The fundamental advantage of furnace brazing is its ability to produce exceptionally strong, clean, and dimensionally accurate joints at scale. Unlike welding, which applies intense, localized heat, furnace brazing uses a controlled thermal cycle to heat an entire assembly uniformly. This core difference allows for the creation of complex components from dissimilar materials with minimal distortion or residual stress.

Furnace brazing transforms metal joining from a localized, high-impact operation into a precisely controlled, holistic process. This shift is the source of its primary benefits: superior part integrity, expanded design freedom, and significant manufacturing efficiency.

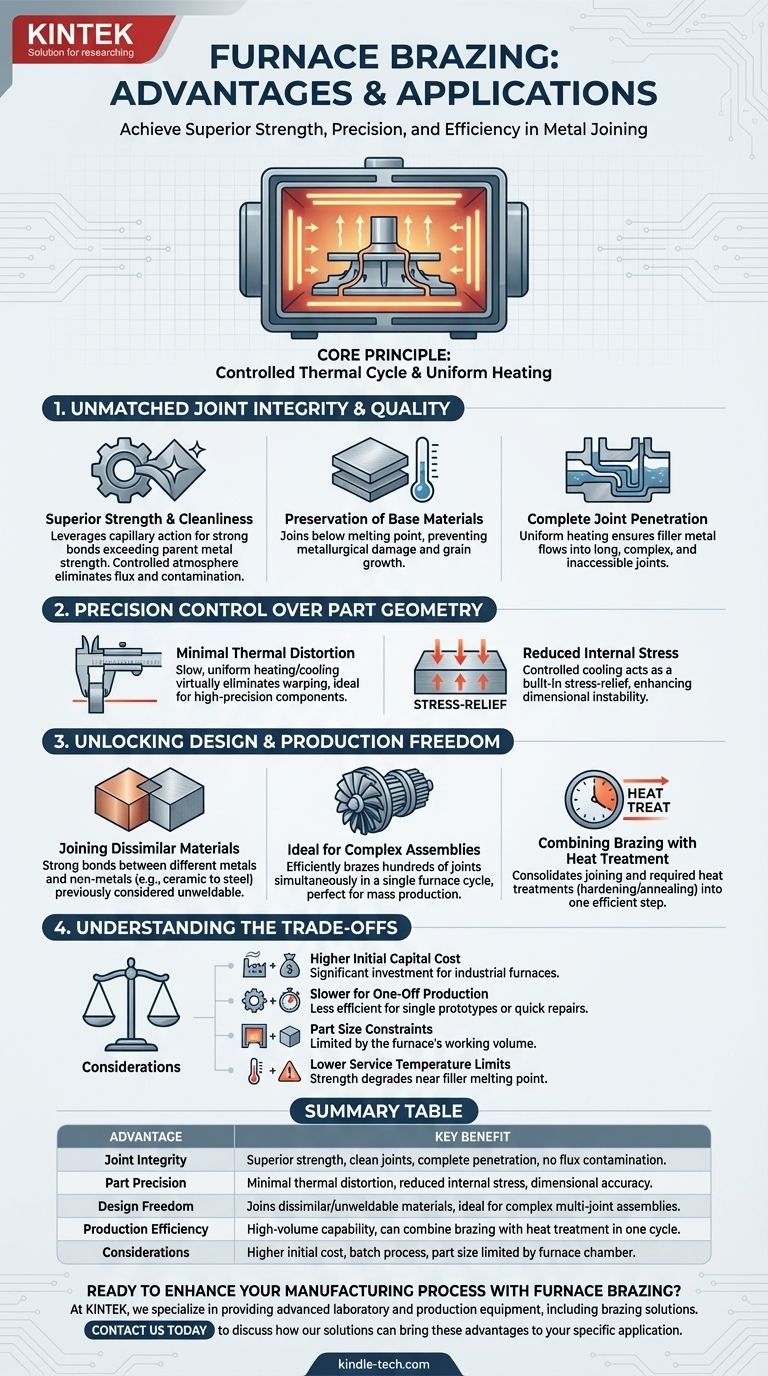

Unmatched Joint Integrity and Quality

The controlled environment of a brazing furnace is the key to producing superior joints that often outperform the base materials themselves.

Superior Strength and Cleanliness

A properly designed brazed joint leverages capillary action to draw the molten filler metal into the interface between the parts. This creates a bond that is incredibly strong, often exceeding the tensile strength of the parent metals. Because the process typically occurs in a vacuum or a controlled atmosphere, it eliminates the need for flux, preventing contamination and resulting in clean joints that require little to no post-braze finishing.

Preservation of Base Materials

Furnace brazing joins materials without melting them. The process temperature is always lower than the melting point of the components being joined. This is critical because it avoids the metallurgical damage, grain growth, and potential property degradation associated with fusion welding.

Complete Joint Penetration

The uniform heating allows the entire assembly to reach brazing temperature simultaneously. This enables the filler metal to flow into long, complex, or internally inaccessible joints, ensuring a complete and void-free bond that would be impossible to achieve with localized heating methods.

Precision Control Over Part Geometry

For applications where dimensional accuracy is paramount, furnace brazing offers a level of control that other high-temperature joining methods struggle to match.

Minimal Thermal Distortion

By heating and cooling the entire assembly slowly and uniformly, furnace brazing virtually eliminates the thermal distortion and warping common in welding. This makes it the ideal choice for high-precision assemblies, delicate components, or parts with strict geometric tolerances.

Reduced Internal Stress

The controlled cooling cycle of the furnace process acts as a built-in stress-relief operation. This significantly reduces the residual stress that can lead to premature failure or dimensional instability in the finished part. In many cases, it combines brazing and a required stress-relief heat treatment into a single, efficient step.

Unlocking Design and Production Freedom

Furnace brazing removes many of the constraints imposed by traditional joining methods, allowing for greater innovation in both design and manufacturing.

Joining Dissimilar and "Unweldable" Materials

One of the most powerful advantages of furnace brazing is its ability to create strong bonds between wildly different materials. It can join various metals (like copper to steel), non-metals to metals (like ceramic to steel), and materials that are considered unweldable by conventional means.

Ideal for Complex Assemblies

The process is uniquely suited for manufacturing complex components with multiple joints. An assembly with dozens or even hundreds of joints can be brazed simultaneously in a single furnace cycle. This makes it highly efficient and cost-effective for mass production of intricate parts like heat exchangers or turbine assemblies.

Combining Brazing with Heat Treatment

The thermal cycle of furnace brazing can be engineered to do double duty. By carefully controlling the heating and cooling rates, it's possible to combine the joining process with a required heat treatment, such as hardening or annealing. This consolidation of steps saves significant time, handling, and cost.

Understanding the Trade-offs

While powerful, furnace brazing is not the universal solution for all joining applications. Objectivity requires acknowledging its limitations.

Higher Initial Capital Cost

Industrial furnaces, particularly vacuum furnaces, represent a significant capital investment compared to the equipment needed for manual joining methods like TIG or torch brazing.

Slower for One-Off Production

The process is optimized for batches. The time required to heat and cool the furnace makes it inefficient for a single, quick repair or one-off prototype compared to a direct-heat method.

Part Size Constraints

The component being brazed must be able to fit within the furnace's working volume. This can be a limitation for very large assemblies.

Lower Service Temperature Limits

A brazed joint's mechanical strength begins to degrade as its service temperature approaches the melting point of the filler alloy. Welded joints, by contrast, typically have a service temperature limit closer to that of the parent metal.

Making the Right Choice for Your Goal

Selecting the right joining process depends entirely on your project's specific priorities.

- If your primary focus is high-volume production of complex parts: Furnace brazing offers unmatched repeatability and cost-effectiveness by creating numerous joints in a single, automated cycle.

- If your primary focus is maintaining tight tolerances and preventing distortion: The uniform heating and cooling inherent to the process make it superior to any method that applies intense, localized heat.

- If your primary focus is joining dissimilar or difficult-to-weld materials: Furnace brazing is one of the most reliable and robust methods for creating strong bonds between materials that cannot be fusion welded.

- If your primary focus is maximizing process efficiency: Combining heat treatment with brazing and eliminating post-process cleaning significantly reduces production steps, handling, and overall cost.

By understanding its core principles, you can leverage furnace brazing to move beyond simple joining and achieve superior, highly engineered manufacturing outcomes.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Joint Integrity | Superior strength, clean joints, complete penetration, no flux contamination |

| Part Precision | Minimal thermal distortion, reduced internal stress, dimensional accuracy |

| Design Freedom | Joins dissimilar/unweldable materials, ideal for complex multi-joint assemblies |

| Production Efficiency | High-volume capability, can combine brazing with heat treatment in one cycle |

| Considerations | Higher initial cost, batch process, part size limited by furnace chamber |

Ready to enhance your manufacturing process with furnace brazing?

At KINTEK, we specialize in providing advanced laboratory and production equipment, including brazing solutions, to meet the demanding needs of industries requiring high-integrity metal joining. Our expertise can help you achieve stronger bonds, higher precision, and greater efficiency in your production line.

Contact us today via our [#ContactForm] to discuss how our solutions can bring these advantages to your specific application. Let KINTEK be your partner in precision manufacturing.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining