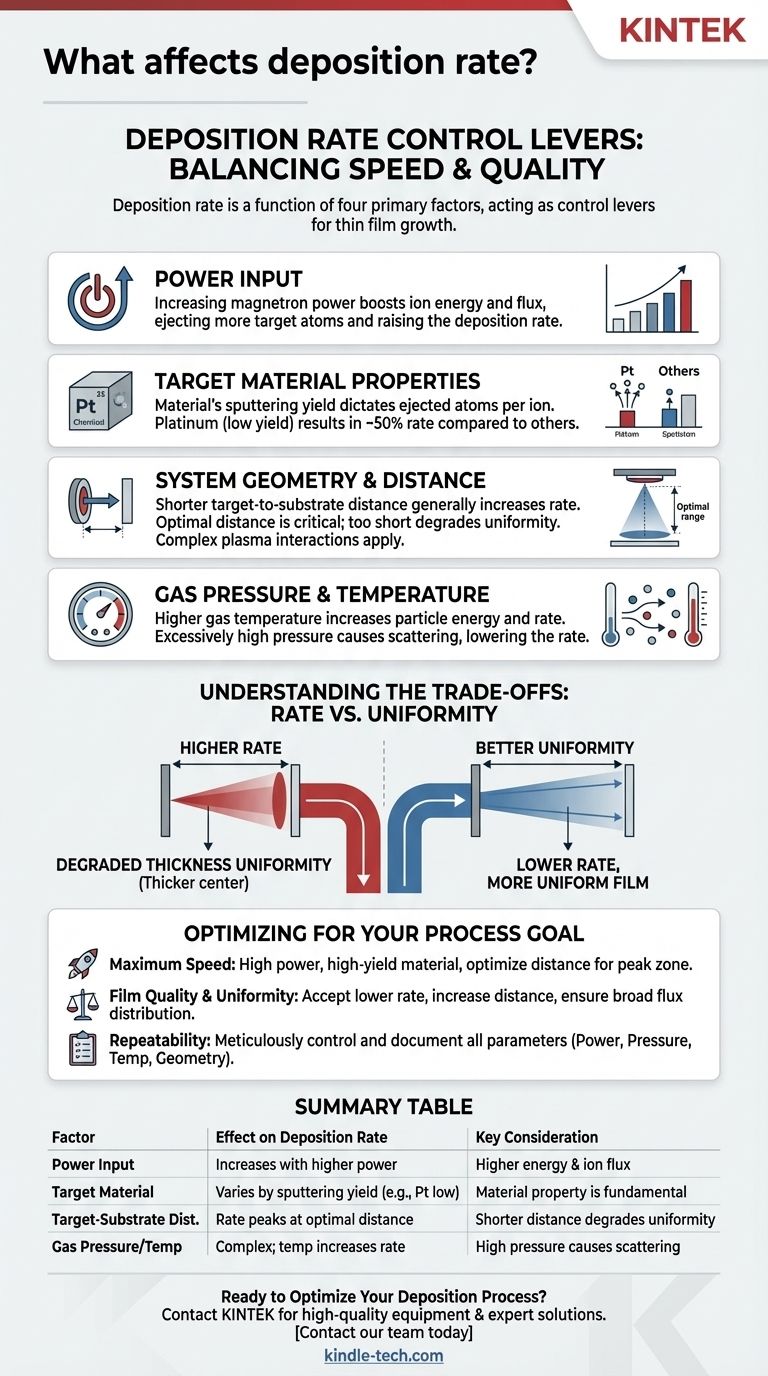

At its core, deposition rate is a function of four primary factors: the power applied to the system, the specific material of the target, the physical geometry between the target and the substrate, and the gas environment (pressure and temperature). Each of these variables acts as a control lever, directly influencing the speed at which a thin film is grown.

The central challenge in controlling deposition rate is not just about maximizing speed, but about balancing the generation of vapor from the source material with its efficient and uniform transport to the substrate. Each parameter adjustment comes with a critical trade-off, most often between deposition speed and film quality.

The Core Levers of Deposition Rate

To effectively control your process, you must understand how each independent variable impacts the final outcome. These factors work in concert, not in isolation.

Power Input

Increasing the magnetron power directly increases the energy and flux of ions bombarding the target material.

This more aggressive bombardment ejects a greater number of target atoms per unit of time, which in turn increases the number of atoms arriving at the substrate, thus raising the deposition rate.

Target Material Properties

The type of material being deposited is a fundamental factor. Different materials have a different sputtering yield, which is the number of atoms ejected for each incident ion.

For example, a platinum target has a lower sputtering yield compared to many other common metals. As a result, it will produce approximately half the deposition rate under otherwise identical conditions.

System Geometry and Distance

The physical spacing within the deposition chamber is critical. Generally, a shorter target-to-substrate distance increases the deposition rate because fewer sputtered atoms are lost to chamber walls.

However, the relationship is not perfectly linear. The rate often reaches a maximum at an optimal distance (for example, around 7mm above the electrode in some systems) before potentially decreasing again. This is due to complex interactions within the plasma sheath near the substrate.

Gas Pressure and Temperature

The environment inside the chamber plays a key role. Increasing the gas temperature can increase particle energy and contribute to a higher deposition rate.

Conversely, gas pressure has a more complex effect. While some pressure is necessary to sustain the plasma, excessively high pressure reduces the mean free path of sputtered atoms, causing them to scatter more, which can lower the rate of deposition onto the substrate.

Understanding the Trade-offs: Rate vs. Uniformity

Achieving the highest possible deposition rate often comes at the expense of other critical film properties, particularly uniformity.

The Distance Dilemma

While decreasing the target-substrate distance boosts the rate, it almost always degrades thickness uniformity.

A shorter distance creates a more concentrated, cone-like deposition flux, making the film thicker in the center and thinner at the edges.

The Erosion Zone Effect

The size of the erosion zone on the target—the area from which material is actively sputtered—is a primary driver of the deposition distribution.

A smaller, more focused erosion zone can lead to a high rate at the center but results in poor film uniformity across the substrate.

Optimizing for Your Process Goal

Your ideal settings will depend entirely on what you prioritize for your specific application.

- If your primary focus is maximum speed: Utilize high power, select a target material with a high sputtering yield, and carefully optimize the target-substrate distance to find the peak deposition zone.

- If your primary focus is film quality and uniformity: Accept a lower rate by increasing the target-substrate distance and ensuring your system geometry promotes a broad, even distribution of material flux.

- If your primary focus is repeatability: Meticulously control and document all parameters—power, pressure, temperature, and geometry—as their interplay defines the final outcome.

By understanding these principles, you gain direct control over the balance between deposition efficiency and final film quality.

Summary Table:

| Factor | Effect on Deposition Rate | Key Consideration |

|---|---|---|

| Power Input | Increases rate with higher power | Higher energy and flux of ions |

| Target Material | Varies by sputtering yield (e.g., Pt is low) | Material property is fundamental |

| Target-Substrate Distance | Rate peaks at an optimal distance | Shorter distance can degrade uniformity |

| Gas Pressure/Temperature | Complex effect; temperature can increase rate | High pressure can cause scattering |

Ready to Optimize Your Deposition Process?

Understanding the trade-offs between deposition rate and film quality is crucial for your lab's success. KINTEK specializes in providing high-quality lab equipment and consumables for precise thin-film deposition. Whether your priority is maximum speed, superior uniformity, or repeatable results, our experts can help you select the right sputtering targets and configure your system for optimal performance.

Contact our team today to discuss your specific application and discover how KINTEK's solutions can enhance your research and development.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication