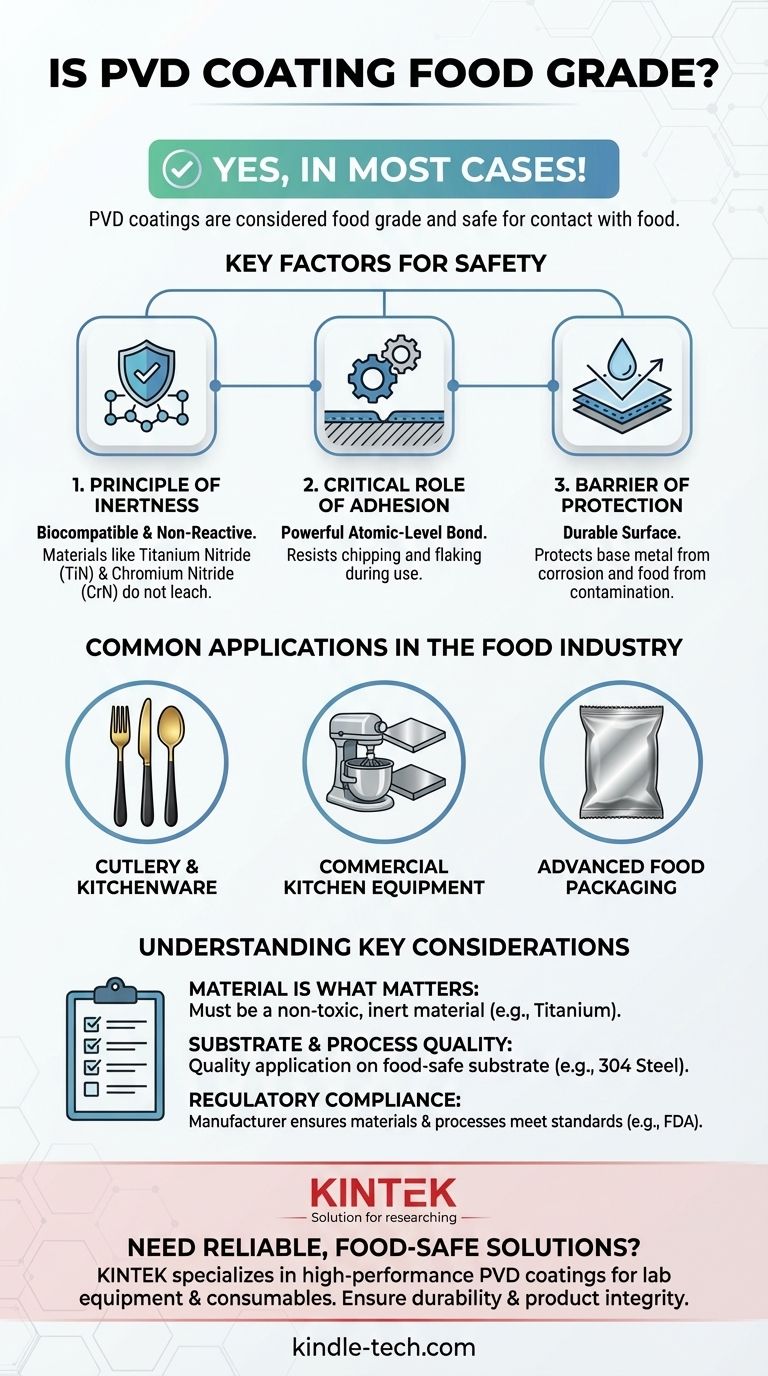

Yes, in most cases, PVD coatings are considered food grade and safe for contact with food. The safety of Physical Vapor Deposition (PVD) coatings stems from two primary factors: the materials used are typically chemically and biologically inert, and the application process creates an extremely strong bond with the underlying material, preventing the coating from flaking off.

The food safety of a PVD-coated product is not determined by the process alone, but by the specific combination of an inert coating material and a high-quality application that ensures durability and prevents any interaction with the food it touches.

What Makes a PVD Coating Food Safe?

