The primary advantage of a graphite furnace is its ability to achieve extremely high temperatures with exceptional speed and uniformity. Its unique thermal properties make it highly energy-efficient for demanding applications, far surpassing what is possible with most metallic furnaces.

A graphite furnace offers unparalleled performance for high-temperature processes, delivering rapid heating and excellent uniformity. However, this capability is balanced by the critical risk of carbon contamination and higher initial costs, making it a specialized tool rather than a universal solution.

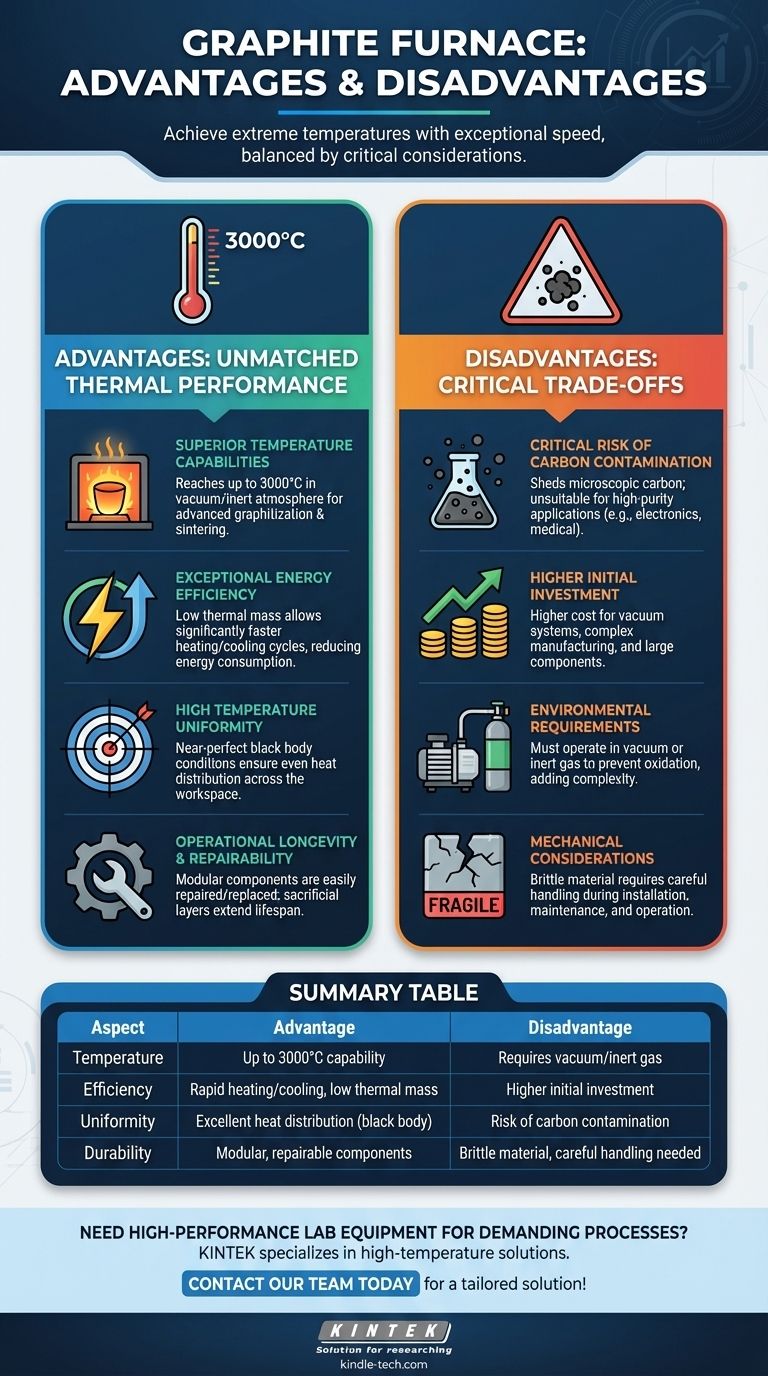

The Core Advantages: Unmatched Thermal Performance

The decision to use a graphite furnace almost always centers on its superior handling of extreme heat and energy.

Superior Temperature Capabilities

Graphite's physical structure allows it to maintain stability at temperatures up to 3000°C in a vacuum or inert atmosphere. This makes it one of the few practical materials for processes like graphitization and sintering advanced ceramics.

Exceptional Energy Efficiency

Graphite has a low density and therefore a low thermal mass. This means less energy is wasted heating the furnace itself, allowing for significantly faster heating and cooling cycles compared to heavier metallic furnaces. This translates directly to reduced energy consumption and higher throughput.

High Temperature Uniformity

Graphite creates near-perfect black body conditions (emissivity of ~1.0) inside the heating chamber. This property ensures that heat radiates evenly, resulting in exceptional temperature uniformity across the entire workspace, which is critical for consistent material processing.

Operational Longevity and Repairability

Graphite furnace chambers and insulation components are often modular and easily repaired or replaced. Sacrificial layers of graphite can also be used to protect core components, extending the overall lifespan of the furnace.

Understanding the Trade-offs and Disadvantages

While powerful, graphite furnaces introduce specific challenges that must be carefully managed. The choice to use one is an acceptance of these trade-offs.

The Critical Risk of Carbon Contamination

This is the single most significant disadvantage of a graphite furnace. Graphite can shed microscopic particles and absorb process vapors, which can then be released in subsequent cycles. This carbon contamination makes graphite furnaces entirely unsuitable for applications requiring absolute purity, such as processing sensitive electronics or medical-grade alloys.

Higher Initial Investment

Graphite-resistance furnaces, particularly those requiring a vacuum environment, have a higher initial purchasing cost. The complexity of manufacturing large graphite components and the necessary vacuum systems contributes to this expense.

Environmental Requirements

To prevent rapid oxidation at high temperatures, graphite furnaces must be operated in a vacuum or an inert gas atmosphere. This adds complexity and cost, requiring robust vacuum pumps, seals, and control systems that are not necessary for many air-atmosphere metallic furnaces.

Mechanical and Handling Considerations

Graphite is a brittle material. While strong under compression, its components require careful handling during installation, maintenance, and operation to prevent chipping or cracking.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on balancing the process requirements with the inherent material limitations.

- If your primary focus is achieving extreme temperatures (>2000°C) for materials like ceramics or carbon: A graphite furnace is often the only practical and efficient choice.

- If your primary focus is processing materials where even trace carbon is unacceptable: You must use a metallic furnace (e.g., molybdenum or tungsten) to avoid contamination.

- If your primary focus is rapid thermal cycling and energy efficiency in a high-temperature range: Graphite's low thermal mass provides a clear advantage over denser refractory metals.

Ultimately, a graphite furnace is a high-performance tool designed for specific, demanding thermal processing tasks where its benefits outweigh its significant limitations.

Summary Table:

| Aspect | Advantage | Disadvantage |

|---|---|---|

| Temperature | Up to 3000°C capability | Requires vacuum/inert gas |

| Efficiency | Rapid heating/cooling, low thermal mass | Higher initial investment |

| Uniformity | Excellent heat distribution (black body) | Risk of carbon contamination |

| Durability | Modular, repairable components | Brittle material, careful handling needed |

Need a high-performance furnace for your demanding lab processes? KINTEK specializes in high-temperature lab equipment, including graphite furnaces, serving research and industrial laboratories. Our experts can help you determine if a graphite furnace is the right choice for your specific application, ensuring you achieve superior thermal processing without compromise. Contact our team today to discuss your requirements and get a tailored solution!

Visual Guide

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What is the temperature of graphite furnace atomic absorption spectrometry? Mastering the Multi-Stage Heating Program

- What is the use of graphite furnace? Achieve Extreme-Temperature Processing for Advanced Materials

- What is the disadvantage of graphite furnace? Managing Reactivity and Contamination Risks

- What is the application of graphite furnace? Essential for High-Temp Material Processing & Synthesis

- What are the advantages of graphite furnace over flame? Achieve Superior Trace Analysis Sensitivity

- What is the graphite furnace used for? Achieve Extreme Heat Up to 3000°C in a Controlled Environment

- Why is graphite used for heat transfer? For Superior In-Plane Thermal Conductivity

- What is the difference between graphite furnace and flame AAS? Choose the Right Technique for Your Lab