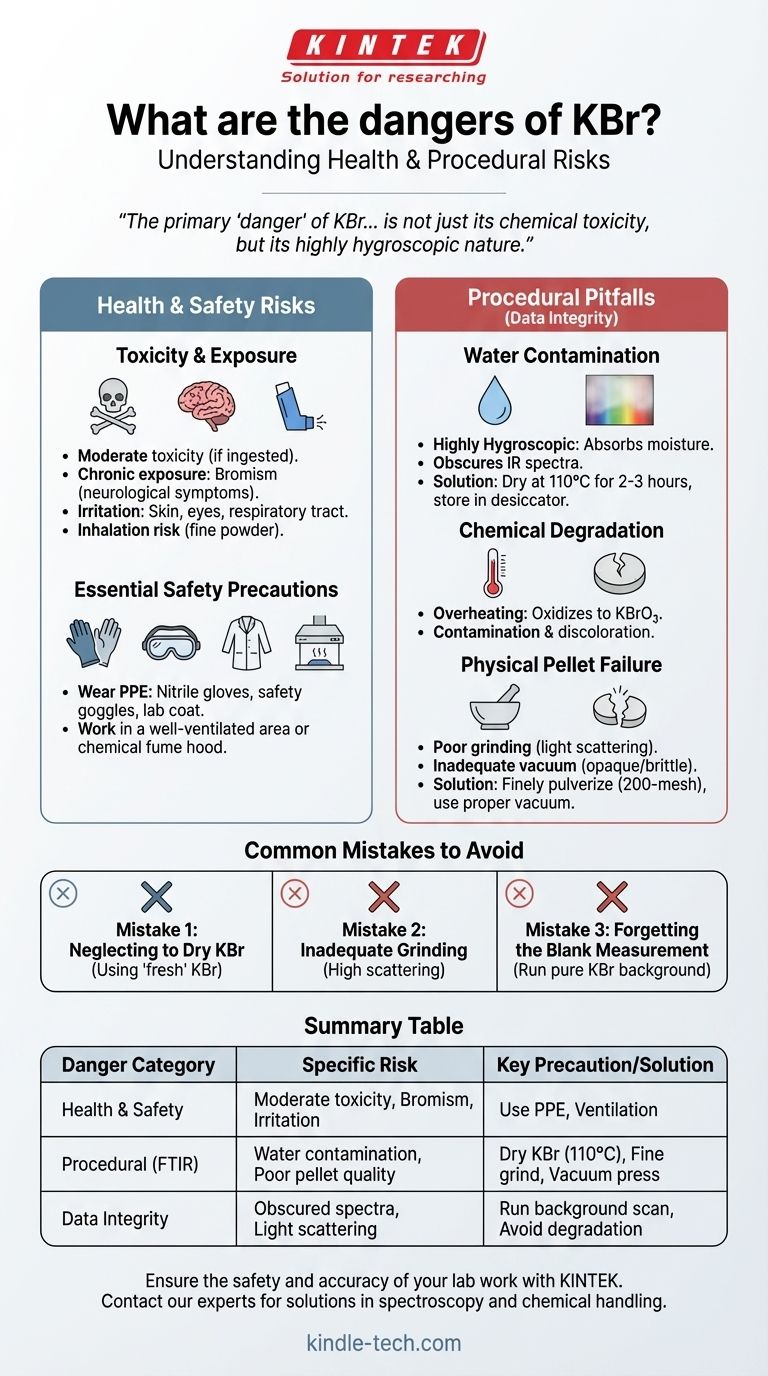

At its core, the dangers of potassium bromide (KBr) fall into two distinct categories. The first are the direct health risks associated with its moderate toxicity and potential for irritation. The second are the procedural risks, particularly in sensitive applications like FTIR spectroscopy, where improper handling can compromise the integrity of your sample and the accuracy of your results.

The primary "danger" of KBr in a laboratory setting is not just its chemical toxicity, but its highly hygroscopic nature. Failure to control moisture leads to contaminated samples and invalid analytical data, representing a significant risk to the success of your work.

Understanding the Health & Safety Risks

While often used in labs, KBr is not benign and requires standard chemical handling precautions. Understanding its specific health profile is the first step to safe handling.

Toxicity and Exposure

KBr is considered moderately toxic if ingested. Acute, large-dose exposure can lead to symptoms like nausea, vomiting, and central nervous system depression.

Chronic or repeated exposure is a more significant concern, as it can lead to a condition known as bromism. This results from the accumulation of bromide ions in the body, which can cause a range of neurological symptoms, including confusion, irritability, tremors, and memory loss.

Direct contact can also cause irritation to the skin, eyes, and respiratory tract. Fine KBr powder is easily inhaled, making ventilation crucial.

Essential Safety Precautions

Given these risks, proper personal protective equipment (PPE) is non-negotiable when working with KBr.

Always wear nitrile gloves, safety goggles, and a lab coat. When handling KBr powder, especially during grinding or weighing, work in a well-ventilated area or under a chemical fume hood to prevent inhalation.

Procedural Pitfalls: The Dangers to Your Data

In the context of preparing KBr pellets for FTIR spectroscopy, the "dangers" are factors that threaten the quality and validity of your analysis. These are often subtle and relate directly to the chemical properties of KBr.

The Problem of Water Contamination

KBr is extremely hygroscopic, meaning it readily absorbs moisture from the atmosphere. This is the single greatest procedural risk.

Water has strong absorption bands in the infrared spectrum, which will obscure the spectral features of your actual sample. To prevent this, KBr must be thoroughly dried, typically at 110 °C for 2-3 hours, and stored in a desiccator.

Risk of Chemical Degradation

Heating KBr too rapidly or at excessively high temperatures can cause it to oxidize into potassium bromate (KBrO₃).

This degradation not only contaminates your pellet but can also cause discoloration, altering the optical properties of the pellet and interfering with your measurement.

Physical Pellet Failure

The physical quality of the KBr pellet is paramount for good data. Two factors are critical.

First, the KBr powder must be finely pulverized (to a 200-mesh particle size) to minimize light scattering, which causes sloping baselines and reduces signal quality. Second, an inadequate vacuum during pressing will trap air, resulting in an opaque or brittle pellet that breaks easily.

Common Mistakes to Avoid

These procedural dangers manifest as common handling mistakes. Being aware of them is key to generating reliable data.

Mistake 1: Neglecting to Dry KBr

Assuming "fresh" KBr from a container is dry enough is a frequent error. Always perform the drying step immediately before use to remove adsorbed atmospheric moisture.

Mistake 2: Inadequate Grinding

Insufficient grinding of the KBr and sample mixture is a primary cause of poor-quality spectra. This leads to high scattering and can make it impossible to interpret the results.

Mistake 3: Forgetting the Blank Measurement

Many users forget to run a background spectrum using a pure KBr pellet. This step is essential to correct for any residual moisture, scattering effects, or instrument variations, ensuring the final spectrum shows only your sample.

Making the Right Choice for Your Goal

Your approach to handling KBr should be dictated by your primary objective, whether it's personal safety or analytical precision.

- If your primary focus is personal safety: Always use gloves and eye protection, and handle KBr powder in a well-ventilated space to prevent inhalation and direct contact.

- If your primary focus is accurate FTIR data: Your main goal is to eliminate water by rigorously drying the KBr, grinding it finely, and running a proper background scan.

- If your primary focus is efficiency: Following these preparation steps correctly the first time saves hours of troubleshooting and repeating failed experiments.

Ultimately, mastering the proper handling of KBr ensures both your personal safety and the integrity of your scientific results.

Summary Table:

| Danger Category | Specific Risk | Key Precaution/Solution |

|---|---|---|

| Health & Safety | Moderate toxicity (bromism), skin/eye irritation, inhalation risk | Use PPE (gloves, goggles), work in a fume hood, ensure ventilation |

| Procedural (FTIR) | Water contamination from hygroscopic nature, poor pellet quality | Dry KBr at 110°C, grind to 200-mesh, use proper vacuum pressing |

| Data Integrity | Obscured IR spectra, light scattering, inaccurate results | Run a pure KBr background scan, ensure fine grinding, avoid degradation |

Ensure the safety and accuracy of your lab work with KINTEK.

Navigating the dangers of potassium bromide (KBr) requires precision and the right equipment. KINTEK specializes in high-quality laboratory equipment and consumables designed to mitigate these risks. From reliable drying ovens and desiccators for moisture-sensitive materials to precision presses for perfect KBr pellets, our products help you achieve clear, uncontaminated FTIR results while protecting your team's health.

Don't let improper handling compromise your research. Contact our experts today via our Contact Form to find the perfect solutions for your laboratory's specific needs in spectroscopy and chemical handling.

Visual Guide

Related Products

- kbr pellet press 2t

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- What temperature should a furnace run at? From Home Comfort to Industrial Processes

- What are the advantages and disadvantages in metal fabrication? Unlock Unmatched Strength & Design Flexibility

- What is used to heat treat steel? Master the Tools for Precise Metallurgical Control

- How is heat transferred in a furnace? Master Radiation, Convection & Conduction

- Why is temperature excursion alarming important in ultra-low freezers? Protect Your Valuable Samples from Catastrophic Loss

- Can you reheat a brazed joint? A guide to repair, disassembly, and post-braze processes

- How does Spark Plasma Sintering (SPS) heating differ from Cold Sintering (CSP)? Thermal vs. Chemical Consolidation

- What is a temperature control system for digital applications? The Key to Reliable Electronics Performance