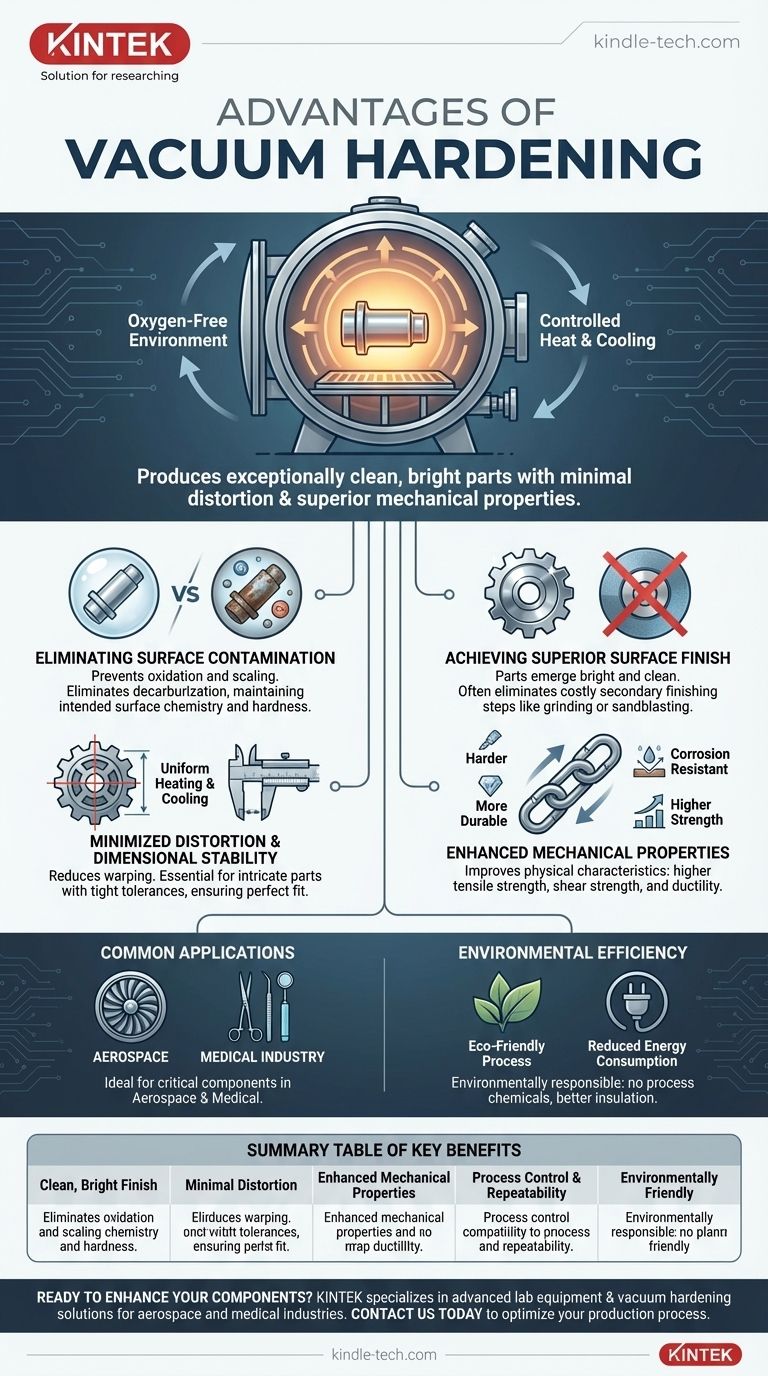

The primary advantages of vacuum hardening are its ability to produce exceptionally clean, bright parts with minimal distortion and superior mechanical properties. By performing the heat treatment process in an oxygen-free environment, it prevents surface reactions like oxidation and decarburization, ensuring high purity and dimensional stability for critical components.

The fundamental benefit of vacuum hardening is not just strengthening metal, but doing so with unparalleled precision and surface integrity. This controlled, clean process eliminates many common defects and secondary finishing steps associated with traditional heat treatment methods.

How It Works and Why It Matters

Vacuum hardening is a specialized heat treatment process where components are heated to temperatures up to 1,300°C and then rapidly cooled (quenched) under a controlled partial pressure, or vacuum. The removal of atmosphere, particularly oxygen, is the key to its distinct advantages.

Eliminating Surface Contamination

In traditional heat treatment, atmospheric oxygen reacts with the hot metal surface, causing scaling and oxidation. Vacuum hardening creates an oxygen-free environment, which prevents these surface reactions entirely.

This also prevents decarburization, a process where carbon leaches from the surface layer of the steel, making it softer and more prone to failure. The result is a component that maintains its intended surface chemistry and hardness.

Achieving Superior Surface Finish

Because vacuum hardening prevents scaling, parts emerge from the furnace with a bright, clean, metallic surface.

This high-quality finish often has a decorative quality and, more importantly, can eliminate the need for costly and time-consuming secondary operations like grinding, sandblasting, or chemical cleaning.

The Tangible Benefits for Your Components

The controlled nature of the vacuum furnace environment translates directly into higher quality and more reliable parts, making it a critical process for demanding industries like aerospace and medicine.

Unmatched Consistency and Control

Modern vacuum furnaces are managed by sophisticated computer controls. This ensures precise temperature uniformity and high process repeatability from batch to batch.

This level of control is critical for parts with complex geometries or for applications where consistent performance is non-negotiable, such as in the manufacturing of surgical instruments or turbine blades.

Minimized Distortion and Dimensional Stability

The uniform heating and controlled cooling inherent in the vacuum process significantly reduce the risk of distortion and warping.

This is especially crucial for intricate components or parts with tight dimensional tolerances, ensuring they maintain their specified shape and fit perfectly during assembly.

Enhanced Mechanical Properties

Metals treated with vacuum hardening exhibit significant improvements in their physical characteristics.

These parts become harder, more durable, and more resistant to corrosion. They also demonstrate higher tensile strength, shear strength, and ductility, making them suitable for a wider range of high-stress applications.

Common Applications and Environmental Efficiency

The unique benefits of vacuum hardening make it the preferred choice for industries where performance and reliability are paramount. It also offers significant operational advantages.

Ideal for Critical Industries

In the aerospace industry, vacuum hardening is used for critical components like turbine and compressor blades, improving their strength and durability while ensuring dimensional accuracy.

In the medical industry, the process produces high-strength, contamination-free surgical instruments where precision and cleanliness are absolutely essential.

An Environmentally Responsible Process

Compared to traditional methods that may use salts or other chemicals, vacuum hardening is an environmentally friendly process.

Vacuum furnaces also feature improved insulation, which leads to reduced energy consumption and more efficient operation overall.

Making the Right Choice for Your Goal

Selecting the right heat treatment process depends entirely on the specific requirements of your component and its application.

- If your primary focus is mission-critical precision and reliability: Vacuum hardening's unparalleled control and prevention of contamination make it the superior choice for aerospace and medical parts.

- If your primary focus is a perfect surface finish to reduce costs: The bright, clean result of vacuum hardening can eliminate secondary processing steps, saving time and money.

- If your primary focus is consistent quality across high-volume production: The computer-controlled repeatability of vacuum hardening ensures every part meets the exact same high standard.

Ultimately, choosing vacuum hardening is an investment in quality, precision, and process integrity.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Clean, Bright Finish | Eliminates oxidation and decarburization, removing need for secondary finishing. |

| Minimal Distortion | Uniform heating and controlled cooling ensure superior dimensional stability. |

| Enhanced Mechanical Properties | Increases hardness, strength, and durability for high-stress applications. |

| Process Control & Repeatability | Sophisticated computer controls guarantee consistent, high-quality results batch after batch. |

| Environmentally Friendly | No process chemicals required and reduced energy consumption. |

Ready to enhance the quality and reliability of your critical components?

KINTEK specializes in advanced lab equipment and consumables, including vacuum hardening solutions tailored for demanding industries like aerospace and medical manufacturing. Our expertise ensures you achieve the unparalleled precision, cleanliness, and mechanical properties your applications require.

Contact us today to discuss how our vacuum hardening solutions can optimize your production process and deliver superior results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the role of a laboratory arc melting furnace in Fe-Cu-O melt decopperization? Boost Your Research Precision

- Why is a high-vacuum high-temperature furnace required for Inconel 718? Ensure Material Integrity & Strength

- Is annealing only for steel? Unlock Material Versatility with This Essential Heat Treatment

- What is the application of vacuum brazing? Achieve Unmatched Joint Integrity for Critical Components

- What are the advantages of using a vacuum drying oven for iron nanoparticles? Prevent Oxidation & Sintering

- What is undesirable in a brazing atmosphere? Avoid These Contaminants for Stronger Joints

- Why is a high-temperature furnace with multi-probe testing used for ABO3 perovskite? Get Precise Conductivity Data

- Why are resistance furnaces used for SHS preheating? Mastering Controlled Ignition & Thermal Explosion for Lab Success