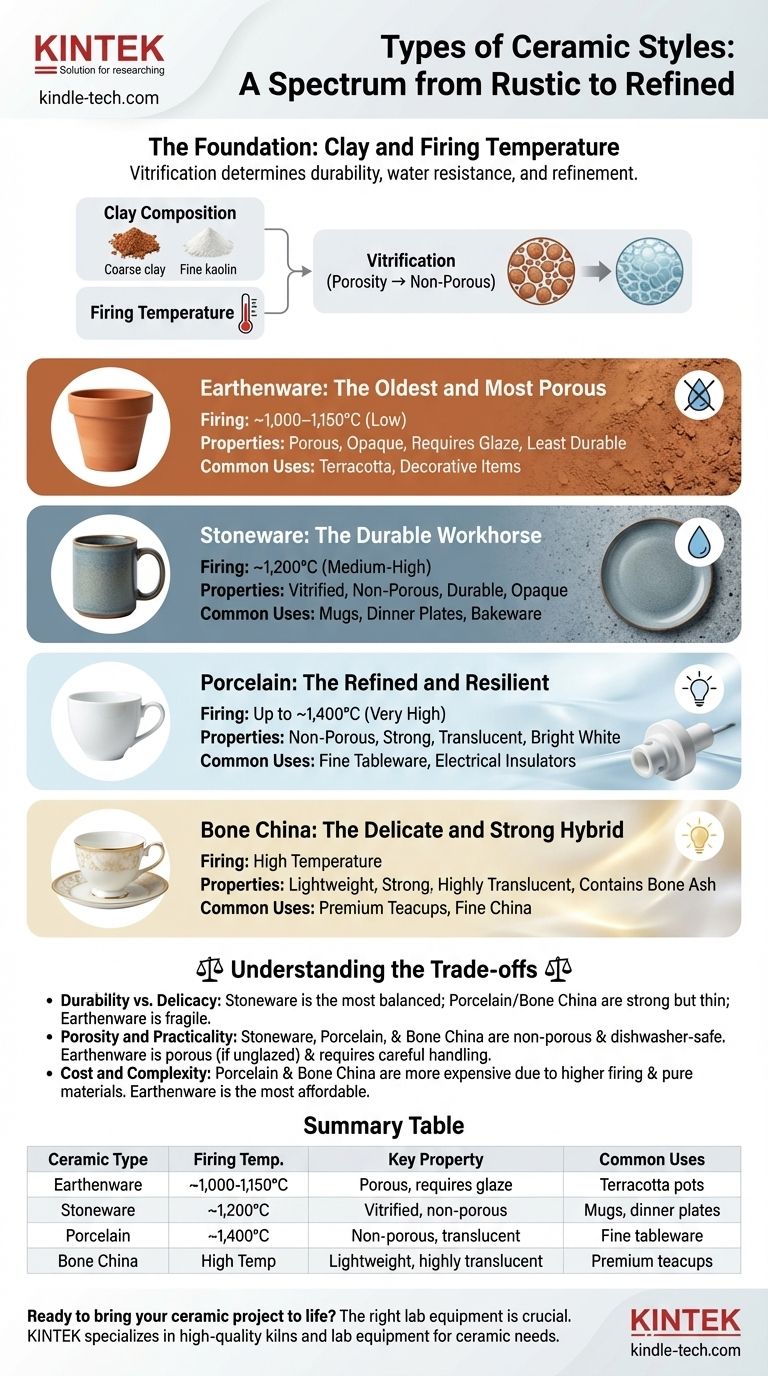

When we talk about ceramic styles, we are fundamentally discussing four primary categories determined by the clay composition and the heat of the firing process. The most common types you will encounter are earthenware, stoneware, porcelain, and bone china. Each possesses distinct properties that make it suitable for different applications, from a rustic flowerpot to a delicate teacup.

The "style" of a ceramic piece is not merely an aesthetic choice; it is a direct result of its material science. The key difference is vitrification—the process of turning porous clay into a non-porous, glass-like state—which dictates the object's durability, water resistance, and refinement.

The Foundation: Clay and Firing Temperature

To understand the different types of ceramics, you must first understand the two core variables that define them: the clay used and the temperature it's fired at. These factors work together to determine the final product's strength, density, and porosity.

The Role of Clay Composition

Ceramics begin as clay, but not all clay is the same. Different clays contain varying amounts of minerals, silica, and impurities.

Earthenware clays are common and fire at low temperatures, while porcelain is made from a more refined, pure white clay called kaolin, which requires much higher temperatures.

The Impact of Firing Temperature

Firing in a kiln transforms the clay. The higher the temperature, the more the clay particles melt and fuse together in a process called vitrification.

A fully vitrified ceramic is dense, non-porous (it won't absorb water), and much stronger. A low-fired ceramic remains porous and is significantly less durable.

The Four Primary Ceramic Types Explained

Each ceramic type represents a point on a spectrum from porous and rustic to dense and refined.

Earthenware: The Oldest and Most Porous

Earthenware is fired at the lowest temperatures (approx. 1,000-1,150°C or 1,830-2,100°F). Because it doesn't fully vitrify, it remains porous and must be coated in a glaze to be waterproof.

It is often rustic and opaque, with terracotta being a well-known example. It is the least durable of the four types.

Stoneware: The Durable Workhorse

Stoneware is fired at a medium-high temperature (approx. 1,200°C or 2,190°F), hot enough for it to become vitrified and non-porous. This makes it exceptionally durable and ideal for everyday use.

It is stronger than earthenware, typically opaque, and widely used for mugs, dinner plates, and bakeware.

Porcelain: The Refined and Resilient

Porcelain is made from fine kaolin clay and fired at very high temperatures (up to 1,400°C or 2,550°F). This process makes it extremely hard, dense, and non-porous.

It is known for its strength, translucence (light can pass through it), and bright white color. Beyond fine tableware, its properties make it essential for technical ceramics like electrical insulators.

Bone China: The Delicate and Strong Hybrid

Bone china is a specific type of porcelain that includes bone ash as a key ingredient. This addition creates a unique material that is incredibly strong yet surprisingly lightweight.

It is renowned for its high level of translucence and delicate appearance, making it a premium material for high-end "fine china" and teacups.

Understanding the Trade-offs

Choosing a ceramic type involves balancing durability, appearance, and practicality. No single type is universally "best"; it depends entirely on the intended use.

Durability vs. Delicacy

While porcelain and bone china are technically stronger and more chip-resistant than earthenware, their thinness can make them feel more delicate. Stoneware offers the best practical balance of thickness and durability for heavy daily use. Earthenware is the most fragile and prone to chipping.

Porosity and Practicality

An unglazed earthenware pot will absorb water, making it unsuitable for holding food or liquids. Properly glazed earthenware is functional, but if the glaze chips, the porous body underneath is exposed.

Stoneware and porcelain are non-porous even without a glaze, making them fully waterproof, dishwasher-safe, and more hygienic for food.

Cost and Complexity

The higher the firing temperature and the purer the clay, the more complex and expensive the manufacturing process. This is why porcelain and bone china are generally more costly than stoneware, with earthenware being the most affordable.

Choosing the Right Ceramic for Your Needs

Your decision should be guided by the final application of the piece.

- If your primary focus is everyday durability: Choose stoneware for its excellent balance of strength, practicality for dishwashers and microwaves, and affordability.

- If your primary focus is rustic appeal or hobbyist pottery: Earthenware is an accessible and classic choice, but be mindful of its porous nature and lower durability.

- If your primary focus is elegance and formal dining: Porcelain or bone china offers unmatched refinement, strength, and a delicate, translucent quality.

Understanding the material science behind each ceramic type empowers you to select the perfect object for any purpose.

Summary Table:

| Ceramic Type | Firing Temperature | Key Property | Common Uses |

|---|---|---|---|

| Earthenware | ~1,000-1,150°C | Porous, requires glaze | Terracotta pots, decorative items |

| Stoneware | ~1,200°C | Vitrified, non-porous, durable | Everyday mugs, dinner plates, bakeware |

| Porcelain | Up to ~1,400°C | Non-porous, strong, translucent | Fine tableware, electrical insulators |

| Bone China | High temperature | Lightweight, strong, highly translucent | Premium teacups, fine china |

Ready to bring your ceramic project to life? The right lab equipment is crucial for precise firing and consistent results. KINTEK specializes in high-quality kilns and lab equipment for ceramic artists, hobbyists, and industrial manufacturers. Whether you're working with delicate porcelain or durable stoneware, our solutions ensure optimal temperature control and reliability. Contact our experts today to find the perfect equipment for your ceramic needs!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

People Also Ask

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- Is silicon carbide better than ceramic? Discover the Superior Technical Ceramic for Your Application

- What is the resistivity of silicon carbide? It's a tunable property from <0.1 ohm-cm to highly resistive.

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection

- What is the strongest ceramics? Silicon Carbide Leads in Hardness & Thermal Strength