The fundamental choice between brazing and welding depends on your project's priorities. Brazing excels at joining dissimilar materials and minimizing thermal distortion by using a filler metal below the melting point of the base parts. Welding, in contrast, creates stronger, more heat-resistant joints by fusing the base metals themselves, making it ideal for high-stress structural applications.

The core difference is simple: welding melts and fuses the base metals to form a joint, while brazing uses a filler metal to bond them without melting them. This single distinction dictates every advantage and disadvantage of each process, from material compatibility to final joint strength.

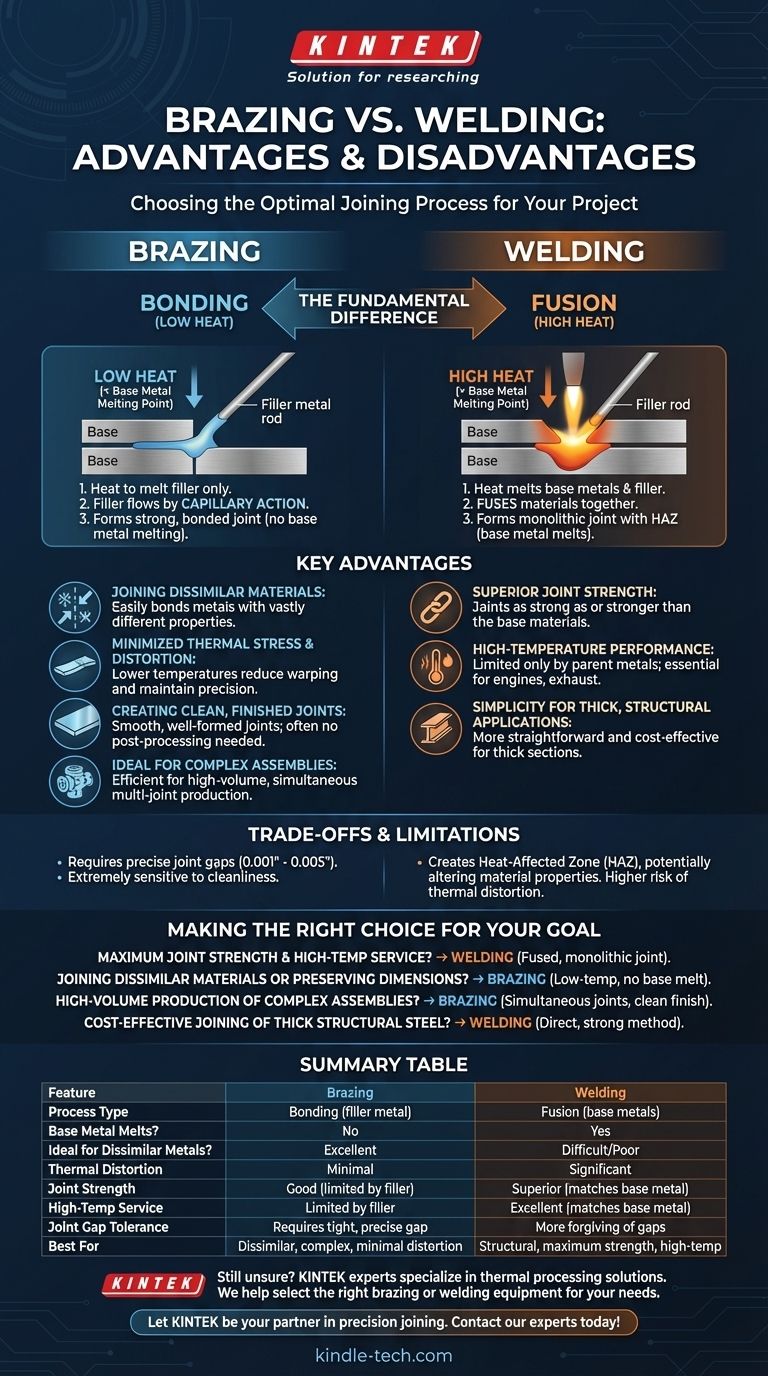

The Fundamental Difference: Fusion vs. Bonding

Before comparing advantages, it's critical to understand the process mechanics. One is a fusion process, the other is a bonding process.

Welding: Creating a Monolithic Joint

Welding uses a high-energy heat source (like an electric arc or flame) to melt the edges of the base materials, often along with a filler material. These molten materials mix, solidify, and form a single, continuous piece of metal.

This creates a metallurgical bond where the joint is effectively a new, cast-metal section of the parent components.

Brazing: Using Capillary Action

Brazing heats the base metals to a temperature high enough to melt a filler alloy, but below the melting point of the parts themselves.

The molten filler is drawn into the tight gap between the components through capillary action. Upon cooling, it solidifies and forms a strong, bonded joint much like a high-strength metallic glue.

Key Advantages of Brazing

Brazing's lower-temperature, non-fusion process provides unique advantages that are critical for certain applications.

Joining Dissimilar Materials

This is perhaps brazing's greatest strength. Because the base metals do not melt, you can easily join materials with vastly different properties and melting points, such as copper to steel or carbide to a tool shank. Welding dissimilar metals is often difficult or impossible.

Minimized Thermal Stress and Distortion

Welding's intense, localized heat creates significant thermal stress, which can cause warping, cracking, and a loss of dimensional accuracy. Brazing uses lower temperatures and often heats the entire assembly more uniformly, drastically reducing the risk of distortion. This is vital for delicate or high-precision components.

Creating Clean, Finished Joints

Brazed joints are typically smooth and well-formed, requiring little to no post-processing or grinding. This is especially true in controlled-atmosphere processes like vacuum brazing, which produce exceptionally clean, high-quality joints free of oxides.

Ideal for Complex and Multi-Joint Assemblies

Brazing lends itself well to automation and high-volume production. An entire assembly with multiple joints can be prepared with filler material and heated in a furnace, allowing all joints to be made simultaneously and efficiently.

Key Advantages of Welding

When strength and temperature resistance are the primary concerns, the fusion process of welding is often the superior choice.

Superior Joint Strength

Because welding fuses the parent metals, the resulting joint can be as strong as, or even stronger than, the base materials themselves. A brazed joint's strength is limited by the strength of the filler alloy, which is typically lower than that of the parent metals.

High-Temperature Performance

A welded joint's performance at high temperatures is limited only by the parent metals. A brazed joint, however, cannot be used at service temperatures that approach the melting point of its filler alloy. This makes welding essential for high-temperature applications like engines and exhaust systems.

Simplicity for Thick, Structural Applications

For joining thick sections of metal, such as in building construction or heavy equipment manufacturing, welding is generally more straightforward and cost-effective. It requires less precise joint preparation and is more forgiving of wider gaps than brazing.

Understanding the Trade-offs and Limitations

Neither process is universally better; the choice is always a matter of balancing competing requirements for your specific application.

Brazing's Dependence on Joint Design

Brazing is critically dependent on a well-designed joint. The gap between the parts must be tight and consistent (typically 0.001" to 0.005") for capillary action to work effectively. Poor fit-up will result in a weak or incomplete joint.

Welding's Impact on Material Properties

The intense heat of welding creates a Heat-Affected Zone (HAZ) in the base metal surrounding the weld. This zone can alter the metal's microstructure, potentially reducing its strength, ductility, or corrosion resistance if not properly controlled. Brazing has a much less significant effect on the base material's properties.

The Critical Role of Cleanliness in Brazing

Brazing requires perfectly clean surfaces. Any oils, dirt, or oxides will prevent the filler metal from "wetting" the base metal and flowing into the joint, leading to failure. While cleanliness is important for welding, brazing is far less forgiving of contamination.

Making the Right Choice for Your Goal

To select the right process, identify your single most important requirement.

- If your primary focus is maximum joint strength and high-temperature service: Welding is the clear choice, as its fused, monolithic joint offers unmatched strength and thermal resistance.

- If your primary focus is joining dissimilar materials or preserving part dimensions: Brazing is superior, as its low-temperature process avoids melting the base metals and minimizes thermal distortion.

- If your primary focus is high-volume production of complex assemblies with a finished look: Brazing, particularly furnace brazing, allows for multiple joints to be made simultaneously with minimal post-processing.

- If your primary focus is cost-effective joining of thick, simple structural steel: Welding provides the necessary strength and is often the most direct and economical method for these applications.

Ultimately, understanding that welding creates a new structure while brazing creates a bond is the key to leveraging the unique strengths of each method for your project.

Summary Table:

| Feature | Brazing | Welding |

|---|---|---|

| Process Type | Bonding (filler metal) | Fusion (base metals) |

| Base Metal Melts? | No | Yes |

| Ideal for Dissimilar Metals? | Excellent | Difficult/Poor |

| Thermal Distortion | Minimal | Significant |

| Joint Strength | Good (limited by filler) | Superior (matches base metal) |

| High-Temp Service | Limited by filler melting point | Excellent (matches base metal) |

| Joint Gap Tolerance | Requires tight, precise gap | More forgiving of gaps |

| Best For | Dissimilar materials, complex assemblies, minimal distortion | Structural applications, maximum strength, high-temp use |

Still unsure which joining process is right for your application?

The experts at KINTEK specialize in providing the ideal thermal processing solutions for your laboratory and manufacturing needs. Whether your project requires the precision of brazing or the strength of welding, we can help you select the right equipment and consumables to ensure a successful outcome.

Let KINTEK be your partner in precision joining. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy