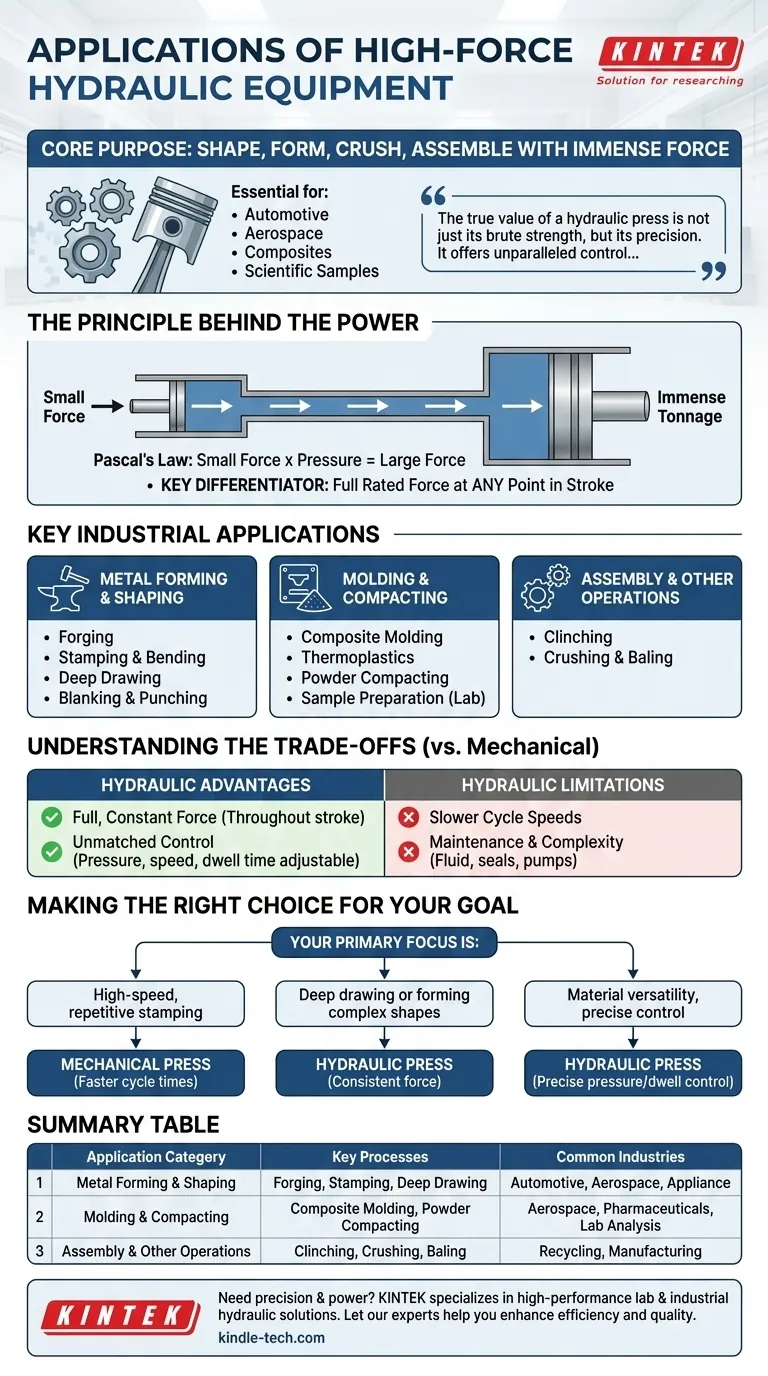

At its core, high-force hydraulic equipment, from massive presses to specialized hammers, is used across countless industries for one fundamental purpose: to shape, form, crush, or assemble materials with immense and highly controllable force. These machines are essential in manufacturing automotive parts, forming aerospace components, molding advanced composites, and even preparing scientific samples.

The true value of a hydraulic press is not just its brute strength, but its precision. It offers unparalleled control over force, speed, and position, making it one of the most versatile and indispensable tools in modern industrial production.

The Principle Behind the Power

How Force is Multiplied

A hydraulic press operates on Pascal's Law. A small force applied to a small piston in a sealed system generates pressure in a fluid (usually oil). This pressure acts on a much larger piston, multiplying the initial force to generate the immense tonnage required for industrial work.

This principle allows a relatively small motor and pump to produce forces ranging from a few tons to tens of thousands of tons.

Why This Matters for Manufacturing

The use of fluid pressure, rather than a mechanical linkage, is the key differentiator. It means the press can deliver its full rated force at any point in its stroke, not just at the bottom like a mechanical press. This capability is critical for many advanced applications.

Key Industrial Applications

Metal Forming and Shaping

This is the most common application category. Hydraulic presses excel at manipulating metal sheets and blocks into complex shapes.

Key processes include:

- Forging: Compressing a piece of metal under immense pressure to shape it and align its grain structure, increasing its strength.

- Stamping and Bending: Using dies to press flat metal sheets into specific forms, like car door panels or appliance housings.

- Deep Drawing: A process where a sheet metal blank is drawn into a forming die to create a deep, cup-like shape without wrinkles or fractures, such as a kitchen sink.

- Blanking and Punching: Using the press to shear or punch precise shapes out of a sheet of metal.

Molding and Compacting

Hydraulic presses provide the sustained pressure and temperature control needed to mold a wide range of materials beyond metals.

Common uses are:

- Composite Molding: Forming parts from Sheet Molded Composites (SMC) or carbon fiber, which require specific pressure and heat cycles to cure properly. This is vital in the aerospace and high-performance automotive industries.

- Thermoplastics: Pressing heated plastic materials into molds to create a vast array of consumer and industrial products.

- Powder Compacting: Pressing metallic or ceramic powders into solid forms, a key step in creating everything from pharmaceuticals to sintered metal parts.

- Sample Preparation: In laboratories, small hydraulic presses are used to compact powdered samples into thin pellets for analytical techniques like X-ray fluorescence (XRF).

Assembly and Other Operations

The controlled force of a hydraulic press is also used to join and assemble components.

These operations include:

- Clinching: Joining sheets of metal together by locally deforming them to create a strong mechanical interlock without fasteners or heat.

- Crushing and Baling: Used in recycling industries to compact materials like scrap cars or metal waste into dense, manageable blocks.

Understanding the Trade-offs

Choosing a hydraulic press is an engineering decision with distinct advantages and disadvantages compared to its main alternative, the mechanical press.

Advantage: Full, Constant Force

A hydraulic press can deliver its maximum rated force at any point in the stroke. This is essential for deep drawing or forming operations that require consistent pressure over a long distance. Mechanical presses only achieve full tonnage at the very bottom of their stroke.

Advantage: Unmatched Control

Pressure, stroke length, speed, and dwell time (the time the press holds pressure at the bottom of the stroke) are all easily and precisely adjustable. This flexibility is crucial for working with sensitive composites or for complex forming jobs.

Limitation: Slower Cycle Speeds

For simple, high-volume stamping where speed is the top priority, a mechanical press is often faster. The need to move hydraulic fluid makes the cycle time of a hydraulic press inherently slower.

Limitation: Maintenance and Complexity

Hydraulic systems require clean fluid, leak-free seals, and regular maintenance of pumps and valves. While modern systems are highly reliable, they can be more complex to troubleshoot than a purely mechanical system.

Making the Right Choice for Your Goal

Selecting the right type of press depends entirely on the specific demands of your manufacturing process.

- If your primary focus is high-speed, repetitive stamping of simple parts: A mechanical press is often the more efficient and economical choice due to its faster cycle times.

- If your primary focus is deep drawing or forming complex shapes: The hydraulic press is superior because it delivers consistent force throughout the entire stroke.

- If your primary focus is material versatility (e.g., composites, molding): A hydraulic press is essential for its precise control over pressure, speed, and dwell time.

Ultimately, understanding the unique capabilities of a hydraulic press allows you to apply force with intelligence, not just strength.

Summary Table:

| Application Category | Key Processes | Common Industries |

|---|---|---|

| Metal Forming & Shaping | Forging, Stamping, Deep Drawing | Automotive, Aerospace, Appliance |

| Molding & Compacting | Composite Molding, Powder Compacting | Aerospace, Pharmaceuticals, Lab Analysis |

| Assembly & Other Operations | Clinching, Crushing, Baling | Recycling, Manufacturing |

Need a hydraulic press that delivers precision and power for your specific application? KINTEK specializes in high-performance lab equipment and industrial solutions, including hydraulic presses tailored for metal forming, composite molding, and sample preparation. Our experts will help you select the right equipment to enhance your manufacturing efficiency and material quality. Contact us today to discuss your needs and discover the KINTEK advantage!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy