In a hospital environment, the primary advantage of autoclaving is its unparalleled ability to achieve complete sterilization. It uses pressurized, high-temperature steam to destroy all forms of microbial life—including bacteria, viruses, fungi, and highly resistant spores—on medical instruments, making it the gold standard for preventing healthcare-associated infections.

The core value of autoclaving is not just its effectiveness, but its reliability. It provides a scientifically verifiable, non-toxic, and efficient method to ensure medical equipment is absolutely sterile, a non-negotiable requirement for patient safety.

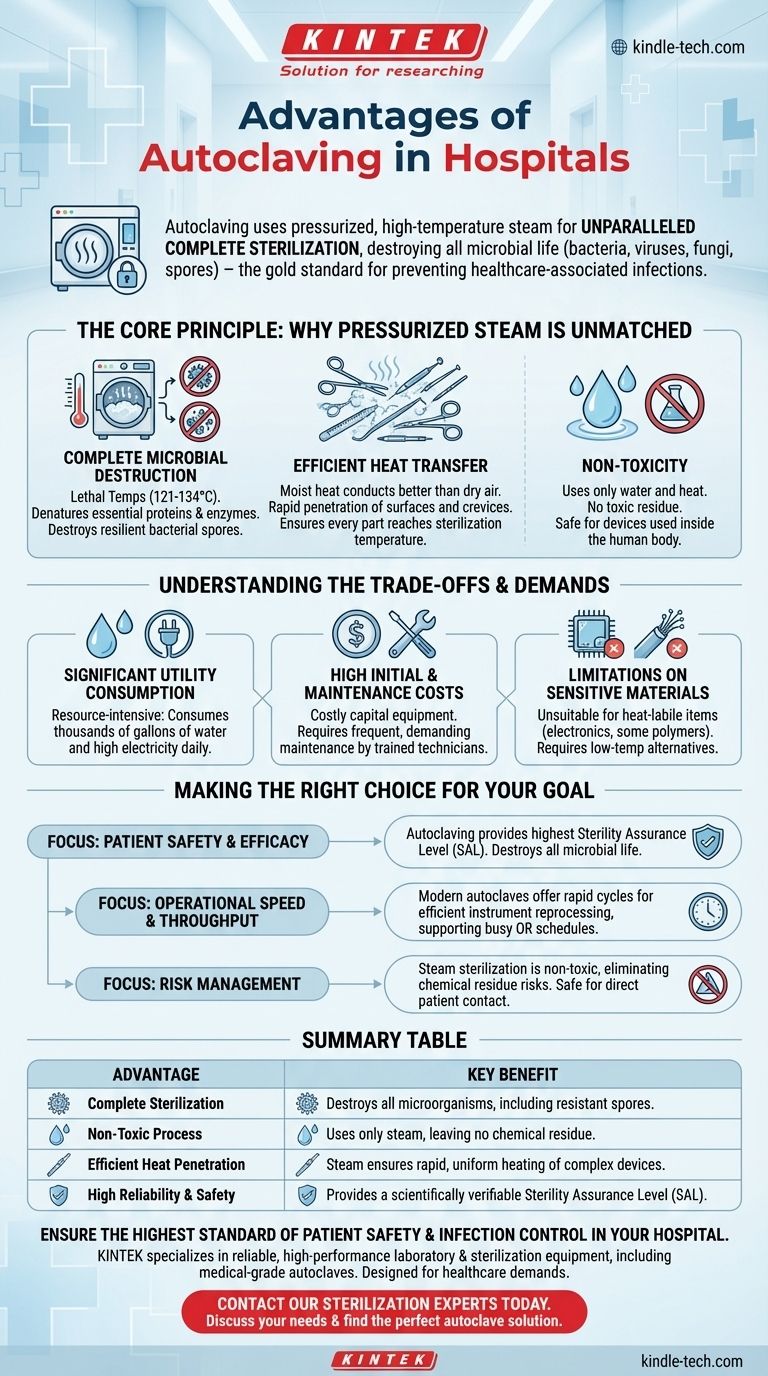

The Core Principle: Why Pressurized Steam is Unmatched

The effectiveness of autoclaving comes down to the physics of steam under pressure. This method is superior to simple boiling or dry heat for several fundamental reasons.

Complete Microbial Destruction

An autoclave operates at temperatures (typically 121-134°C or 250-273°F) and pressures that are lethal to all microorganisms. The moist heat rapidly denatures the essential proteins and enzymes that microbes, particularly resilient bacterial spores, need to survive.

Efficient Heat Transfer

Moist heat from steam is a far more effective conductor than dry air. It quickly penetrates the surfaces and crevices of complex surgical instruments, transferring thermal energy and ensuring that every part of the device reaches the required sterilization temperature.

Non-Toxicity

Unlike chemical sterilization methods, autoclaving uses only water and heat. This process leaves no toxic residue on the instruments. This is critically important for devices that will be used inside the human body, eliminating the risk of adverse chemical reactions for the patient.

Understanding the Trade-offs and Demands

While it is the preferred method, operating medical-grade autoclaves involves significant operational commitments. Understanding these demands provides context for why they are such a critical hospital investment.

Significant Utility Consumption

As regulated devices optimized for continuous use, hospital autoclaves are resource-intensive. They can consume thousands of gallons of water and high amounts of electric power each day to generate the necessary steam and run cooling cycles.

High Initial and Maintenance Costs

Medical-grade autoclaves are costly capital equipment. Furthermore, they require demanding and frequent maintenance by trained technicians to ensure they remain calibrated, safe, and effective, meeting strict regulatory standards.

Limitations on Sensitive Materials

The high heat and moisture make autoclaving unsuitable for heat-labile (heat-sensitive) materials. Devices containing delicate electronics, certain polymers, or fiber optics would be destroyed by the process, requiring alternative low-temperature sterilization methods.

Making the Right Choice for Your Goal

The decision to rely on autoclaving is a foundational element of a hospital's entire infection control strategy.

- If your primary focus is patient safety and efficacy: Autoclaving provides the highest possible Sterility Assurance Level (SAL) by reliably destroying all forms of microbial life.

- If your primary focus is operational speed and throughput: Modern autoclaves offer rapid cycles that enable the efficient reprocessing of critical surgical instruments, supporting a busy operating room schedule.

- If your primary focus is risk management: Steam sterilization is a non-toxic process that eliminates the risks associated with chemical residues, ensuring devices are safe for direct patient contact.

Ultimately, the autoclave remains the cornerstone of modern sterile processing because it delivers the highest level of certainty in infection prevention.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Complete Sterilization | Destroys all microorganisms, including resistant spores. |

| Non-Toxic Process | Uses only steam, leaving no chemical residue on instruments. |

| Efficient Heat Penetration | Steam ensures rapid, uniform heating of complex devices. |

| High Reliability & Safety | Provides a scientifically verifiable Sterility Assurance Level (SAL). |

Ensure the highest standard of patient safety and infection control in your hospital.

KINTEK specializes in providing reliable, high-performance laboratory and sterilization equipment, including medical-grade autoclaves. Our solutions are designed to meet the demanding needs of healthcare facilities, ensuring your instruments are sterile, safe, and ready for use.

Let us help you build a robust infection prevention strategy. Contact our sterilization experts today to discuss your hospital's needs and find the perfect autoclave solution.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Vacuum Freeze Dryer

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What is the most common machine used to sterilize medical supplies? The Definitive Guide to Autoclaves

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab