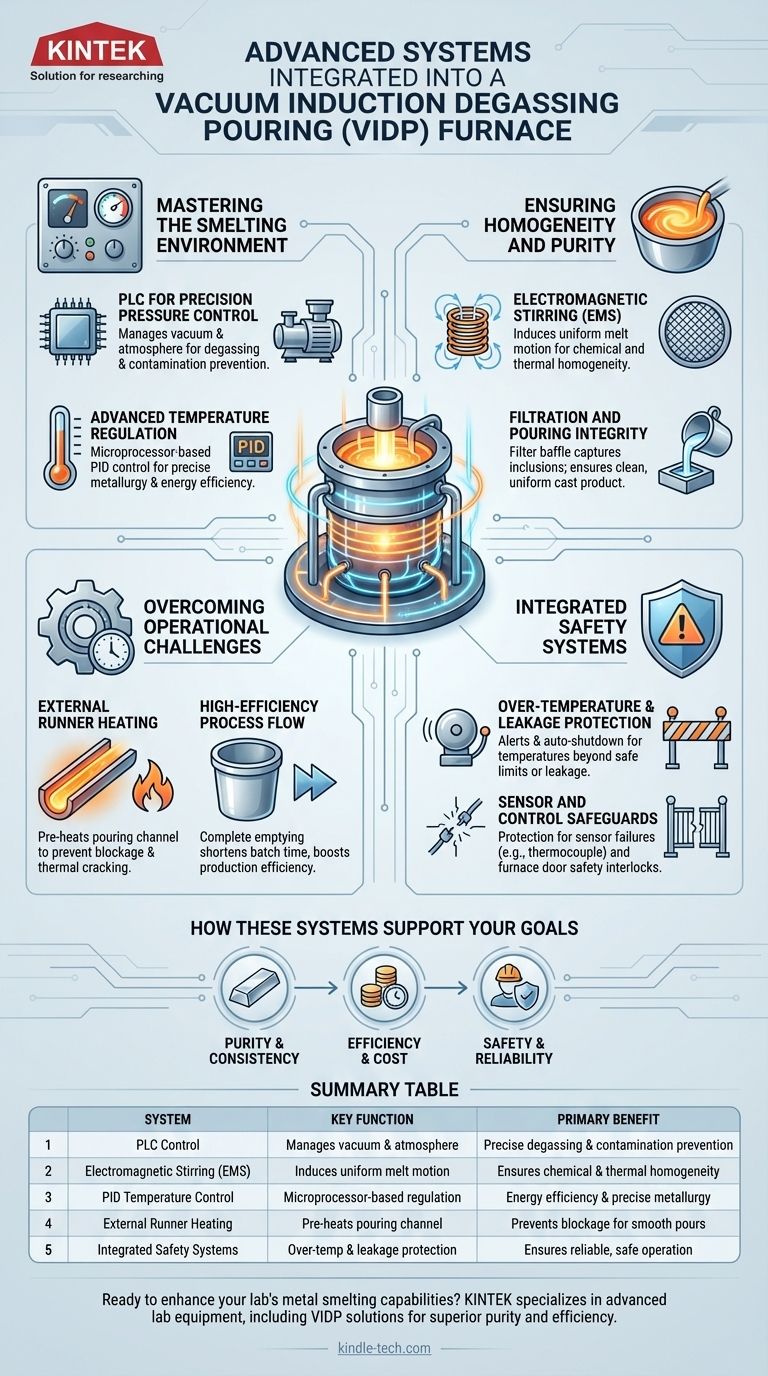

To enhance the smelting process, a Vacuum Induction Degassing Pouring (VIDP) furnace integrates a suite of advanced systems designed for precise control, material purity, and operational safety. Key components include a PLC for ideal pressure management, an electromagnetic stirring system for homogeneity, external runner heating to ensure smooth pouring, and advanced temperature controls for efficiency and precision.

A modern VIDP furnace is not merely a vessel for melting metal in a vacuum; it is a highly integrated system where each component works in concert to control the entire metallurgical process, from refining the melt to pouring the final product, ensuring exceptional quality and consistency.

Mastering the Smelting Environment

The core challenge in producing high-purity metals is maintaining absolute control over the atmospheric and thermal conditions. VIDP furnaces employ sophisticated systems to manage this environment with high precision.

PLC for Precision Pressure Control

A Programmable Logic Controller (PLC) serves as the brain for the furnace's atmosphere. It precisely manages vacuum levels for degassing or introduces a protective atmosphere during pouring.

This control is critical for removing dissolved gases like oxygen and hydrogen from the melt and preventing re-contamination from the ambient air during the crucial pouring stage.

Advanced Temperature Regulation

Modern furnaces use microprocessor-based PID (Proportional-Integral-Derivative) controllers for temperature management. Many include a self-tuning capability to prevent the temperature from overshooting the set point.

This high-precision regulation allows for effective adjustments to the metal's chemical composition and microstructure while simultaneously reducing energy consumption and shortening the overall smelting time.

Ensuring Homogeneity and Purity

Creating a uniform alloy and removing non-metallic inclusions are essential for high-performance materials. Specialized systems address these needs directly within the furnace.

Electromagnetic Stirring (EMS)

An electromagnetic stirring system generates a magnetic field that induces a stable, consistent stirring motion within the entire molten pool.

This ensures that any added alloying elements dissolve uniformly from top to bottom. It also maintains a nearly constant temperature throughout the melt, preventing localized hot or cold spots and promoting chemical homogeneity.

Filtration and Pouring Integrity

To further enhance metal purity, measures like adding a filter baffle can be implemented within the pouring system.

This simple but effective component helps alleviate the turbulence of the molten steel and captures non-metallic inclusions before they enter the final mold, directly improving the cleanliness of the cast product.

Overcoming Operational Challenges

Efficiency and reliability are just as important as purity. VIDP systems are designed to prevent common process failures and maximize production throughput.

External Runner Heating

To prevent initial pouring blockage and thermal cracking, the runner (the channel through which molten metal flows) is heated by an external system.

This pre-heating ensures the runner is at an optimal temperature, preventing the liquid metal from freezing prematurely upon contact and ensuring a smooth, uninterrupted pour.

High-Efficiency Process Flow

The furnace design allows for the crucible to be completely emptied after smelting. This ensures a clean separation between the refined metal and any impurities.

Furthermore, this clean-out capability shortens the preparation time for the next batch, leading to significant cost savings and boosting overall production efficiency.

Integrated Safety Systems

The high-power and high-temperature nature of induction smelting demands robust safety protocols. These are not optional add-ons but are fundamental to the furnace's design.

Over-Temperature and Leakage Protection

VIDP furnaces are equipped with electronic components that provide leakage protection for safe operation.

An over-temperature alarm system will send an alert and can automatically trigger a protection action, such as shutting off power, if temperatures exceed safe limits. This allows for reliable and sometimes unattended operation.

Sensor and Control Safeguards

Further protection is provided for events like a broken thermocouple, which could otherwise lead to a dangerous loss of temperature control.

Additional safety options can include an automatic power-off function that activates when the furnace door is opened, providing an essential layer of protection for operators.

How These Systems Support Your Goals

The integration of these systems allows you to tailor the furnace's operation to meet specific production objectives.

- If your primary focus is material purity and consistency: The combination of PLC-controlled vacuum, electromagnetic stirring, and integrated filtration systems is non-negotiable.

- If your primary focus is production efficiency and cost: The advanced PID temperature control, rapid batch cycling, and high degree of automation are the most critical features.

- If your primary focus is operational safety and reliability: Comprehensive safety interlocks, including over-temperature alarms and leakage protection, are essential for protecting both personnel and the equipment.

Ultimately, a VIDP furnace's advanced systems work in concert to transform a simple melting process into a highly controlled and repeatable manufacturing operation.

Summary Table:

| System | Key Function | Primary Benefit |

|---|---|---|

| PLC Control | Manages vacuum & atmosphere | Precise degassing and contamination prevention |

| Electromagnetic Stirring (EMS) | Induces uniform melt motion | Ensures chemical and thermal homogeneity |

| PID Temperature Control | Microprocessor-based regulation | Energy efficiency and precise metallurgy |

| External Runner Heating | Pre-heats pouring channel | Prevents blockage for smooth, uninterrupted pours |

| Integrated Safety Systems | Over-temperature & leakage protection | Ensures reliable, safe operation |

Ready to enhance your lab's metal smelting capabilities? KINTEK specializes in advanced lab equipment, including vacuum induction furnaces designed for superior purity and efficiency. Our VIDP solutions integrate the precise control and safety features your laboratory needs. Contact us today to discuss how we can support your specific metallurgical goals!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How does induction furnace operate? Master the Science of Efficient, Clean Metal Melting

- What is the output of an induction furnace? High-Purity, Homogenous Molten Metal for Precision Alloys

- What is needed for induction heating? Build Your Efficient, Non-Contact Heating System

- How does a Dual-frequency Induction Heating Machine function? Optimize U71Mn Rail Joint Normalizing for Durability

- Do induction furnaces work on AC or DC? Unlocking the Power of Alternating Current

- What is sintering in induction furnace? Mastering the Thermal Process for Durable Materials

- How can the total required kilowatt-hours (kWh) for a melting process be calculated? Master Your Energy Estimation

- What is the difference between resistance furnace and induction furnace? Choose the Right Heating Method for Your Lab