The primary advantages of sintering are its ability to fundamentally enhance a material's physical properties while enabling the cost-effective, high-volume production of complex parts. The process transforms powdered materials into a solid, coherent mass, significantly increasing strength, density, and conductivity. This makes it a powerful alternative to traditional casting or machining for a wide range of applications.

Sintering is not merely a fabrication technique; it is a transformative process. Its core value lies in creating near net-shape components with superior, tightly controlled material properties directly from powder, often bypassing the complexities and limitations of melting or subtractive manufacturing.

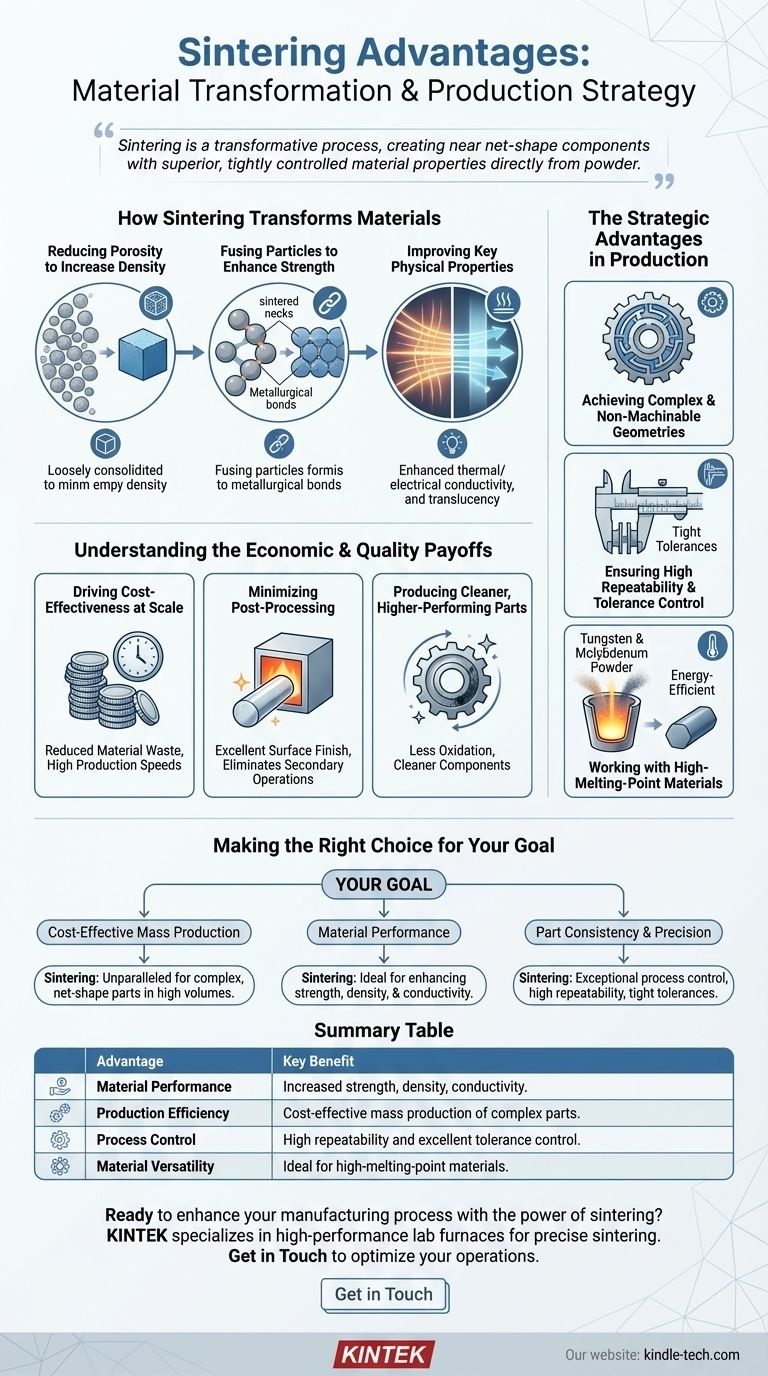

How Sintering Fundamentally Transforms Materials

The true power of sintering begins at the microscopic level. By applying heat below the material's melting point, it fundamentally rearranges the particulate structure to create a stronger, denser final product.

Reducing Porosity to Increase Density

Sintering systematically reduces the empty spaces, or porosity, between the initial powder particles.

