At its core, a filter press is a tool designed for solid-liquid separation. This process is fundamental across a vast range of applications, from massive industrial operations that dewater tons of material to precise laboratory instruments used for creating highly specific analytical samples. The core function remains the same: to remove liquid from a slurry, leaving a compressed solid "cake."

While the term "filter press" describes a single mechanical principle, its application splits into two distinct worlds: large-scale industrial dewatering for waste reduction and resource recovery, and small-scale laboratory preparation for analysis and research.

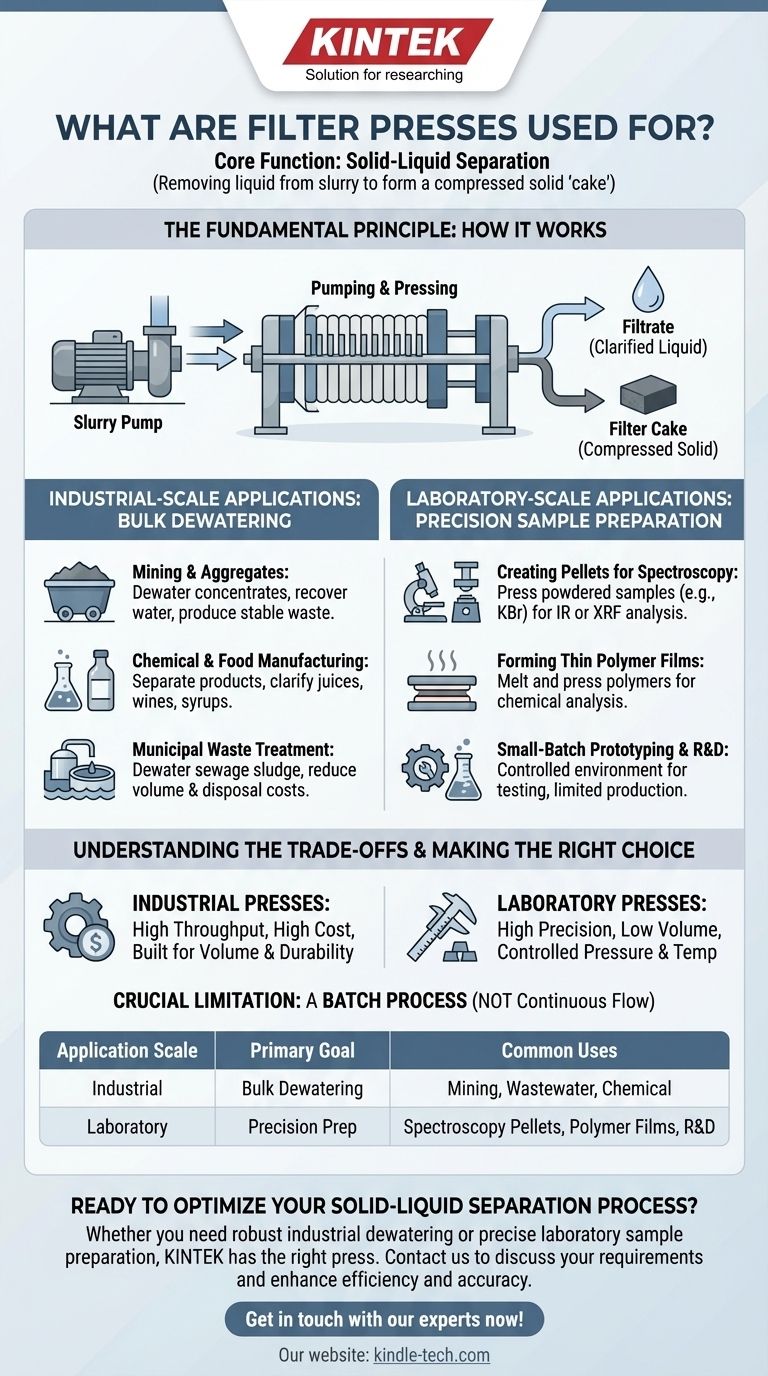

The Fundamental Principle: How a Filter Press Works

A filter press operates on a straightforward principle of pressure filtration. Understanding this core mechanism is key to seeing its value in different contexts.

Pumping and Pressing

A slurry (a mixture of solids and liquids) is pumped into a series of chambers lined with filter cloths. As pressure builds, the liquid is forced through the cloth, while the solids are trapped inside, forming a dense cake.

The Two Products

The process yields two distinct outputs: the filtrate (the clarified liquid that has passed through the filter) and the filter cake (the compressed, dewatered solid material left behind). The relative importance of each product depends entirely on the application.

Industrial-Scale Applications: Bulk Dewatering

In heavy industry, the primary goal is typically to process large volumes of material efficiently. Here, the filter press is a workhorse for bulk separation.

Mining and Aggregates

Filter presses are used to dewater mineral concentrates and tailings. This recovers water for reuse in the plant and produces a drier, more stable solid waste product that is easier and safer to handle and transport.

Chemical and Food Manufacturing

In chemical processing, filter presses separate final products from reaction mixtures or remove impurities. In the food industry, they are used to clarify juices, wines, and syrups by removing suspended solids.

Municipal Waste Treatment

Wastewater treatment plants use large filter presses to dewater sewage sludge. This dramatically reduces the volume of the final waste product, significantly lowering disposal and transportation costs.

Laboratory-Scale Applications: Precision Sample Preparation

In a laboratory, the goal shifts from high volume to high precision. The "press" is often used less for filtration and more for compacting materials under pressure for analysis.

Creating Pellets for Spectroscopy

A common lab use is pressing powdered samples, such as a mix of potassium bromide (KBr) and an organic compound, into small, dense pellets. These pellets are ideal for analysis using infrared (IR) or X-ray fluorescence (XRF) spectroscopy.

Forming Thin Polymer Films

Using heated plates (platens), a laboratory press can melt and press polymer materials into thin, uniform films. These films are then easily analyzed for their chemical properties.

Small-Batch Prototyping and R&D

For research, testing new formulations, or lean manufacturing, a small laboratory press provides a controlled environment for cell manufacturing, creating test pills, and running limited production trials without committing to large-scale equipment.

Understanding the Trade-offs

Choosing the right type of press requires understanding its inherent limitations and operational model.

Industrial Presses: High Throughput, High Cost

These machines are built for durability and volume. They represent a significant capital investment and are designed for processing tons of material, making them unsuitable for small, varied tasks.

Laboratory Presses: High Precision, Low Volume

Laboratory presses offer precise control over pressure and temperature but are designed for very small batches. Their capacity is intentionally limited to serve the needs of research, quality control, and testing.

The Key Limitation: A Batch Process

Crucially, a filter press is a batch-process machine. The cycle involves filling, pressing, opening the press, discharging the cake, and preparing for the next batch. It is not a continuous-flow system, which is a critical consideration for process design.

Making the Right Choice for Your Goal

The right tool depends entirely on your objective. Your decision should be guided by the scale and precision your task demands.

- If your primary focus is dewatering large volumes of industrial slurry: You need an industrial-scale filter press built for high throughput, durability, and efficient solids handling.

- If your primary focus is preparing precise solid samples for analytical testing: You require a dedicated laboratory press with features for small-scale, high-pressure pelletizing or film pressing.

- If your primary focus is testing filtration processes or running small production batches: A versatile, manually operated laboratory or pilot-scale filter press offers the necessary control and flexibility for R&D.

Ultimately, understanding the distinction between industrial dewatering and laboratory preparation is the key to selecting the correct equipment for your needs.

Summary Table:

| Application Scale | Primary Goal | Common Uses |

|---|---|---|

| Industrial | Bulk Dewatering | Mining tailings, wastewater sludge, chemical processing |

| Laboratory | Precision Sample Prep | Creating pellets for spectroscopy, forming polymer films, R&D |

Ready to optimize your solid-liquid separation process?

Whether you need robust industrial dewatering or precise laboratory sample preparation, KINTEK has the right press for your application. Our expertise in lab equipment ensures you get a solution tailored to your specific needs in mining, chemical processing, wastewater treatment, or research.

Contact us today to discuss your requirements and let our specialists help you enhance efficiency and accuracy.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.