The "food grade" status of a PVD coating is a result of its fundamental physical and chemical properties. It’s not just a label, but a functional outcome of the material and the process.

The Principle of Inertness

Most materials used for PVD coatings in food-related applications, such as titanium nitride (TiN) and chromium nitride (CrN), are biocompatible and non-reactive.

This means they do not leach chemicals or metallic ions into food, even when exposed to acidic substances like lemon juice or tomato sauce. They are chemically and biologically inert, so they pass through the body without being absorbed.

The Critical Role of Adhesion

The PVD process forms a powerful, atomic-level bond between the coating and the substrate (the base material, like stainless steel).

This bond is exceptionally strong, meaning the coating is highly resistant to chipping, peeling, or flaking off during normal use. This ensures that particles of the coating do not mix with food.

A Barrier of Protection

A PVD coating acts as a durable barrier. It protects the food from the base metal and protects the product itself from corrosion or wear.

This is especially important for commercial kitchen equipment, where constant use and cleaning could otherwise degrade the surface.

Common Applications in the Food Industry

PVD coatings are not a niche technology; they are widely used in applications where food contact is constant and safety is paramount.

Cutlery and Kitchenware

PVD is frequently used to apply decorative and durable finishes to cutlery, giving it colors like gold, black, or copper. This coating is far more resilient than traditional plating and withstands repeated washing.

Commercial Kitchen Equipment

The exceptional wear resistance of PVD coatings makes them ideal for high-contact parts in food processing machinery and commercial kitchens. This durability ensures a long service life and a consistently safe surface.

Advanced Food Packaging

Many modern food packages, like the metallic lining inside a bag of chips, use a PVD-like process called metallization. This thin layer of aluminum provides a barrier against oxygen and moisture, keeping food fresh without directly contacting it.

Understanding the Key Considerations

While PVD is generally safe, its "food grade" status is conditional. The safety depends entirely on using the right materials and a high-quality process.

The Coating Material Is What Matters

The safety hinges on the specific material being deposited. Using a non-toxic, inert material like titanium is what makes the final product safe. It is the manufacturer's responsibility to select and certify a material that is approved for food contact.

Substrate and Process Quality

A poorly applied coating could potentially fail, compromising safety. The underlying material, or substrate, must also be food-safe. A quality PVD application on a certified food-grade material like 304 stainless steel is the gold standard.

Regulatory Compliance

For any product to be commercially sold as "food safe," the manufacturer must ensure that their specific materials and processes meet regulatory standards, such as those set by the FDA in the United States. This involves rigorous testing for leaching and durability.

How to Verify Food Safety for Your Application

Choosing or specifying a PVD-coated product requires attention to its intended purpose and the supplier's qualifications.

- If your primary focus is designing a new food product: Specify inert coating materials like titanium nitride (TiN) or chromium nitride (CrN) and partner with a PVD supplier who can provide documentation of regulatory compliance.

- If your primary focus is purchasing for a home or business: Buy from reputable manufacturers who explicitly state that their products are food-safe and intended for culinary use.

Ultimately, PVD technology provides a proven method for creating highly durable, non-toxic, and safe surfaces for a wide range of food-related applications.

Summary Table:

| Key Factor | Why It Matters for Food Safety |

|---|---|

| Material Inertness | Coating materials like TiN and CrN are non-reactive and do not leach chemicals into food. |

| Strong Adhesion | The PVD process creates a durable bond, preventing the coating from chipping or flaking. |

| Barrier Protection | The coating protects the base material from corrosion and the food from the substrate. |

| Regulatory Compliance | High-quality applications meet FDA and other food safety standards. |

Need a reliable, food-safe coating solution for your laboratory or food processing equipment?

At KINTEK, we specialize in high-performance PVD coatings for lab equipment and consumables. Our expertise ensures your products meet the highest standards of durability and food safety. Let us help you protect your investment and guarantee product integrity.

Contact our experts today to discuss your specific needs and learn how KINTEK's solutions can benefit your operation.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Is diamond coating worth it? Maximize Component Life and Performance

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application