In essence, deposition coatings are broadly categorized by their material composition—primarily as metallic, ceramic, and organic layers. These functional materials are applied as thin films in a vacuum environment to fundamentally enhance a substrate's surface properties, such as hardness, wear resistance, corrosion protection, and thermal performance.

The choice of a deposition coating is not about finding a single "best" material. It is about matching a specific coating's unique properties—like the exceptional hardness of ceramics or the conductivity of metals—to the precise performance demands of your application.

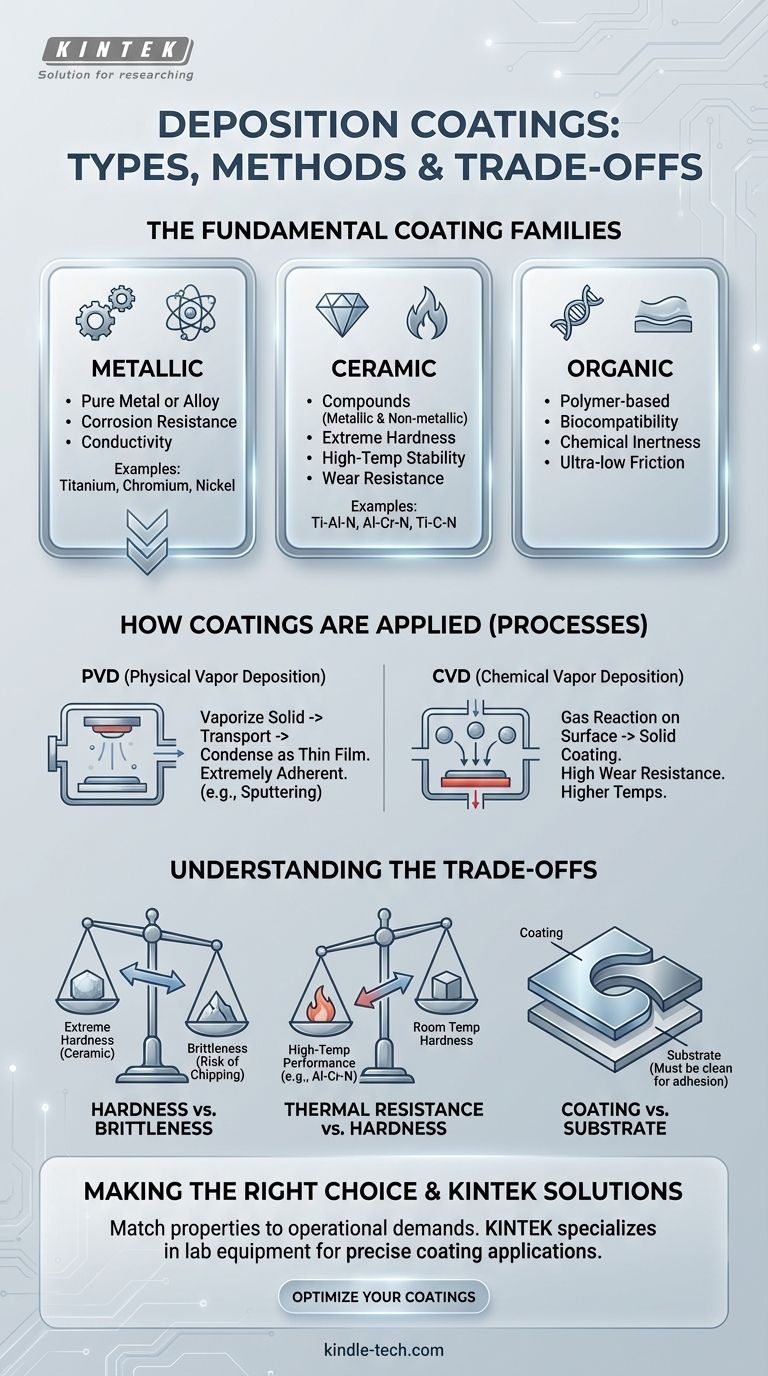

The Fundamental Coating Families

To understand deposition coatings, we must first classify them by their core material. Each family offers a distinct profile of strengths tailored to different operational challenges.

Metallic Coatings

Metallic coatings consist of a thin layer of a pure metal or an alloy. Common examples include titanium, chromium, nickel, copper, and cadmium.

These are often selected for their inherent metallic properties. They can provide excellent corrosion resistance, improve surface conductivity, or serve as a ductile, protective barrier.

Ceramic Coatings

Ceramic coatings are compounds of metallic and non-metallic elements. These are known for their exceptional hardness, high-temperature stability, and resistance to wear and corrosion.

Prominent examples include Titanium Aluminum Nitride (Ti-Al-N), which significantly increases hardness and wear resistance while reducing friction. Aluminum Chromium Nitride (Al-Cr-N) is valued for its superior thermal resistance, making it ideal for high-speed cutting tools.

Other specialized ceramics like Titanium Carbonitride (Ti-C-N) offer a unique solid solution of Titanium Carbide (TiC) and Titanium Nitride (TiN), providing a powerful combination of hardness and toughness.

Organic Coatings

While less common in high-wear industrial applications, organic coatings are also applied via deposition processes. These polymer-based films can be engineered for specialized properties like biocompatibility, chemical inertness, or creating ultra-low-friction surfaces.

How Coatings Are Applied: A Note on Process

It is critical to distinguish the coating material from the application method. The references mention sputtering, which is a method, not a type of coating. The method belongs to a larger family of processes called Physical Vapor Deposition.

Physical Vapor Deposition (PVD)

PVD encompasses a set of vacuum deposition techniques where a material is transformed into a vapor, transported across a vacuum chamber, and condensed onto a substrate as a thin film.

Methods like sputtering (including DC, RF, and magnetron sputtering) fall under this category. In PVD, the coating material starts in a solid form before being vaporized, resulting in an extremely adherent and high-purity film.

Chemical Vapor Deposition (CVD)

CVD is the other major deposition method. In this process, the substrate is exposed to volatile precursor gases within a reaction chamber. These gases decompose or react on the substrate's surface, forming the desired solid coating. CVD is often used for thick, highly wear-resistant coatings but typically requires higher temperatures than PVD.

Understanding the Trade-offs

Selecting a coating requires balancing competing properties. No single solution is perfect for every scenario, and understanding the trade-offs is key to making an informed decision.

Hardness vs. Brittleness

Extremely hard ceramic coatings, while excellent for resisting abrasive wear, can sometimes be more brittle than their metallic counterparts. The choice often involves finding a balance between a coating that won't wear down and one that won't chip or fracture under impact.

Thermal Resistance vs. Hardness

A coating's properties can change dramatically with temperature. For example, Al-Cr-N maintains its integrity and performance at high temperatures better than many other coatings, making it the superior choice for applications generating significant heat, even if another coating might be harder at room temperature.

Coating vs. Substrate

The final performance of a coated part is a function of both the coating and the substrate material. A coating is only as good as its adhesion. The substrate must be properly cleaned and prepared to ensure the "extremely adherent" bond that deposition processes are known for.

Making the Right Choice for Your Application

To select the appropriate coating, you must first define your primary operational challenge. Use the following as a guide.

- If your primary focus is extreme wear resistance and hardness: Consider advanced ceramic coatings like Titanium Aluminum Nitride (Ti-Al-N) or Titanium Carbonitride (Ti-C-N) for their superior durability.

- If your primary focus is high-temperature performance: Prioritize a coating with high thermal stability, such as Aluminum Chromium Nitride (Al-Cr-N), especially for high-speed machining or hot-working tools.

- If your primary focus is corrosion resistance or electrical conductivity: A pure metallic coating like titanium, nickel, or chromium may provide the most direct and effective solution.

Ultimately, the most effective coating is an extension of the component itself, precisely engineered to overcome its specific environmental and operational limits.

Summary Table:

| Coating Type | Key Properties | Common Applications |

|---|---|---|

| Metallic | Corrosion resistance, electrical conductivity | Aerospace components, electronic parts |

| Ceramic | Extreme hardness, high-temperature stability | Cutting tools, industrial machinery |

| Organic | Biocompatibility, chemical inertness | Medical devices, specialized surfaces |

Ready to optimize your components with the right deposition coating? At KINTEK, we specialize in lab equipment and consumables for precise coating applications. Whether you need durable ceramic coatings for high-wear tools or conductive metallic layers for electronics, our solutions are tailored to meet your laboratory's unique demands. Contact us today to discuss how our expertise can enhance your project's performance and longevity!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication