For any industrial process requiring solid-liquid separation, a filter press is a powerful and established technology, but it is not a universal solution. Its primary advantage is the ability to produce an exceptionally dry solid cake and very clear liquid filtrate. However, this high performance comes at the cost of being a batch-process system, which introduces significant operational considerations compared to continuous alternatives.

The core decision of choosing a filter press hinges on a fundamental trade-off: accepting a labor-intensive, discontinuous batch process in exchange for achieving the highest possible level of dewatering and filtrate clarity.

How a Filter Press Achieves Superior Separation

To understand its advantages and disadvantages, you must first understand its fundamental mechanism. A filter press does not use gravity or centrifugal force; it relies on pure pressure.

The Principle of High-Pressure Filtration

A powerful hydraulic system clamps a series of filter plates together, creating a network of sealed chambers. A slurry is then pumped under high pressure into these chambers.

The pressure forces the liquid portion of the slurry (the filtrate) to pass through filter cloths lining the plates, while the solid particles are trapped inside.

The Role of the Filter Cake

As solids accumulate, they form a dense, packed layer known as the filter cake. This cake itself becomes an extremely fine filter medium, trapping even smaller particles and resulting in exceptionally clean filtrate.

The Result: High Solids and Clear Filtrate

The cycle ends when the chambers are full of solids and the liquid flow virtually stops. The result is a filter cake with very low moisture content and a filtrate that is often clear enough for immediate reuse or discharge.

Key Advantages Analyzed

The operational benefits of a filter press are directly tied to its high-pressure, static filtration method.

Unmatched Cake Dryness

This is the single greatest advantage. Filter presses can produce cakes with a solids content ranging from 40% to over 70% by weight, often significantly drier than what centrifuges or belt presses can achieve.

This drastically reduces the cost of cake disposal (less weight and volume) and can be essential if the solids are the valuable end product.

Exceptional Filtrate Clarity

Because the filter cake itself acts as a secondary filter, the resulting filtrate is extremely clear. This is critical for applications where the liquid is the valuable product or where strict environmental regulations require clean water discharge.

Robustness and Reliability

Filter presses are mechanically simple and rugged. They have few high-speed moving parts, making them exceptionally durable and well-suited for processing abrasive or corrosive slurries that would quickly wear down other types of equipment.

Understanding the Trade-offs and Disadvantages

The strengths of a filter press are also the source of its weaknesses. The very nature of its operation creates significant challenges you must consider.

The Batch Process Limitation

A filter press is not a continuous system. It operates in a distinct cycle: fill, press, open, discharge cake, clean, and close. This cycle can take anywhere from 30 minutes to several hours.

This batch nature means lower throughput compared to a continuous system of a similar size. It also requires holding tanks to accumulate slurry while the press is in its discharge and cleaning phase.

Labor and Maintenance Intensity

While modern presses offer automation, they still require significant operator oversight. The filter cloths are a critical wear item and a primary source of maintenance.

Cloths can become "blinded" (clogged), reducing efficiency, or can be torn, requiring a full press shutdown for replacement. Cake discharge, even with automatic plate shifters, can be messy and may require manual intervention to ensure all chambers are clear.

Capital and Installation Footprint

Filter presses are heavy, large, and require a substantial foundation. The initial capital cost, especially for larger, fully automated units with safety features like light curtains, can be considerable.

Is a Filter Press Right for Your Application?

Choosing this technology requires a clear-eyed assessment of your primary goal. Weigh the superior performance against the operational reality.

- If your primary focus is maximum cake dryness and filtrate purity: The filter press is almost always the superior choice, as its performance in this area is difficult to match.

- If your primary focus is high throughput and low-labor automation: A continuous system like a belt press or centrifuge is likely a better fit, provided you can accept a wetter cake.

- If you are processing highly abrasive or chemically aggressive slurries: The robust, low-wear design of a filter press makes it a very strong contender.

- If you have limited labor resources or require a "hands-off" process: Carefully analyze the total cost of ownership, as the operational demands of a filter press can negate its performance benefits.

Understanding this core trade-off between separation performance and process continuity is the key to selecting the right technology for your specific operational goals.

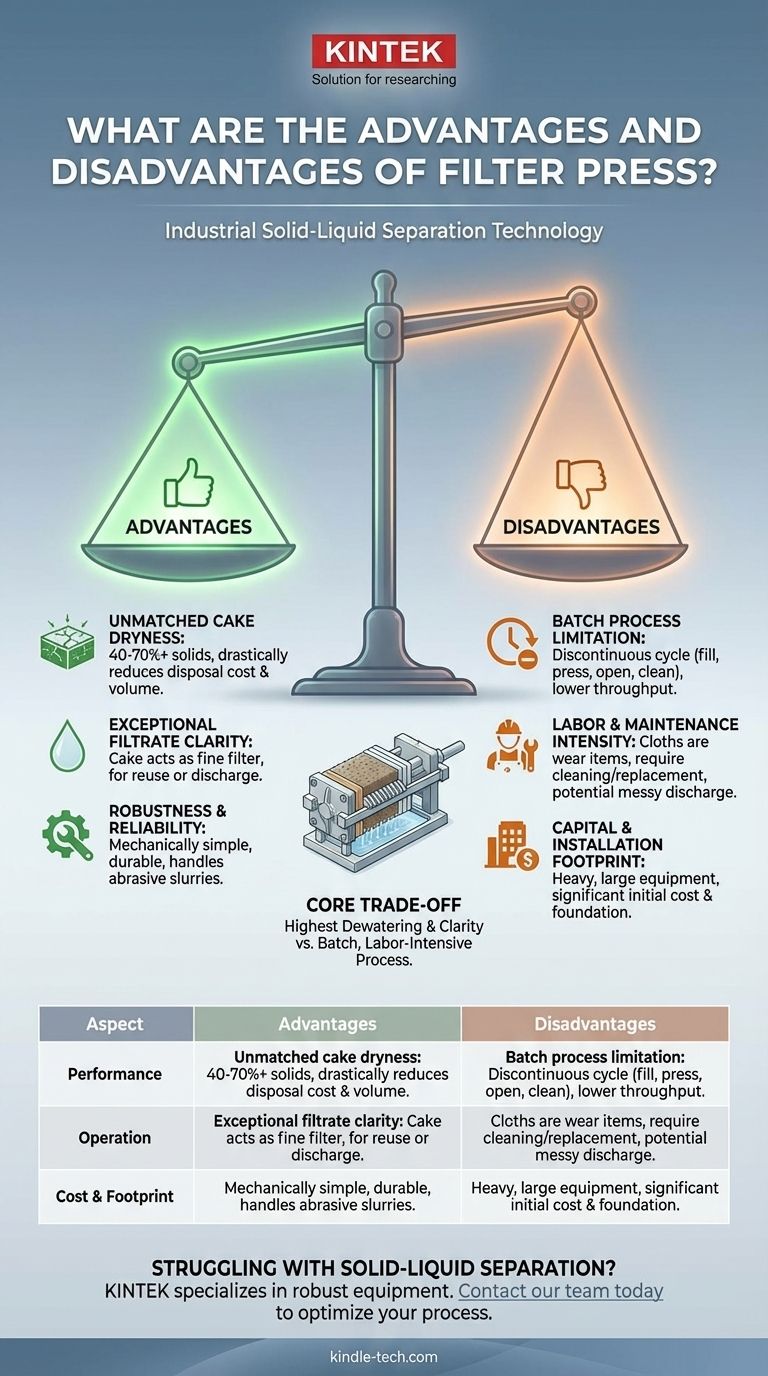

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Performance | Unmatched cake dryness (40-70% solids), exceptional filtrate clarity | Batch process limits throughput compared to continuous systems |

| Operation | Robust, durable, handles abrasive/corrosive slurries well | Labor-intensive maintenance, filter cloths require frequent replacement/cleaning |

| Cost & Footprint | Reduces disposal costs via drier cakes | High initial capital cost, large installation footprint required |

Struggling with solid-liquid separation? KINTEK specializes in robust laboratory and industrial equipment, including filtration solutions. Our experts can help you determine if a filter press is the right choice to achieve your goals of maximum cake dryness and filtrate purity. Contact our team today to discuss your specific application and optimize your process efficiency!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability