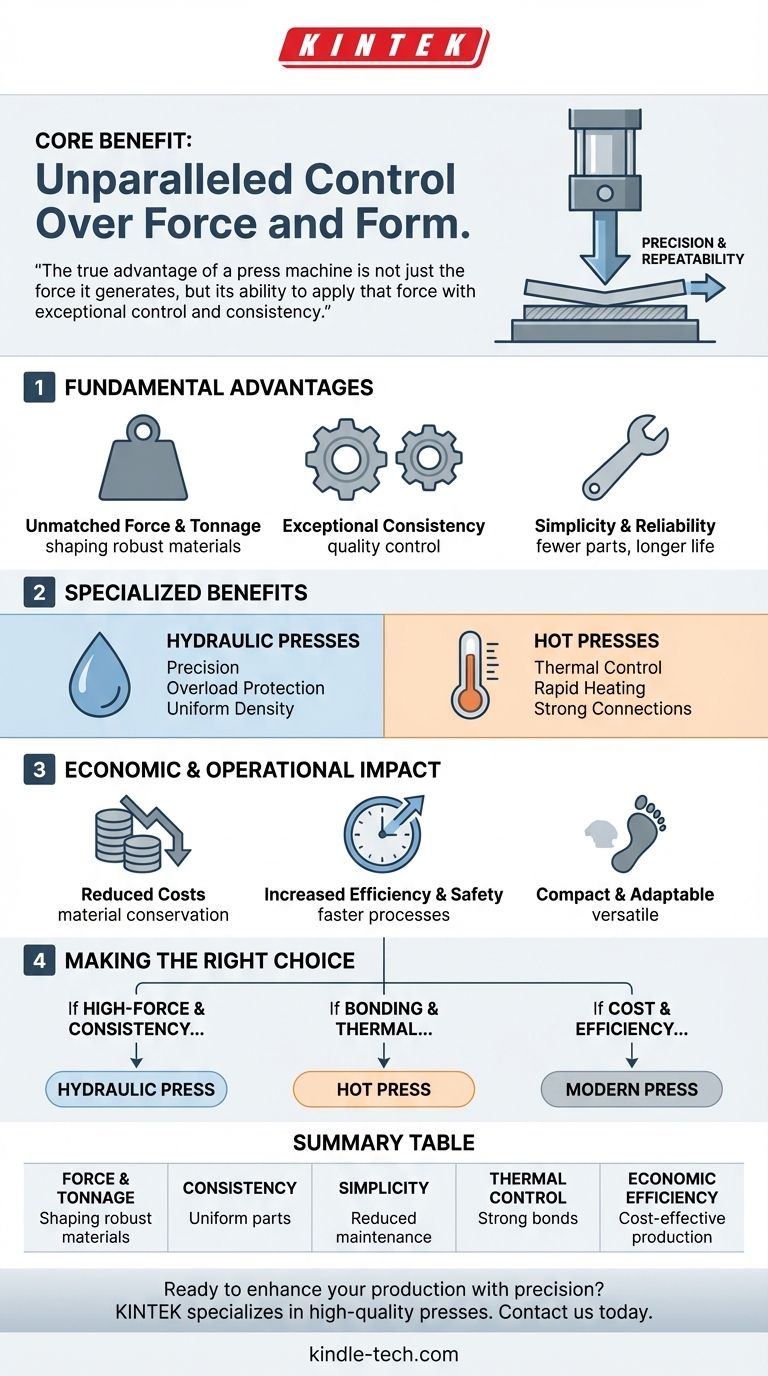

At its core, a press machine offers unparalleled control over force and form. The primary benefits are the ability to apply immense, evenly distributed pressure with high precision and repeatability. This leads to the efficient production of consistent, high-quality parts, strong material bonds, and significant cost savings through material conservation and reduced operational complexity.

The true advantage of a press machine is not just the force it generates, but its ability to apply that force with exceptional control and consistency. This repeatability is the foundation for reliable, high-quality manufacturing and testing across numerous industries.

The Fundamental Advantages of Press Technology

Press machines are foundational in modern manufacturing because they solve core challenges related to force, consistency, and efficiency. Their design principles translate into tangible operational benefits.

Unmatched Force and Tonnage

A key benefit, particularly of hydraulic presses, is the capacity to generate immense pressure. This high tonnage allows for the shaping, forming, and assembly of even the most robust materials with ease.

This capability is achieved through a simple and efficient design, which multiplies a small initial force into a massive output.

Exceptional Consistency and Repeatability

Presses excel at producing identical results time after time. Whether creating uniform pellets for FTIR spectroscopy or forming complex parts, the machine ensures that pressure and temperature are applied consistently.

This repeatability is critical for quality control, minimizing waste and guaranteeing that every component meets precise specifications.

Simplicity and Reliability

Many press designs, especially hydraulic systems, are mechanically simple with fewer moving parts compared to manual or more complex machinery.

This simplicity leads to a longer lifespan for tooling, reduced maintenance requirements, and quieter operation, contributing to a more reliable and safer work environment.

Specialized Benefits by Press Type

While all presses share core advantages, different types are optimized for specific tasks. The two primary categories, distinguished by their method of force application and thermal capabilities, offer unique benefits.

The Precision of Hydraulic Presses

Hydraulic presses are celebrated for their adaptability and control over mechanical force. They use fluid pressure to generate force, which provides inherent overload protection, safeguarding both the machine and the tooling.

Their ability to deliver consistent pressure makes them ideal for applications requiring uniform density, such as creating sample discs for laboratory analysis.

The Thermal Control of Hot Presses

Hot presses add a critical element: precisely controlled heat. These machines offer rapid heating and consistent temperature distribution across the entire pressing surface.

This combination of even pressure and temperature is essential for creating strong, permanent electrical and mechanical connections, making them indispensable in electronics manufacturing and composite material bonding.

Understanding the Economic and Operational Impact

Beyond the technical capabilities, adopting press technology has a direct and positive impact on production costs and overall efficiency.

Reduced Production and Mold Costs

Presses contribute to lower costs in several ways. Their efficiency can reduce the total number of parts needed in an assembly, which in turn lowers mold costs.

The technology also facilitates material conservation by forming parts with high precision, minimizing scrap and waste.

Increased Efficiency and Safety

The simple design and operational speed of presses, such as in the quick production of sample pellets, make manufacturing processes faster and more efficient.

Built-in features like overload protection and quieter operation enhance workplace safety and reduce the risk of costly equipment damage.

Compact and Adaptable Footprint

Compared to older or more complex machinery, modern presses often require significantly less floor space. Their inherent design simplicity and versatility allow a single machine to be adapted for a wide range of tasks.

Making the Right Choice for Your Application

To leverage these benefits effectively, you must align the machine's capabilities with your specific production goal.

- If your primary focus is high-force mechanical forming and consistency: A hydraulic press offers the best combination of immense tonnage, repeatability, and operational efficiency for shaping and assembly.

- If your primary focus is bonding or forming with thermal requirements: A hot press provides the essential, precise control over both temperature and pressure needed for creating strong, permanent connections.

- If your primary focus is cost reduction and operational efficiency: The simple design, material savings, and lower tool wear associated with modern presses make them a sound long-term investment for any production line.

Understanding these core benefits allows you to select the precise press technology that will elevate your production quality, reliability, and efficiency.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Force & Tonnage | Applies immense, evenly distributed pressure | Shaping robust materials, high-force assembly |

| Consistency & Repeatability | Ensures identical results for quality control | Manufacturing uniform parts, sample preparation |

| Simplicity & Reliability | Fewer moving parts, reduced maintenance | Long-term cost savings, safer operation |

| Thermal Control (Hot Presses) | Precise heat and pressure for strong bonds | Electronics, composite materials, permanent connections |

| Economic Efficiency | Lowers material waste, mold costs, and operational complexity | Cost-effective production, increased ROI |

Ready to enhance your production with precision and reliability? At KINTEK, we specialize in high-quality lab equipment and consumables, including hydraulic and hot presses tailored to your specific needs. Whether you're in manufacturing, R&D, or materials testing, our presses deliver unmatched force control, consistency, and efficiency—helping you reduce costs and improve product quality. Contact us today to find the perfect press solution for your laboratory or production line!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual Lab Heat Press

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy