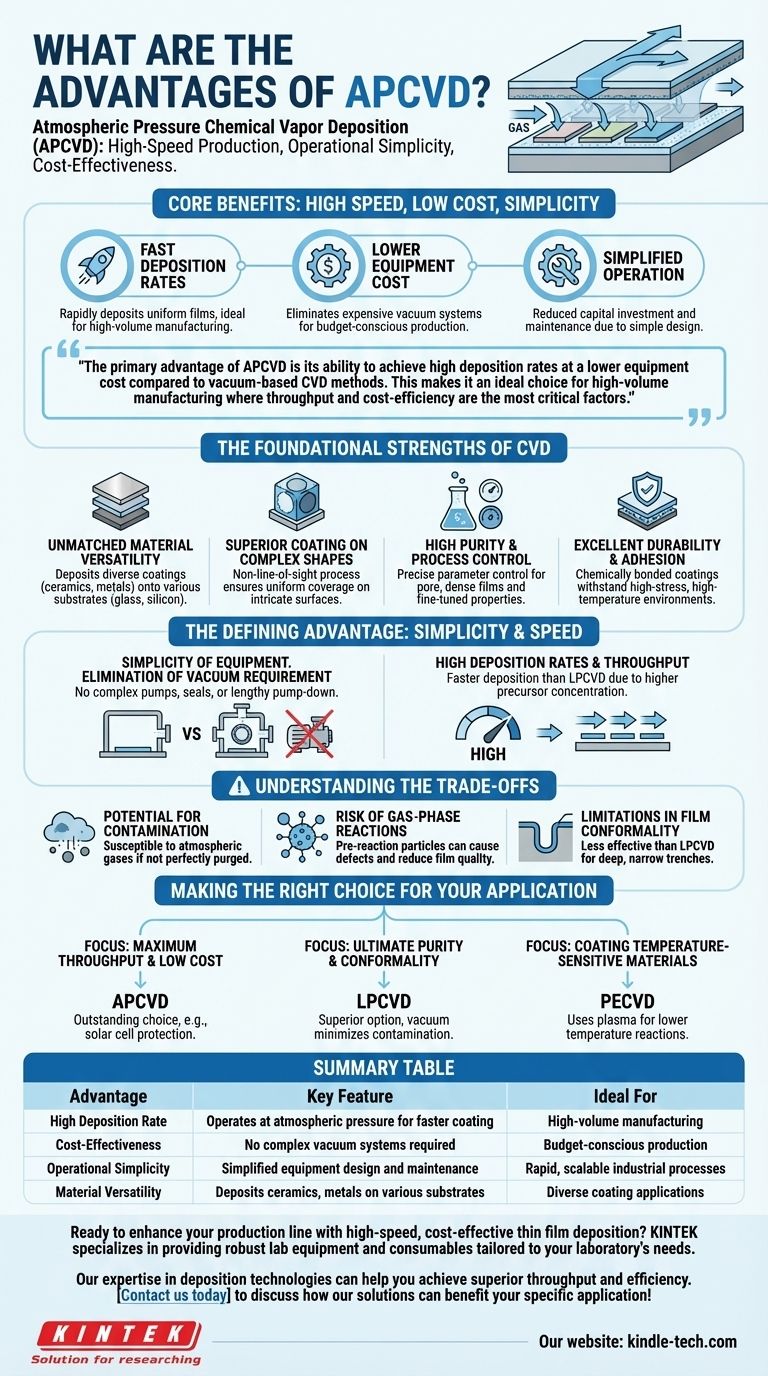

At its core, Atmospheric Pressure Chemical Vapor Deposition (APCVD) offers a powerful combination of high-speed production, operational simplicity, and cost-effectiveness. Because it operates without the need for expensive and complex vacuum systems, APCVD excels at rapidly depositing uniform, high-purity films, making it a highly scalable and economical solution for many industrial applications.

The primary advantage of APCVD is its ability to achieve high deposition rates at a lower equipment cost compared to vacuum-based CVD methods. This makes it an ideal choice for high-volume manufacturing where throughput and cost-efficiency are the most critical factors.

The Foundational Strengths of CVD

APCVD is a member of the broader Chemical Vapor Deposition (CVD) family of processes. As such, it inherits the powerful foundational benefits that make CVD a cornerstone of modern materials science and manufacturing.

Unmatched Material Versatility

The process is not limited to a single type of material. APCVD can be used to deposit a wide range of coatings, including ceramics and metals, onto various substrates like glass and silicon wafers.

Superior Coating on Complex Shapes

CVD is a non-line-of-sight process. The precursor gases flow and react around an entire component, ensuring that even complex, intricate surfaces receive a uniform and complete coating, something impossible for many physical deposition techniques.

High Purity and Process Control

The nature of the chemical reaction allows for the creation of exceptionally pure and dense films. Key parameters like temperature, gas flow, and precursor concentration can be precisely controlled to fine-tune the chemical and physical properties of the final coating.

Excellent Durability and Adhesion

The deposited films are not merely sitting on the surface; they are chemically bonded to it. This results in highly durable coatings that exhibit commendable adhesion and can withstand high-stress, high-temperature environments.

The Defining Advantage of APCVD: Simplicity and Speed

While APCVD shares the core benefits of all CVD processes, its operation at normal atmospheric pressure gives it two defining advantages that set it apart from its low-pressure counterparts.

Simplicity of Equipment

The most significant advantage is the elimination of the vacuum requirement. APCVD systems do not need expensive high-vacuum pumps, complex chamber seals, or lengthy pump-down cycles. This drastically simplifies the equipment design, reducing both capital investment and maintenance costs.

High Deposition Rates and Throughput

Operating at atmospheric pressure allows for a higher concentration of precursor gases to be delivered to the substrate. This directly translates to significantly faster deposition rates compared to low-pressure CVD (LPCVD). This high speed makes APCVD exceptionally well-suited for continuous, high-throughput industrial production.

Understanding the Trade-offs

No single technology is a universal solution. The operational simplicity of APCVD introduces specific trade-offs that are critical to understand when evaluating it against other deposition methods.

Potential for Contamination

Operating at atmospheric pressure means the reaction chamber is more susceptible to contamination from atmospheric gases like oxygen or water vapor if not perfectly purged. This can impact the ultimate purity of the film compared to a high-vacuum process.

Risk of Gas-Phase Reactions

The higher pressure and concentration of reactant gases in an APCVD system increase the likelihood of chemical reactions occurring in the gas phase before the precursors reach the substrate. This can form particles that fall onto the surface, creating defects and reducing the quality of the film.

Limitations in Film Conformality

While good, the ability of APCVD to uniformly coat extremely deep and narrow trenches (high aspect ratios) can be less effective than methods like LPCVD. The higher pressure can impede the free movement of gas molecules into these tight spaces, leading to a less uniform coating.

Making the Right Choice for Your Application

Selecting the correct deposition technology requires aligning its specific strengths and weaknesses with your primary goal.

- If your primary focus is maximum throughput and low cost: APCVD is an outstanding choice, particularly for applications like depositing protective silicon dioxide layers in solar cell or semiconductor manufacturing.

- If your primary focus is ultimate film purity and perfect uniformity on complex microstructures: A Low-Pressure CVD (LPCVD) process is likely the superior option, as the vacuum environment minimizes contamination and enhances conformality.

- If your primary focus is coating temperature-sensitive materials: You should consider Plasma-Enhanced CVD (PECVD), which uses plasma to enable reactions at much lower temperatures than thermally-driven APCVD.

Ultimately, understanding these trade-offs empowers you to select the most effective and economical tool for your specific manufacturing challenge.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| High Deposition Rate | Operates at atmospheric pressure for faster coating | High-volume manufacturing |

| Cost-Effectiveness | No complex vacuum systems required | Budget-conscious production |

| Operational Simplicity | Simplified equipment design and maintenance | Rapid, scalable industrial processes |

| Material Versatility | Deposits ceramics, metals on various substrates | Diverse coating applications |

Ready to enhance your production line with high-speed, cost-effective thin film deposition? KINTEK specializes in providing robust lab equipment and consumables tailored to your laboratory's needs. Our expertise in deposition technologies can help you achieve superior throughput and efficiency. Contact us today to discuss how our solutions can benefit your specific application!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained