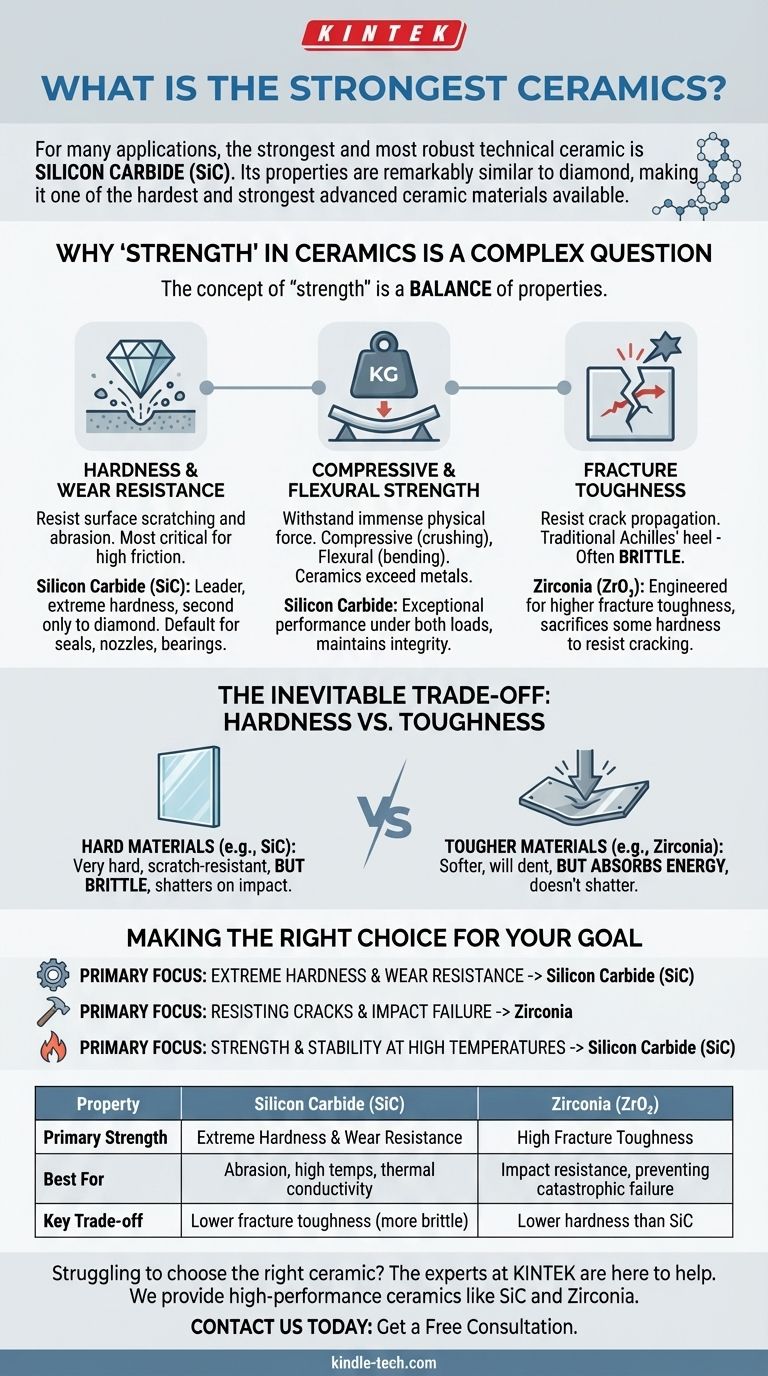

For many applications, the strongest and most robust technical ceramic is silicon carbide (SiC). Its properties are remarkably similar to diamond, making it one of the hardest and strongest advanced ceramic materials available. Silicon carbide combines this strength with exceptional thermal conductivity and chemical resistance, positioning it as a leading choice for the most demanding environments.

The concept of "strength" in ceramics is not a single value but a balance of properties. The "strongest" ceramic for your application depends entirely on whether the primary challenge is wear, load, impact, or high temperature.

Why 'Strength' in Ceramics is a Complex Question

The term "strongest" can be misleading when evaluating technical ceramics. An engineer must dissect the specific stresses the component will face. A material that excels in one area may be unsuitable in another.

Hardness and Wear Resistance

Hardness is a material's ability to resist surface scratching and abrasion. For applications involving high friction or contact with abrasive particles, this is the most critical form of strength.

Silicon carbide (SiC) is a leader in this category. Its extreme hardness, second only to materials like diamond, makes it the default choice for components like pump seals, nozzles, and bearings that must endure constant wear.

Compressive and Flexural Strength

This is what many people mean by "strength"—the ability to withstand immense physical force. Compressive strength measures resistance to being crushed, while flexural strength measures resistance to bending.

Technical ceramics as a class have extraordinarily high compressive strength, far exceeding metals. Silicon carbide again demonstrates exceptional performance under both compressive and bending loads, maintaining its integrity where other materials would deform or break.

Fracture Toughness

Fracture toughness is a material's ability to resist the propagation of a crack. This is the traditional Achilles' heel of ceramics; they are often brittle.

While a ceramic like silicon carbide is incredibly strong, a pre-existing flaw or a sharp impact can lead to catastrophic failure. Other ceramics, like zirconia, are specifically engineered to have higher fracture toughness, sacrificing some hardness to gain resistance to cracking.

The Inevitable Trade-off: Hardness vs. Toughness

Understanding the balance between hardness and toughness is essential for successful material selection. Choosing the wrong property to optimize can lead to premature component failure.

The Brittleness of Hard Materials

There is often an inverse relationship between hardness and fracture toughness. Materials with extremely rigid atomic bonds, which make them very hard, do not have mechanisms to absorb energy and stop a crack from spreading.

Think of it as the difference between a glass pane and a sheet of metal. The glass is very hard and scratch-resistant but shatters on impact. The metal is softer and will dent, but it won't shatter because it can deform and absorb the energy.

When to Prioritize Toughness

If your component may experience sudden impacts, thermal shock, or high-stress concentrations around sharp corners, prioritizing fracture toughness over absolute hardness is critical.

In these cases, a material like zirconia might be a better choice than silicon carbide, even though it is not as hard or strong in a traditional sense. It is more "durable" in an environment with unpredictable stresses.

Making the Right Choice for Your Goal

To select the correct material, you must align its dominant properties with the primary challenge of your application.

- If your primary focus is extreme hardness and wear resistance: Silicon carbide is your leading candidate due to its diamond-like surface properties.

- If your primary focus is resisting cracks and catastrophic failure from impact: You should investigate tougher ceramics engineered specifically for high fracture toughness, such as zirconia.

- If your primary focus is strength and stability at high temperatures: Silicon carbide is an excellent choice due to its low thermal expansion and ability to maintain strength when heated.

Understanding these critical distinctions is the key to leveraging the immense power of advanced ceramics in your design.

Summary Table:

| Property | Silicon Carbide (SiC) | Zirconia (ZrO₂) |

|---|---|---|

| Primary Strength | Extreme Hardness & Wear Resistance | High Fracture Toughness |

| Best For | Abrasion, high temperatures, thermal conductivity | Impact resistance, preventing catastrophic failure |

| Key Trade-off | Lower fracture toughness (more brittle) | Lower hardness than SiC |

Struggling to choose the right ceramic for your application's unique strength requirements? The experts at KINTEK are here to help. We specialize in providing advanced lab equipment and consumables, including high-performance ceramics like silicon carbide and zirconia. Our team can guide you to the optimal material based on your specific needs for wear resistance, impact tolerance, or high-temperature stability.

Contact us today to ensure your project benefits from the strongest possible solution.

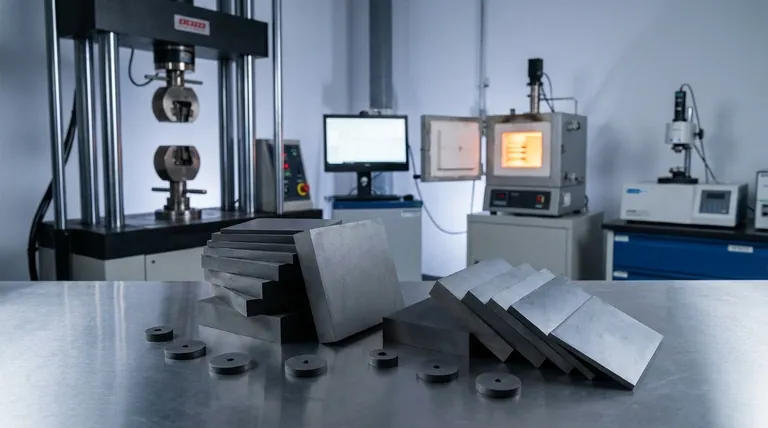

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- Why are alumina insulation discs used as sample supports in CCPN? Ensure Arcing-Free, Uniform Plasma Nitriding

- What happens to a ceramic material when it is sintered? The Transformation from Powder to Dense Solid

- What is the primary purpose of using zirconia coatings in W-Cu infiltration? Ensure Dense, Void-Free Composites

- How hot can you heat ceramic? From Pottery to 2700°C with Advanced Materials

- What is pressureless sintered silicon carbide? A Guide to High-Performance Ceramics

- What are the advantages of ceramic sintering? Achieve Dense, High-Performance Ceramic Parts

- What types of ceramics are used in sintering? Expert Guide to Advanced Materials and Forming

- How much temperature can porcelain withstand? Unlock Its True Heat Resistance & Avoid Thermal Shock