This consolidation is a primary driver for improving nearly all other material properties, from strength to thermal conductivity.

Fusing Particles to Enhance Strength

The process encourages the formation of strong metallurgical bonds, or "sintered necks," between adjacent particles.

This atomic diffusion fuses the powder into a solid, cohesive piece, drastically increasing its overall strength, integrity, and durability compared to the initial compacted powder.

Improving Key Physical Properties

By creating a more unified and dense material, sintering significantly improves its performance characteristics.

This includes enhanced thermal and electrical conductivity as well as improved translucency in certain ceramic materials, making it valuable for technical applications.

The Strategic Advantages in Production

Beyond improving the material itself, sintering offers significant strategic advantages on the production floor, enabling outcomes that are difficult or impossible with other methods.

Achieving Complex and Non-Machinable Geometries

Sintering excels at producing parts with highly complex shapes and intricate internal features.

Because the initial shape is formed by pressing powder in a die, it allows for the mass production of geometries that would be prohibitively expensive or physically impossible to create through machining.

Ensuring High Repeatability and Tolerance Control

The process is highly repeatable, delivering exceptional consistency from one part to the next.

This allows for excellent tolerance control over large production runs, ensuring that each component meets precise design specifications with minimal variation.

Working with High-Melting-Point Materials

Sintering is exceptionally useful for materials with extremely high melting points, such as tungsten or molybdenum.

It allows these materials to be formed into dense, solid parts without having to reach the extreme temperatures required for melting, making the process more energy-efficient and controllable.

Understanding the Economic and Quality Payoffs

The benefits of sintering extend directly to the quality of the final part and the efficiency of the manufacturing process, resulting in clear economic advantages.

Driving Cost-Effectiveness at Scale

The ability to produce near net-shape parts dramatically reduces material waste compared to subtractive methods like machining.

This efficiency, combined with high production speeds, makes sintering an extremely cost-effective solution for medium- to high-volume manufacturing.

Minimizing Post-Processing

Sintered parts often come out of the furnace with an excellent surface finish.

This frequently eliminates the need for secondary finishing operations, saving both time and money in the production cycle.

Producing Cleaner, Higher-Performing Parts

Compared to other high-temperature metalworking techniques, sintering produces less soot and oxidation.

The process also helps remove residual lubricants and surface impurities from the initial compaction stage, resulting in cleaner, brighter, and higher-performing components.

Making the Right Choice for Your Goal

To determine if sintering is the optimal path, consider your project's primary driver.

- If your primary focus is cost-effective mass production: Sintering is unparalleled for creating complex, net-shape parts in high volumes with minimal material waste.

- If your primary focus is material performance: The process is ideal for enhancing properties like strength, density, and conductivity, especially in materials that are difficult to melt or machine.

- If your primary focus is part consistency and precision: Sintering offers exceptional process control, yielding highly repeatable parts with tight tolerances directly from the mold.

Ultimately, sintering provides a sophisticated method for engineering both the shape of a part and the very nature of its material composition.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Performance | Increased strength, density, and thermal/electrical conductivity. |

| Production Efficiency | Cost-effective mass production of complex, near net-shape parts. |

| Process Control | High repeatability and excellent tolerance control. |

| Material Versatility | Ideal for high-melting-point materials like tungsten and molybdenum. |

Ready to enhance your manufacturing process with the power of sintering?

KINTEK specializes in providing the high-performance lab furnaces and equipment essential for precise sintering processes. Whether you are developing new materials or scaling up production, our solutions deliver the consistent, controlled heating required to achieve superior part density, strength, and complex geometries.

Contact us today using the form below to discuss how our expertise can help you optimize your sintering operations for better quality and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- Why is a precision oven necessary for SnS2 to SnO2/MoS2 catalysts? Ensure Uniform Phase & Epitaxial Growth

- What is a microwave pyrolysis reactor? A Guide to Faster, More Efficient Thermal Processing

- How do you remove solvent by evaporation? Master the Techniques for Safe and Efficient Sample Preparation

- Is it illegal to make lab-grown diamonds? The Truth About Legality and Transparency

- What industries use heat treatment? A Guide to Enhancing Material Performance Across Sectors

- What is the impregnation method of catalyst preparation? Achieve High Dispersion & Activity

- What are the typical common apparatus used for heating in laboratory? Ensure Safe & Precise Heating

- What are the raw materials for biochar production? Choose the Right Feedstock for Your Goals