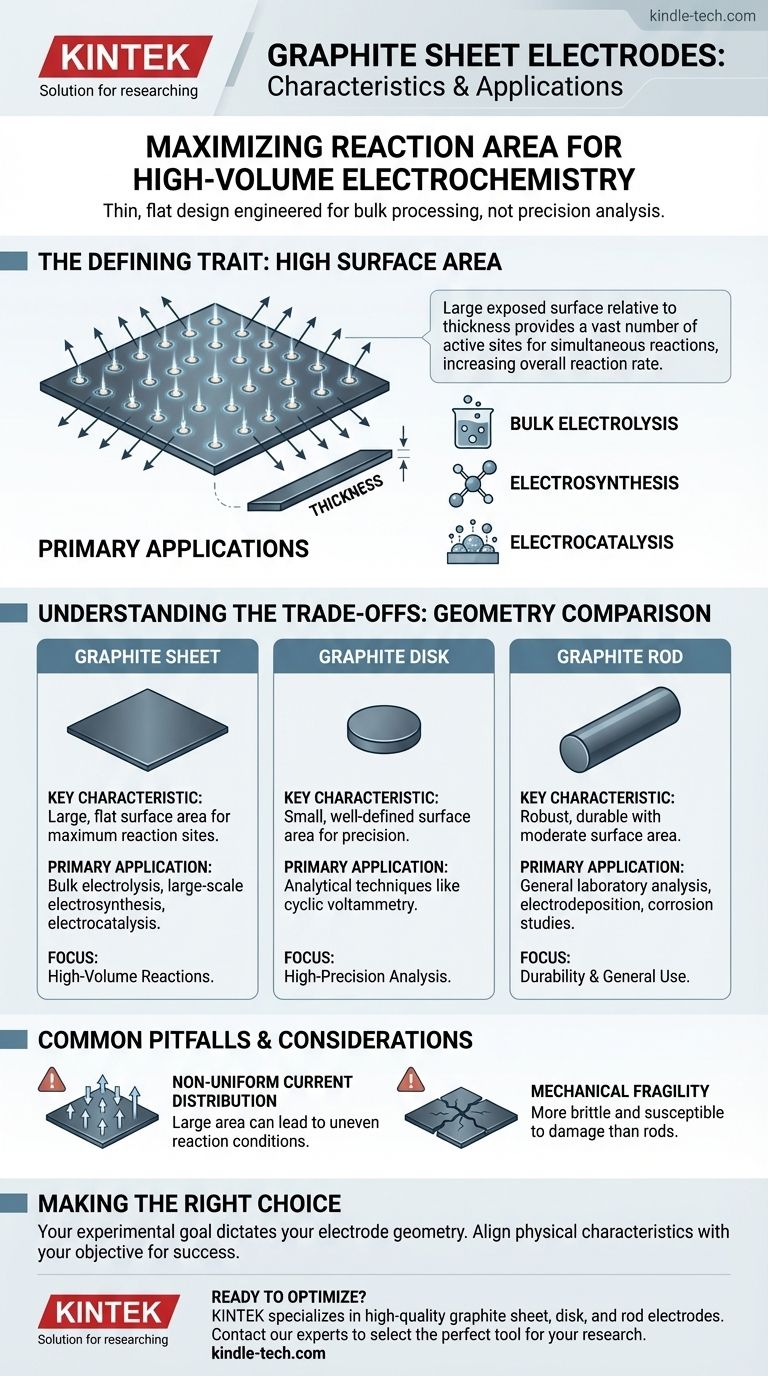

At its core, a graphite sheet electrode is a thin, flat electrode characterized by a very large surface area relative to its thickness. This specific geometry makes it the ideal choice for electrochemical experiments where maximizing the reaction area is the primary goal, such as in bulk electrolysis, large-scale electrosynthesis, and electrocatalysis.

The critical insight is that electrode geometry is not an aesthetic choice, but a functional one. A graphite sheet is engineered for high-volume processing, fundamentally distinguishing it from disk or rod electrodes designed for precision measurement or general use.

The Defining Trait: Maximizing Reaction Area

The unique value of a graphite sheet electrode stems directly from its form factor. Its design is a deliberate strategy to facilitate large-scale electrochemical reactions.

High Surface Area-to-Thickness Ratio

A sheet, by definition, maximizes the exposed surface while minimizing volume. This provides a vast number of active sites where electrochemical reactions can occur simultaneously.

Impact on Reaction Rate

For processes limited by surface area, a larger active area directly translates to a higher overall reaction rate. This allows for the efficient conversion of a larger quantity of reactants in a given amount of time.

Primary Applications

This characteristic makes sheet electrodes essential for applications focused on production or bulk conversion. This includes electrolysis, electrosynthesis (creating new chemical compounds), and electrocatalysis, where the sheet may support a catalyst material.

Understanding the Trade-offs: Sheet vs. Other Geometries

Choosing the correct electrode shape is crucial for obtaining meaningful results. The function of a sheet is best understood when compared to other common forms.

Graphite Sheet: For High-Volume Reactions

The sheet's large, flat surface is built for processing large volumes of solution. Its primary purpose is to drive a reaction to completion on a macro scale.

Graphite Disk: For High-Precision Analysis

In contrast, a graphite disk electrode has a small, well-defined circular surface. This controlled area is vital for high-precision analytical techniques like cyclic voltammetry, where the goal is to measure and understand reaction kinetics, not produce a product in bulk.

Graphite Rod: For Durability and General Use

A graphite rod electrode offers a balance of moderate surface area and high mechanical strength. Its simple, robust structure makes it a durable workhorse for general laboratory analysis, electrodeposition, and corrosion studies where extreme precision or massive surface area is not the main requirement.

Common Pitfalls and Considerations

While powerful, the sheet geometry is not universally optimal. Understanding its limitations is key to proper application.

Non-Uniform Current Distribution

The large surface area can sometimes lead to uneven current distribution across the electrode face. This can be problematic for experiments that require highly uniform reaction conditions.

Mechanical Fragility

Compared to a solid rod, a thin graphite sheet can be more brittle and susceptible to damage if not handled carefully. This is a practical consideration for setup and long-term use.

Making the Right Choice for Your Goal

Your experimental objective should dictate your choice of electrode. The geometry is a tool selected for a specific job.

- If your primary focus is bulk electrolysis or large-scale synthesis: The high surface area of a graphite sheet electrode is designed for this exact purpose.

- If your primary focus is precise analytical measurement (e.g., voltammetry): The small, controlled surface of a graphite disk electrode is necessary for accurate data.

- If your primary focus is general-purpose lab work or corrosion studies: The durability and simple form factor of a graphite rod electrode make it a reliable choice.

Ultimately, aligning the electrode's physical characteristics with your scientific goal is fundamental to successful electrochemical work.

Summary Table:

| Electrode Type | Key Characteristic | Primary Application |

|---|---|---|

| Graphite Sheet | Large, flat surface area for maximum reaction sites | Bulk electrolysis, large-scale electrosynthesis, electrocatalysis |

| Graphite Disk | Small, well-defined surface area for precision | Analytical techniques like cyclic voltammetry |

| Graphite Rod | Robust, durable with moderate surface area | General laboratory analysis, electrodeposition, corrosion studies |

Ready to optimize your electrochemical processes? The right electrode geometry is critical to your success. At KINTEK, we specialize in providing high-quality lab equipment, including graphite sheet, disk, and rod electrodes tailored for applications like bulk electrolysis and electrosynthesis. Our experts can help you select the perfect electrode to maximize reaction efficiency and achieve your experimental goals. Contact our team today to discuss your specific needs and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Gold Disc Electrode

People Also Ask

- What are the potential risks when using a graphite electrode in electrochemical tests? Avoid Decomposition and Contamination

- What are the properties of graphite rods? Leverage High Conductivity for Extreme Applications

- What technical advantages do carbon graphite electrodes offer for electroactive biofilms? Optimize Your Bio-Research

- What are the properties and applications of a graphite disk electrode? Precision Tools for Electroanalysis

- Why is a high-purity graphite rod preferred as a counter electrode? Ensure Uncontaminated Electrochemical Analysis