At its core, brazing is a versatile metal-joining process used across a vast range of industries, from everyday consumer goods to mission-critical aerospace components. Its applications include creating leak-proof joints in HVAC systems, assembling complex automotive engine parts, and fabricating high-performance components for gas turbines and medical devices.

Brazing is not chosen for what it is, but for what it allows. It is the go-to process for creating strong, permanent, and often leak-proof joints in complex assemblies, especially when joining dissimilar metals or when the base materials cannot withstand the high heat of welding.

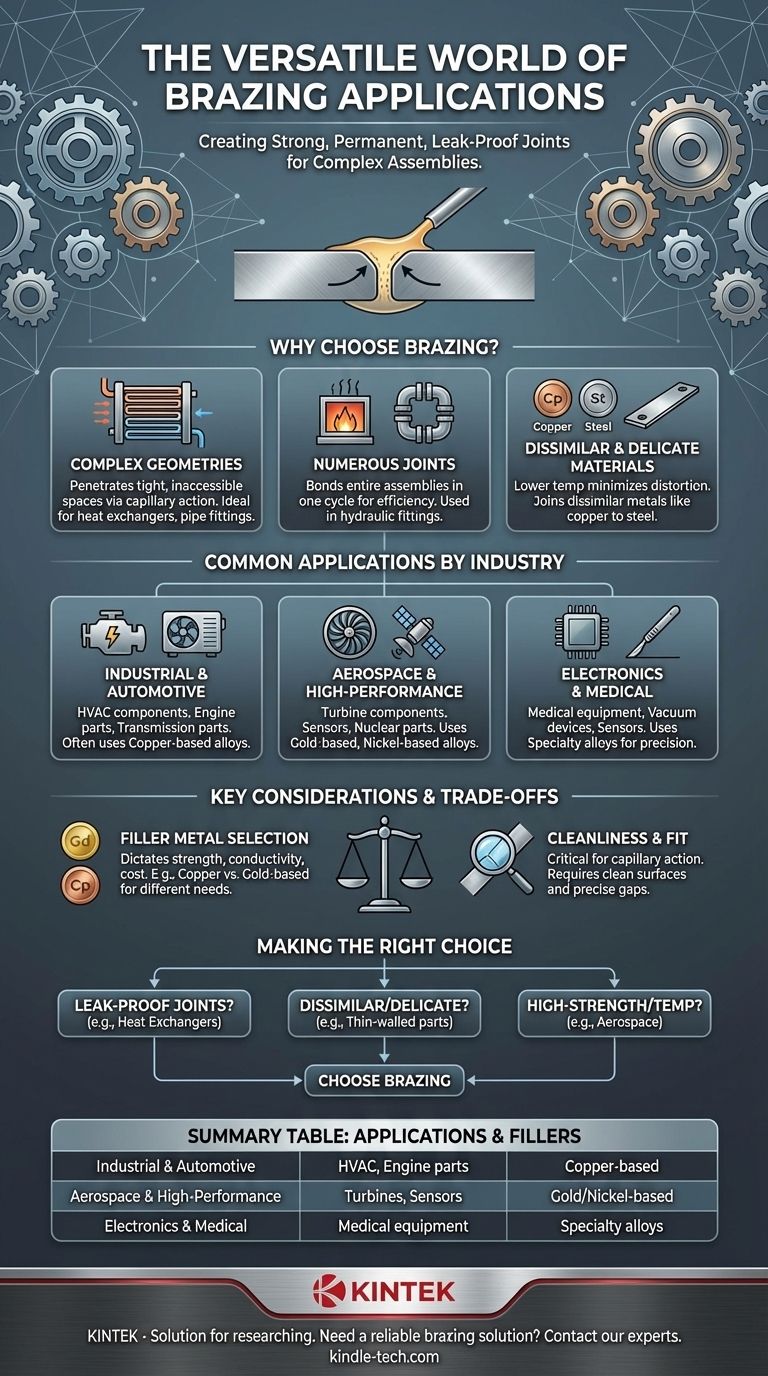

When Brazing is the Ideal Process

Understanding why brazing is selected reveals its fundamental advantages over other joining methods. The decision to braze is typically driven by the geometry of the part, the materials involved, and the performance requirements of the final assembly.

For Complex Geometries and Inaccessible Joints

Brazing excels where other methods fail due to complexity. The filler metal is drawn into the joint via capillary action, allowing it to penetrate tight spaces and create strong bonds in areas that are not directly accessible for welding.

This makes it ideal for components like heat exchangers and intricate pipe fittings, where joints may be hidden or located deep within the assembly.

For Assemblies with Numerous Joints

Processes like furnace brazing allow an entire assembly with dozens or even hundreds of joints to be bonded in a single heating cycle. This is a significant advantage in efficiency and consistency.

This capability is leveraged in manufacturing hydraulic fittings, machined assemblies, and other components where multiple connections must be made simultaneously.

For Joining Dissimilar or Delicate Materials

Brazing occurs at a temperature below the melting point of the base materials being joined. This lower-temperature process minimizes the risk of thermal distortion or damage, which is critical for delicate or thin-walled parts.

It also enables the robust joining of dissimilar metals, such as copper to steel, which is often difficult or impossible to achieve with fusion welding.

Common Applications by Industry

Brazing's unique capabilities make it a cornerstone manufacturing process in several key sectors.

Industrial and Automotive

In these high-volume sectors, brazing is valued for its reliability and suitability for automation. It creates strong, permanent, and leak-proof seals essential for fluid and gas management.

Common examples include HVAC components, automotive engine and transmission parts, and micro-channel heat exchangers. Copper-based filler metals are frequently used here for their excellent thermal conductivity and strength.

Aerospace and High-Performance Engineering

For aerospace, defense, and energy applications, component failure is not an option. Brazing is used to create joints that can withstand extreme temperatures, pressures, and vibrations.

Applications range from industrial gas turbine components and aerospace sensors to nuclear and petrochemical parts. High-performance fillers, including gold-based alloys, are used for critical components like aviation engine parts due to their superior strength and corrosion resistance.

Electronics and Medical Devices

In high-technology fields, brazing provides the precision needed for miniature and sensitive components. The process creates clean joints with excellent electrical and thermal conductivity without damaging delicate electronics.

This is critical for fabricating medical and scientific equipment, electronic vacuum devices, and specialized sensors where reliability and performance are paramount.

Key Considerations and Trade-offs

While powerful, brazing is not a universal solution. Success depends on understanding its specific requirements.

The Critical Role of Filler Metal

The choice of filler metal dictates the final properties of the joint, including its strength, conductivity, and corrosion resistance.

A copper-based alloy might be perfect for a cost-effective HVAC assembly, but a gold-based alloy may be required for a high-reliability aerospace component, creating a trade-off between cost and performance.

The Requirement for Cleanliness and Fit

Brazing relies on capillary action, which requires the gap between the two joining surfaces to be very small and consistent.

Furthermore, the surfaces must be exceptionally clean and free of oxides for the filler metal to wet and flow properly. This often requires careful joint design and a thorough pre-cleaning process, adding steps to the manufacturing workflow.

Making the Right Choice for Your Application

To determine if brazing is the correct process, evaluate your primary design goal.

- If your primary focus is creating leak-proof joints in complex tube assemblies: Brazing is an ideal choice, especially for parts like heat exchangers and hydraulic systems.

- If your primary focus is joining dissimilar metals or delicate, thin-walled parts: The lower process temperature of brazing makes it superior to welding, preventing damage and distortion.

- If your primary focus is high-strength, temperature-resistant joints for critical components: Brazing with specialized filler alloys is a proven method used in the most demanding industries like aerospace and defense.

Ultimately, choosing to braze is a decision to prioritize joint integrity and design flexibility for complex engineering challenges.

Summary Table:

| Industry | Key Applications | Common Filler Metals |

|---|---|---|

| Industrial & Automotive | HVAC components, engine parts, heat exchangers | Copper-based alloys |

| Aerospace & High-Performance | Turbine components, sensors, nuclear parts | Gold-based, nickel-based alloys |

| Electronics & Medical | Medical equipment, vacuum devices, sensors | Specialty alloys for conductivity |

Need a reliable brazing solution for your lab equipment? KINTEK specializes in providing high-performance lab equipment and consumables, ensuring your brazing processes deliver strong, leak-proof joints for complex assemblies. Contact our experts today to discuss how we can support your specific application needs and enhance your manufacturing capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the process of vacuum brazing? Achieve High-Purity, Strong Metal Joining

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing