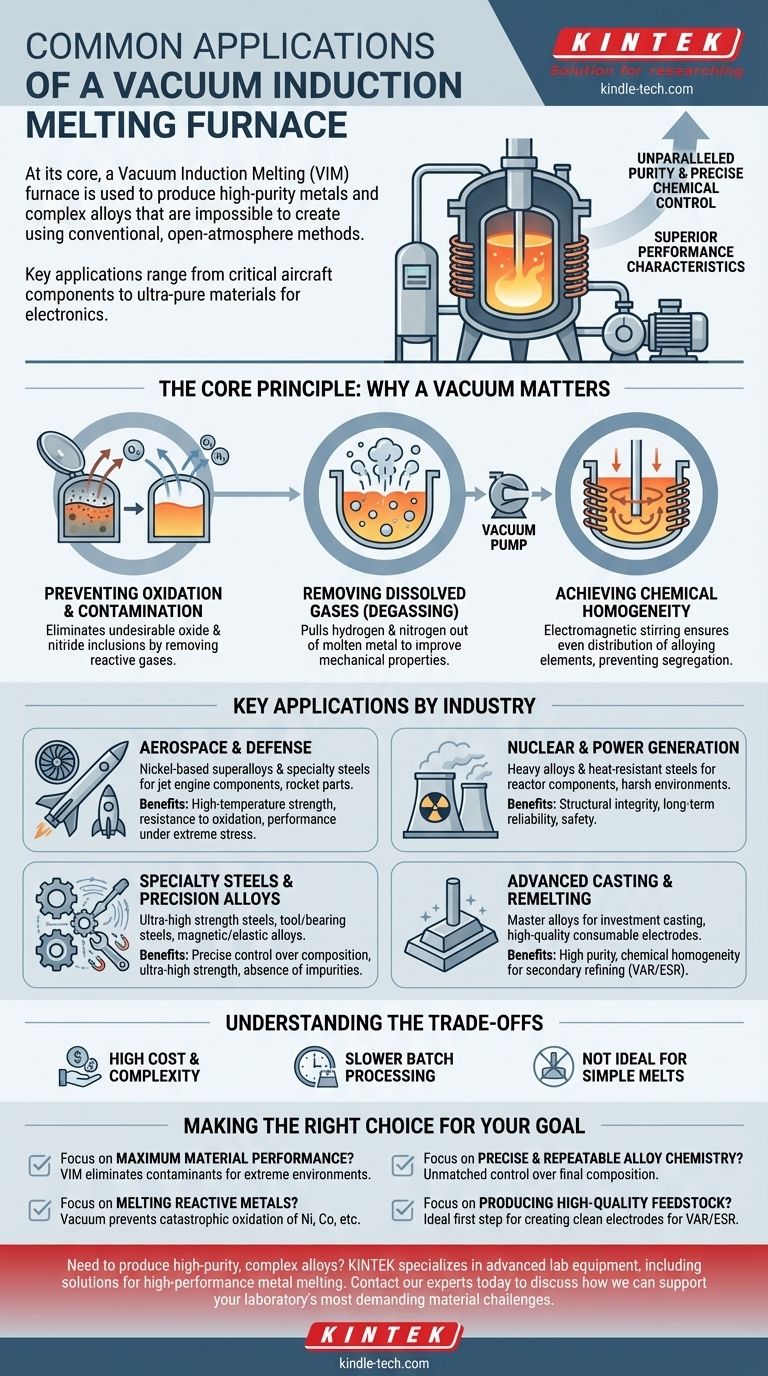

At its core, a vacuum induction melting (VIM) furnace is used to produce high-purity metals and complex alloys that are impossible to create using conventional, open-atmosphere methods. Its common applications range from casting critical aircraft components and specialty steels to refining the ultra-pure materials required by the electronics and nuclear industries.

The essential purpose of a vacuum induction furnace isn't just to melt metal; it's to achieve unparalleled purity and precise chemical control. The vacuum environment is the key, eliminating atmospheric contamination to produce materials with superior performance characteristics.

The Core Principle: Why a Vacuum Matters

To understand the applications of a VIM furnace, you must first understand the fundamental problem it solves: contamination. Many high-performance metals are highly reactive with gases in the air, especially oxygen.

Preventing Oxidation and Contamination

When advanced alloys are melted in the open air, they react with oxygen and nitrogen. This forms undesirable oxide and nitride inclusions, which compromise the material's strength, durability, and overall integrity.

A VIM furnace operates under a high vacuum, removing these reactive gases. This prevents the formation of impurities, resulting in a cleaner, higher-quality final product.

Removing Dissolved Gases

The vacuum environment also performs a critical refining function known as degassing. It pulls dissolved gases, like hydrogen and nitrogen, out of the molten metal.

This process significantly improves the mechanical properties of the material, preventing issues like hydrogen embrittlement.

Achieving Chemical Homogeneity

VIM furnaces use electromagnetic induction to both heat and stir the molten metal. This electromagnetic stirring is crucial for ensuring all alloying elements are distributed perfectly evenly throughout the melt.

The result is a completely homogenous alloy with consistent properties, free from the segregation that can plague other melting methods.

Key Applications by Industry

The unique capabilities of VIM furnaces make them indispensable in industries where material failure is not an option. They are used to produce materials that must perform under extreme conditions.

Aerospace and Defense

This is a primary application sector. VIM furnaces are used to produce nickel-based superalloys and specialty steels for jet engine turbine blades, rocket components, and other critical aerospace parts.

These components must withstand extreme temperatures and mechanical stress, and the purity achieved in a VIM furnace is essential for this performance.

Nuclear and Power Generation

The nuclear and power generation industries rely on heavy alloys and heat-resistant steels for components that operate in harsh, corrosive environments.

A VIM furnace ensures these materials have the purity and structural integrity needed for safety and long-term reliability.

Specialty Steels and Precision Alloys

VIM technology is fundamental to producing a wide range of advanced materials, including:

- Ultra-high strength steels

- Tool and bearing steels

- Magnetic and elastic alloys

In each case, precise control over the alloy's composition and the absence of impurities are what create the desired material properties.

Advanced Casting and Remelting

VIM furnaces are often the first step in a larger manufacturing process. They are used to create master alloys for precision investment casting and to produce high-quality consumable electrodes.

These electrodes are then used in secondary refining processes like Vacuum Arc Remelting (VAR) or Electroslag Remelting (ESR) to achieve even higher levels of purity.

Understanding the Trade-offs

While powerful, a VIM furnace is a specialized tool with inherent trade-offs that make it unsuitable for all applications.

High Cost and Complexity

These are complex systems involving high-power electronics, robust vacuum pumps, and sophisticated controls. This results in significant capital investment and higher operating costs compared to conventional furnaces.

Slower Batch Processing

VIM furnaces operate on a batch-by-batch basis. This is ideal for quality control and producing specialized alloys, but it results in lower throughput than continuous melting processes used for high-volume commodity metals.

Not Ideal for Simple Melts

For applications where material purity is not the primary concern—such as melting basic cast iron or simple steels—a VIM furnace is unnecessary overkill. A standard induction or arc furnace is far more cost-effective.

Making the Right Choice for Your Goal

Selecting a VIM furnace is a decision driven entirely by the final material requirements. Its value is directly tied to the need for purity and precise chemical control.

- If your primary focus is maximum material performance: A VIM furnace is the definitive choice for eliminating contaminants and producing alloys that can withstand extreme environments.

- If your primary focus is precise and repeatable alloy chemistry: The controlled vacuum environment and electromagnetic stirring provide unmatched control over the final composition.

- If your primary focus is melting reactive metals: For alloys based on nickel, cobalt, or other reactive elements, the vacuum is non-negotiable to prevent catastrophic oxidation.

- If your primary focus is producing high-quality feedstock for secondary refining: A VIM furnace is the ideal first step for creating clean, homogenous electrodes for VAR or ESR processes.

Ultimately, a vacuum induction furnace is chosen when the integrity and performance of the final material cannot be compromised.

Summary Table:

| Industry | Key Applications | Key Material Benefits |

|---|---|---|

| Aerospace & Defense | Jet engine turbine blades, rocket components | High-temperature strength, resistance to oxidation |

| Nuclear & Power Generation | Reactor components, heat-resistant parts | Structural integrity, long-term reliability in harsh environments |

| Specialty Steels & Alloys | Tool steels, bearing steels, magnetic alloys | Ultra-high strength, precise mechanical properties |

| Advanced Casting | Master alloys, consumable electrodes for VAR/ESR | High purity, chemical homogeneity for secondary refining |

Need to produce high-purity, complex alloys? KINTEK specializes in advanced lab equipment, including solutions for high-performance metal melting. Our expertise can help you achieve the precise chemical control and material purity required for aerospace, nuclear, and specialty steel applications. Contact our experts today to discuss how we can support your laboratory's most demanding material challenges.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are the disadvantages of core type induction heating? Poor Adaptability for Complex Parts

- How does heating occur in induction heating? Unlock the Power of Internal, Non-Contact Heat

- What is the difference between VAR and ESR steel? Choose the Right Process for Superior Performance

- What is the basic principle of induction furnace? Achieve Fast, Clean Metal Melting

- What is the hardest metal to melt? Tungsten Leads, But Advanced Materials Go Further

- What is the power factor of a coreless induction furnace? Achieve High Efficiency and Avoid Costly Penalties

- What is the difference between resistance heating and induction heating? Choose the Right Method for Your Needs

- What is the power of induction furnace? Unlock Precise Control and Efficiency for Your Lab