At their core, benchtop freeze dryers are characterized by their compact size, limited capacity, and focus on laboratory-scale applications. They are specifically engineered for research, development, and small-batch sample preservation, offering an accessible entry point into lyophilization technology without the significant footprint or cost of larger systems.

A benchtop freeze dryer is the ideal instrument for foundational research and sample preparation where flexibility and lab space are paramount. However, its inherent design creates a hard limit on sample volume and process scalability.

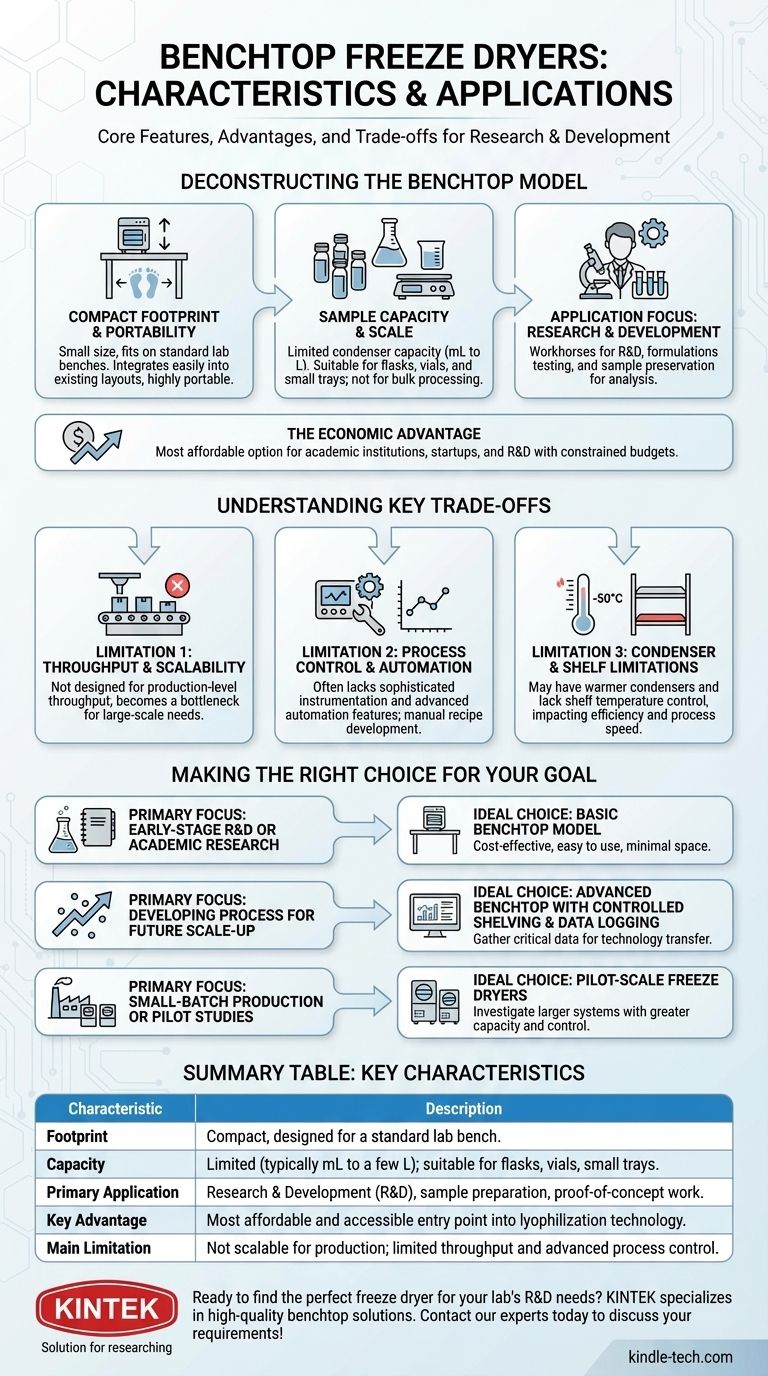

Deconstructing the Benchtop Model

To determine if a benchtop unit is right for your work, it is essential to understand its defining features and the context in which they operate. These characteristics are not arbitrary; they are the result of designing for a specific user and environment.

Compact Footprint and Portability

The most immediate characteristic is the small physical size. These units are designed to sit on a standard laboratory bench, conserving valuable floor space.

This design makes them easy to integrate into existing lab layouts. Some smaller models can even be moved between different labs, offering a degree of portability not possible with larger, stationary units.

Sample Capacity and Scale

Benchtop models are defined by a relatively small condenser capacity, typically ranging from a few hundred milliliters up to several liters. This directly limits the total amount of ice (and therefore water) that can be removed from your product in a single cycle.

In practical terms, this is suitable for drying samples in flasks, vials, or small trays. It is ideal for preserving cultures, preparing analytical samples, or developing early-stage formulations, but it is not built for bulk material processing.

Application Focus: Research and Development

These machines are the workhorses of R&D. Their primary purpose is to enable scientists and researchers to test formulations, preserve sensitive biological materials, or prepare samples for further analysis.

They provide a crucial capability for proof-of-concept work and foundational science where the quantity of material is secondary to the quality of the preservation.

The Economic Advantage

Compared to pilot-scale or production-scale freeze dryers, benchtop units represent the most affordable option. This lower capital investment makes the technology accessible to academic institutions, startups, and R&D departments with constrained budgets.

Understanding the Key Trade-offs

The advantages of a benchtop freeze dryer are directly linked to a series of critical trade-offs. Acknowledging these limitations is key to avoiding a mismatched investment.

Limitation 1: Throughput and Scalability

The small capacity is the most significant limitation. If your goal is to produce material for clinical trials or to sell a product, a benchtop unit will quickly become a bottleneck. It is not designed for production-level throughput.

Limitation 2: Process Control and Automation

While modern benchtop units offer good control, they often lack the sophisticated instrumentation and automation features of their larger counterparts. Recipe development may be more manual, and features like pressure rise tests for endpoint detection may be less refined or absent.

Limitation 3: Condenser and Shelf Limitations

The condenser's temperature and capacity dictate how efficiently water vapor is trapped. Smaller units may have warmer condensers (e.g., -50°C vs. -85°C), which can be insufficient for solvents with very low freezing points. Additionally, many basic models lack shelf temperature control, relying on ambient heat transfer, which makes the process slower and less repeatable.

Making the Right Choice for Your Goal

Selecting the correct freeze dryer is a matter of aligning the instrument's capabilities with your specific operational needs and future goals.

- If your primary focus is early-stage R&D or academic research: A benchtop model is the ideal choice for its cost-effectiveness, ease of use, and minimal space requirements.

- If your primary focus is developing a process for future scale-up: A more advanced benchtop unit with controlled shelving and data logging is necessary to gather the critical data required for successful technology transfer.

- If your primary focus is small-batch production or pilot studies: You have outgrown the benchtop category and should investigate pilot-scale freeze dryers that offer greater capacity and process control.

Understanding these core characteristics ensures you invest in a tool that accelerates your work rather than limits it.

Summary Table:

| Characteristic | Description |

|---|---|

| Footprint | Compact, designed for a standard lab bench. |

| Capacity | Limited (typically mL to a few L); suitable for flasks, vials, small trays. |

| Primary Application | Research & Development (R&D), sample preparation, proof-of-concept work. |

| Key Advantage | Most affordable and accessible entry point into lyophilization technology. |

| Main Limitation | Not scalable for production; limited throughput and advanced process control. |

Ready to find the perfect freeze dryer for your lab's R&D needs? KINTEK specializes in providing high-quality benchtop freeze dryers and lab equipment tailored for researchers. Whether you're preserving sensitive samples or developing new formulations, our solutions offer the reliability and performance you need. Contact our experts today to discuss how we can support your laboratory's specific requirements!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Small Injection Molding Machine for Lab Use

People Also Ask

- What is the freeze drying or lyophilisation process? A Guide to Gentle, High-Quality Dehydration

- What are the three phases of freeze drying? Mastering Lyophilization for Perfect Preservation

- What is the eutectic point in lyophilization? Master the Critical Temperature for Success

- What types of pharmaceutical products are commonly produced using freeze drying technology? Essential for Vaccines & Biologics

- Why are freeze-dried drugs advantageous for clinical trials? Ensure Stability and Simplify Logistics