In short, the primary advantages of a filter press are its ability to produce an exceptionally dry solid product and its versatility in handling different materials. This is achieved through a mechanically simple and robust process that offers a high degree of control, particularly in laboratory or small-volume applications.

A filter press excels where the primary goal is maximum solid-liquid separation. Its core advantage is not speed, but the ability to generate the driest possible solid "cake" and the clearest possible liquid "filtrate" through direct mechanical pressure.

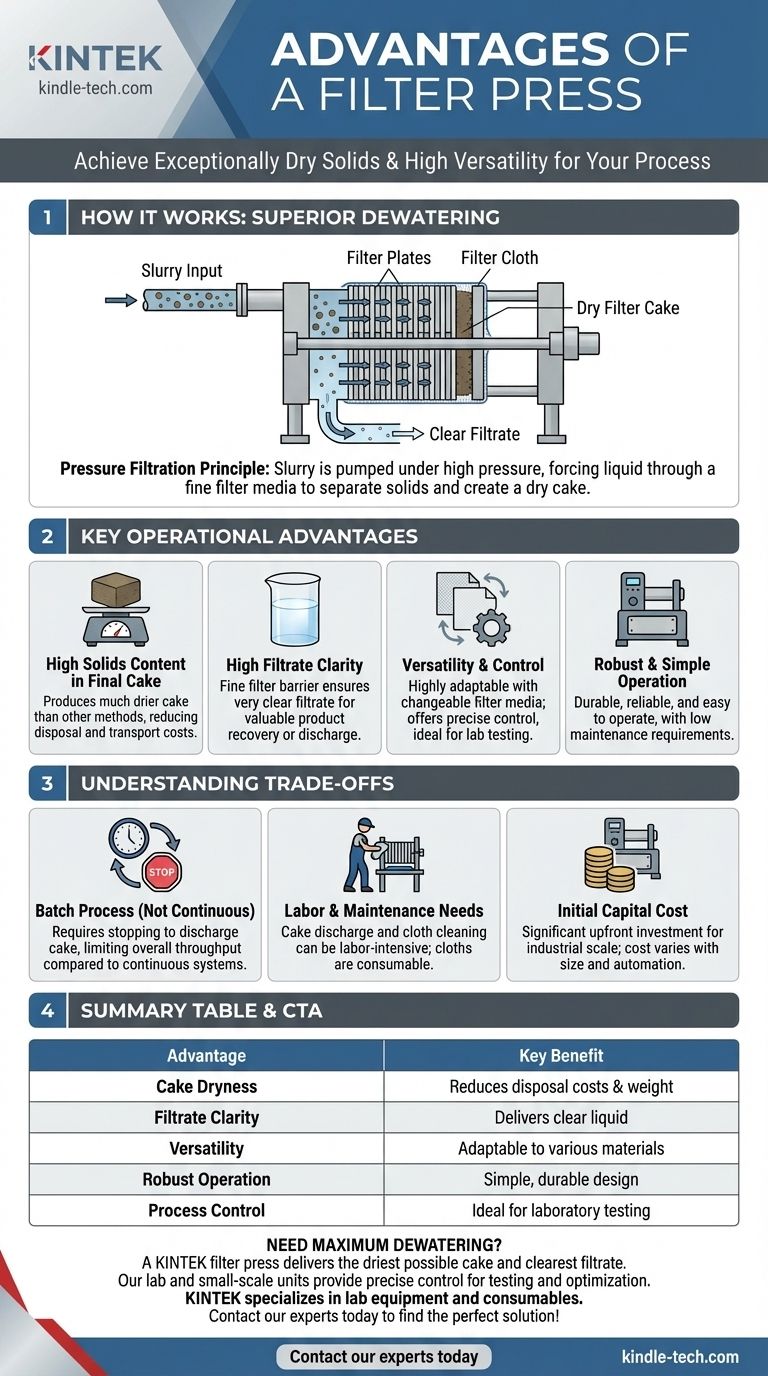

How a Filter Press Achieves Superior Dewatering

A filter press operates on a straightforward principle of pressure filtration. Understanding its core components explains its effectiveness.

The Basic Components

The system consists of a heavy-duty frame that holds a series of filter plates pressed tightly together. Each plate is dressed with a filter cloth, and a manifold system of pipes and valves feeds the slurry into the press.

The Filtration Cycle

Slurry is pumped into the chambers between the filter plates. The liquid, or filtrate, is forced through the filter cloth and exits through ports, while the solids are trapped. As more slurry is pumped in, pressure builds, squeezing more liquid out until the chambers are filled with a compact, dewatered solid known as filter cake.

Key Operational Advantages

The simple design of the filter press leads to several distinct operational benefits that make it the right choice for specific applications.

High Solids Content in Final Cake

This is the most significant advantage. By applying high mechanical pressure, a filter press can produce a final cake with a much higher solids percentage (meaning less water) than many other dewatering technologies. A drier cake reduces disposal costs and weight for transport.

High Filtrate Clarity

The filter cloth acts as a fine barrier, resulting in a very clear filtrate. This is critical in applications where the liquid is the valuable product or needs to be discharged with minimal solid contaminants.

Versatility and Control

Filter presses are highly adaptable. You can change the filter media (the cloth) to suit different particle sizes and materials. In laboratory settings, this provides a high degree of control for testing and process optimization on a small scale.

Robust and Simple Operation

The technology is mechanically simple and has few moving parts during the filtration cycle. This makes filter presses durable, reliable, and relatively easy to operate, especially smaller, manually operated units which are often built with corrosion-resistant stainless steel.

Understanding the Trade-offs

No technology is perfect. The effectiveness of a filter press comes with important considerations that may make it unsuitable for certain goals.

A Batch Process, Not Continuous

The most significant trade-off is that a filter press operates in batches. The process must be stopped to open the press and discharge the solid cake. This downtime, known as the "cycle time," limits overall throughput compared to continuous systems like a belt press or centrifuge.

Labor and Maintenance Requirements

Discharging the cake and cleaning the filter cloths can be labor-intensive, especially on large, manual presses. While automation is available, it adds to the complexity and cost. The filter cloths are also a consumable item that requires periodic replacement.

Initial Capital Cost

While laboratory models are relatively low-cost, industrial-scale filter presses represent a significant capital investment. The required size and level of automation will directly impact the upfront expense.

Making the Right Choice for Your Goal

To decide if a filter press is right for you, consider your primary objective.

- If your primary focus is maximum dewatering: A filter press is an excellent choice for producing the driest possible solid cake, which minimizes disposal costs.

- If your primary focus is process testing or small-volume filtration: A laboratory filter press offers unparalleled control and versatility at a manageable cost.

- If your primary focus is high-volume, continuous throughput with minimal labor: The batch nature of a filter press may be a bottleneck; you should evaluate continuous technologies as an alternative.

Ultimately, the filter press remains a premier technology for applications where final cake dryness and filtrate clarity are more critical than continuous operation.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Cake Dryness | Produces high solids content, reducing disposal costs & weight. |

| Filtrate Clarity | Delivers clear liquid through fine filter media. |

| Versatility | Adaptable to various materials with different filter cloths. |

| Robust Operation | Simple, durable design with few moving parts. |

| Process Control | Ideal for laboratory testing and small-volume applications. |

Need to achieve maximum dewatering for your process?

A KINTEK filter press delivers the driest possible solid cake and clearest filtrate, directly reducing your disposal costs and improving product quality. Our laboratory and small-scale units provide the precise control and versatility you need for testing and optimization.

KINTEK specializes in lab equipment and consumables, serving all your laboratory filtration needs.

Contact our experts today to find the perfect filter press solution for your specific application!

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the factors that affect the filtration of the solution? Master the Key Variables for Optimal Performance

- What happens if a hydraulic system leaks? Prevent Costly Damage and Safety Hazards

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid

- What are some of the problems related to hydraulic power? Manage Leaks, Contamination, and Inefficiency