At its core, a hydraulic press offers a unique combination of immense force generation and precise control in a remarkably simple and efficient design. Its primary benefits stem from its ability to multiply a small amount of applied force into a massive output, all while maintaining a compact footprint, lower initial cost, and built-in safety features compared to many mechanical alternatives.

The true advantage of a hydraulic press isn't just its raw power; it's the elegant simplicity of its operation. By leveraging the principles of fluid dynamics, it delivers unparalleled force multiplication and control with fewer moving parts, making it a more adaptable and cost-effective solution for a vast range of applications.

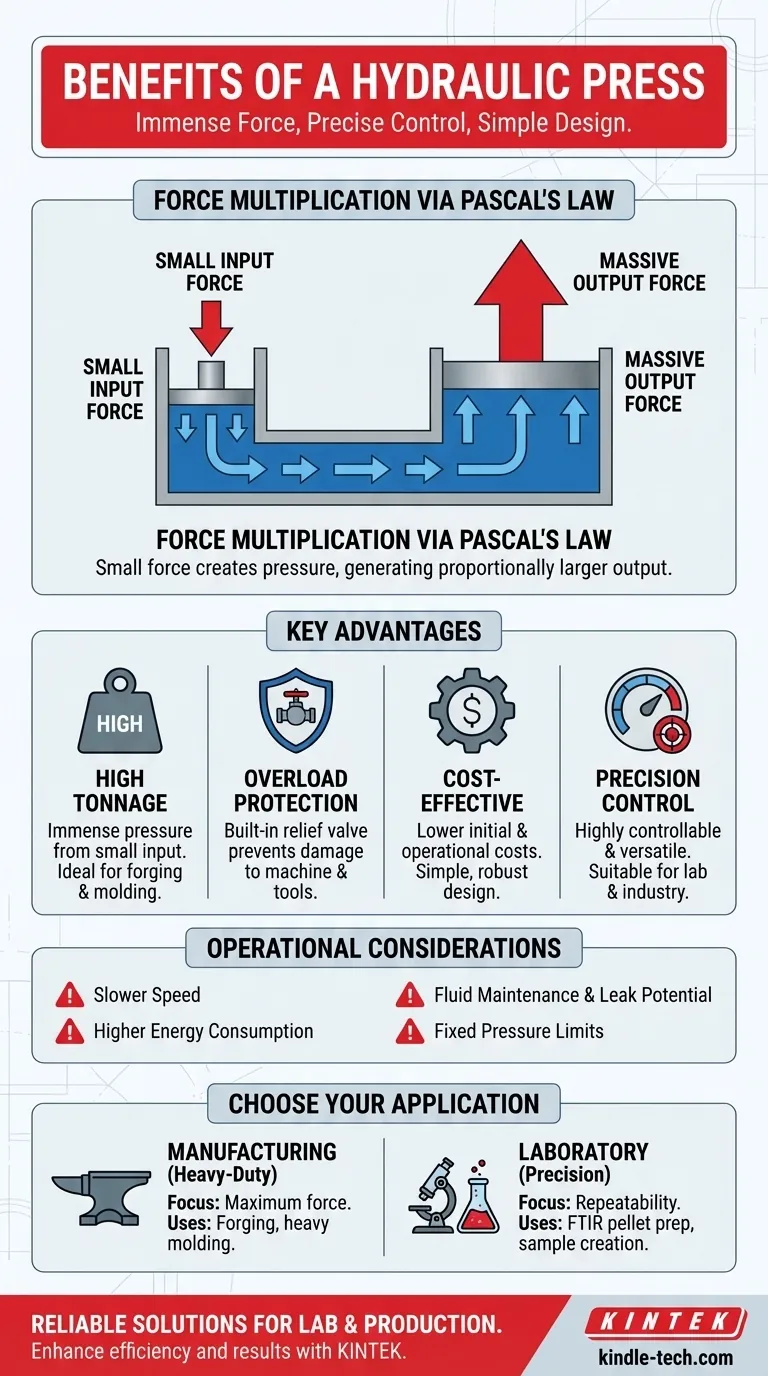

The Principle of Force Multiplication

The entire value proposition of a hydraulic press is built on a fundamental law of physics. Understanding this principle is key to appreciating its design and operational advantages.

How Pascal's Law Enables Power

A hydraulic press operates on Pascal's law, which states that pressure applied to a confined, incompressible fluid is transmitted equally throughout that fluid.

The machine applies a small force to a small piston, creating pressure in the hydraulic fluid. This same pressure then acts on a much larger piston, generating a proportionally larger output force. This is the essence of force multiplication.

The Impact on Machine Design

This principle allows for a very simple and robust design. A hydraulic press requires far fewer moving parts than a mechanical press of comparable power.

This simplicity leads directly to benefits like a smaller physical footprint, lighter overall weight, and increased reliability over its operational life.

Key Operational and Economic Advantages

The physical principles of a hydraulic press translate directly into tangible benefits for the operator, from safety to cost savings.

Generating High Tonnage with Ease

The most cited benefit is the ability to generate immense pressure and tonnage from a relatively small motor or manual input. This makes it ideal for tasks requiring significant force, such as forging, molding, and sample preparation.

Built-in Overload Protection

Unlike mechanical presses, hydraulic systems have built-in overload protection. The maximum pressure is determined by a relief valve.

If the operational force exceeds this preset limit, the valve opens, preventing damage to the machine and protecting the tools or molds. This feature significantly extends the lifespan of expensive tooling.

Cost-Effectiveness and Efficiency

Hydraulic presses often have a lower initial purchase price and ongoing production costs. Their simple design reduces manufacturing complexity and the number of components that can fail.

This also translates to lower mold costs and the conservation of materials during production processes.

Adaptability and Precision Control

The output force of a hydraulic press is highly controllable. This makes it extremely versatile, suitable for both heavy industrial work and delicate laboratory applications.

For example, in labs, they are used to create highly consistent and uniform pellets for FTIR spectroscopy, where repeatability is critical for reliable test results.

Understanding the Trade-offs and Limitations

To make an informed decision, it is crucial to recognize that the benefits of a hydraulic press come with specific operational trade-offs.

Speed and Energy Consumption

Hydraulic presses are generally slower than their mechanical counterparts. The time it takes to build and release fluid pressure limits the cycle speed.

They can also have high energy consumption, as the pump often needs to run continuously to maintain pressure, even when the press is not actively moving.

Maintenance and Fluid Management

The reliance on hydraulic fluid introduces specific maintenance needs. There is always a potential for fluid leakage, which can be a safety and environmental concern.

Furthermore, some hydraulic fluids can be flammable, and the system requires regular checks to ensure fluid cleanliness and proper function.

Fixed Pressure Limits

While the force is immense, it is regulated and cannot exceed the system's designed pressure limit. The relief valve that provides overload protection also creates a hard ceiling on the machine's maximum output.

Making the Right Choice for Your Application

Selecting the right press depends entirely on balancing its inherent advantages against the demands of your specific task.

- If your primary focus is maximum force and heavy-duty manufacturing: The high tonnage, simple design, and built-in overload protection make the hydraulic press a superior choice.

- If your primary focus is precision and repeatable lab work: The consistent and controllable pressure is ideal for creating uniform samples for analysis.

- If your primary focus is cost-efficiency and a compact footprint: The lower initial cost and space-saving design provide significant value, especially compared to mechanical presses of similar power.

Ultimately, the hydraulic press excels by translating a simple physical principle into a powerful, adaptable, and highly effective tool for a wide range of tasks.

Summary Table:

| Benefit | Description |

|---|---|

| Force Multiplication | Generates immense tonnage from a small input force using Pascal's Law. |

| Precision Control | Offers highly controllable and repeatable pressure for delicate tasks. |

| Overload Protection | Built-in relief valve prevents damage to machine and tooling. |

| Cost-Effectiveness | Lower initial cost, simpler design, and reduced maintenance vs. mechanical presses. |

| Versatility | Suitable for heavy industrial work (forging) and precise lab applications (FTIR pellet preparation). |

| Compact Design | Smaller footprint and lighter weight due to fewer moving parts. |

Need a Reliable Hydraulic Press for Your Lab or Production Line?

KINTEK specializes in high-quality lab equipment and consumables, including hydraulic presses designed for precision and durability. Whether you're in manufacturing requiring high tonnage or a laboratory needing consistent sample preparation for FTIR spectroscopy, our presses deliver the force, control, and reliability you need.

Let us help you enhance your efficiency and results.

Contact KINTEK today to discuss your specific requirements and find the perfect hydraulic press solution for your application!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- How much does a hydraulic press weight? From 20kg Benchtop to Multi-Ton Industrial Giants

- What is the purpose of using a uniaxial hydraulic press to prepare green bodies for microwave-assisted synthesis?

- What role does a laboratory hydraulic press play in testing solid-state electrolytes? Optimize Your Material Density

- What is the function of a laboratory hydraulic press in solid-state battery assembly? Achieve Superior Densification

- How is a hydraulic press used to verify contaminated electrolyte solidification? Ensure 17-26 MPa Safety Compliance

- What are the safety hazards of hydraulic presses? Mitigate Crush, Injection, and Ejection Risks

- What is the difference between rolling and bending? Choose the Right Metal Forming Process

- What is the function of a laboratory hydraulic press in the assembly of sulfide-based all-solid-state battery test cells?