In short, yes. PVD (Physical Vapor Deposition) gold plating is exceptionally durable and represents a significant upgrade over traditional gold plating methods. It is highly resistant to abrasion, corrosion, and tarnishing, making it a preferred finish for items that see frequent use. The process creates a finish that is fundamentally stronger and more integrated with the base metal.

While no coating is completely indestructible, PVD gold offers a superior level of durability for everyday items. Its strength comes not from thickness, but from a modern application process that molecularly bonds a hard, thin layer of metal to the object's surface.

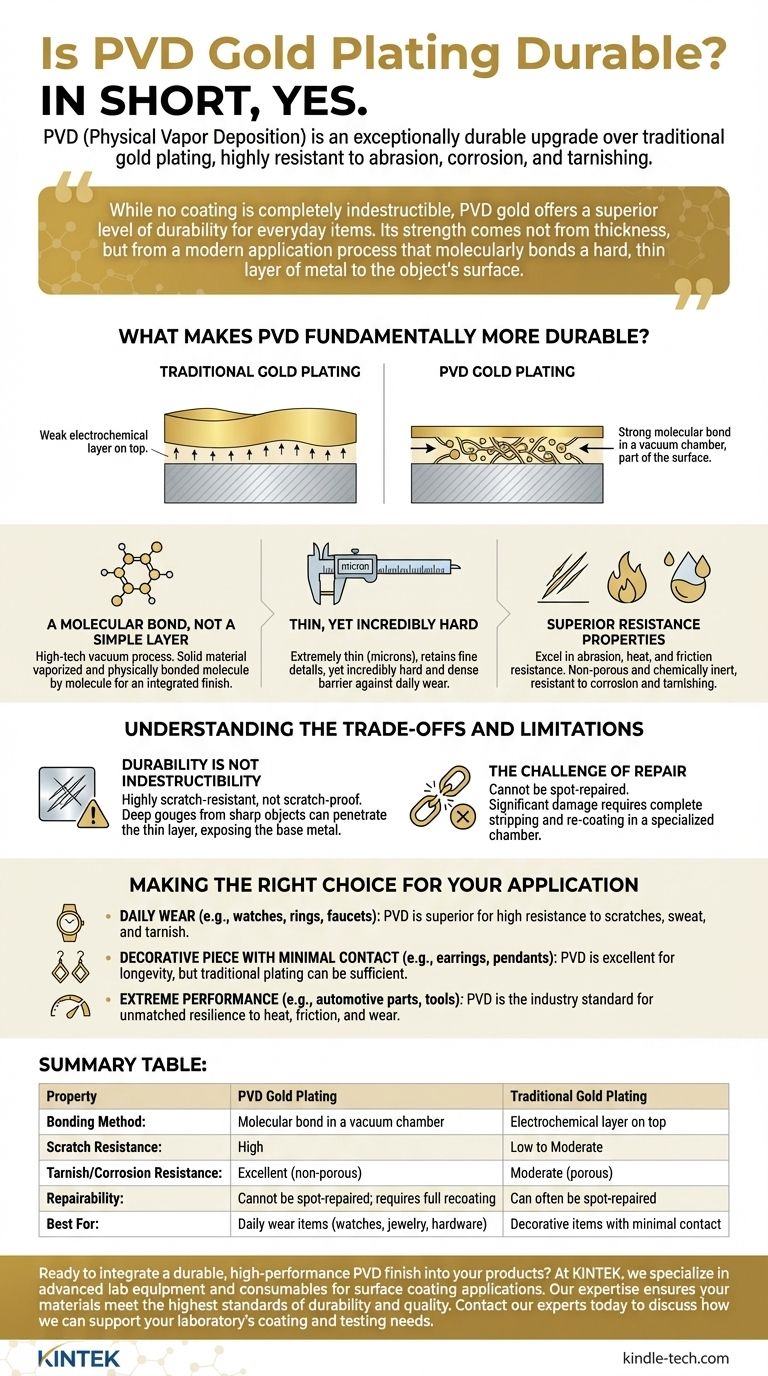

What Makes PVD Fundamentally More Durable?

The durability of PVD isn't just an incremental improvement; it stems from a completely different scientific process compared to traditional electroplating.

A Molecular Bond, Not a Simple Layer

Traditional gold plating uses an electrochemical process to deposit a soft layer of gold onto a surface. This layer sits on top of the base metal and has a relatively weak bond.

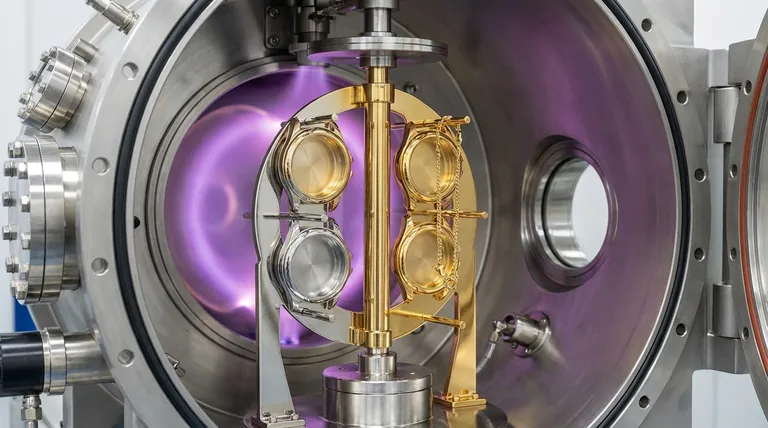

PVD, in contrast, takes place in a high-tech vacuum chamber. A solid material (often a combination of titanium and other elements to create the gold color) is vaporized into plasma and then physically bonded to the substrate, molecule by molecule.

This creates an extremely strong, integrated finish that is part of the surface itself, not just sitting on it.

Thin, Yet Incredibly Hard

PVD coatings are extremely thin, often measured in microns. This allows the product to retain its original shape, texture, and fine details perfectly.

Despite this thinness, the coating is incredibly hard and dense. It provides a tough barrier that is highly resistant to the scratches and scuffs of daily wear.

Superior Resistance Properties

The process results in a finish that excels in multiple areas. PVD coatings exhibit high resistance to abrasion, heat, and friction.

Crucially, the coating is also non-porous and chemically inert, making it highly resistant to the corrosion and tarnishing that can plague traditional plated items when exposed to sweat, chemicals, or the elements.

Understanding the Trade-offs and Limitations

To make an informed decision, you must also understand where PVD has its limits. Objectivity requires acknowledging that no finish is perfect.

Durability Is Not Indestructibility

While highly resistant, a PVD coating can still be damaged. A deep gouge from a sharp or abrasive object can penetrate the thin layer and expose the base metal underneath.

It is best described as highly scratch-resistant, not scratch-proof. Aggressive impacts or grinding against a harder material can compromise the finish.

The Challenge of Repair

This is perhaps the most significant limitation. Unlike some traditional finishes, a damaged PVD coating cannot be spot-repaired.

If the coating is significantly damaged, the entire object would need to be stripped and completely re-coated in a specialized PVD chamber. For most consumer goods, this is not a practical or cost-effective option.

The Color Is the Coating

It is important to remember that the "gold" is a very thin surface layer. If you manage to scratch through the PVD coating, the color of the underlying base metal (often stainless steel or titanium) will show through.

Making the Right Choice for Your Application

Your decision should be based on the intended use of the item and your performance expectations.

- If your primary focus is daily wear (e.g., watches, rings, faucets): PVD is the superior choice for its high resistance to scratches, sweat, and tarnish.

- If your primary focus is a decorative piece with minimal contact (e.g., earrings, pendants): While PVD remains an excellent choice for longevity, traditional plating can be sufficient for items not subject to constant wear.

- If your primary focus is extreme performance (e.g., automotive parts, tools): PVD is the industry standard precisely because of its unmatched resilience to heat, friction, and wear.

By understanding its process and properties, you can confidently choose PVD for a finish that is both beautiful and built to withstand the rigors of its intended use.

Summary Table:

| Property | PVD Gold Plating | Traditional Gold Plating |

|---|---|---|

| Bonding Method | Molecular bond in a vacuum chamber | Electrochemical layer on top |

| Scratch Resistance | High | Low to Moderate |

| Tarnish/Corrosion Resistance | Excellent (non-porous) | Moderate (porous) |

| Repairability | Cannot be spot-repaired; requires full recoating | Can often be spot-repaired |

| Best For | Daily wear items (watches, jewelry, hardware) | Decorative items with minimal contact |

Ready to integrate a durable, high-performance PVD finish into your products? At KINTEK, we specialize in advanced lab equipment and consumables for surface coating applications. Our expertise ensures your materials meet the highest standards of durability and quality. Contact our experts today to discuss how we can support your laboratory's coating and testing needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films