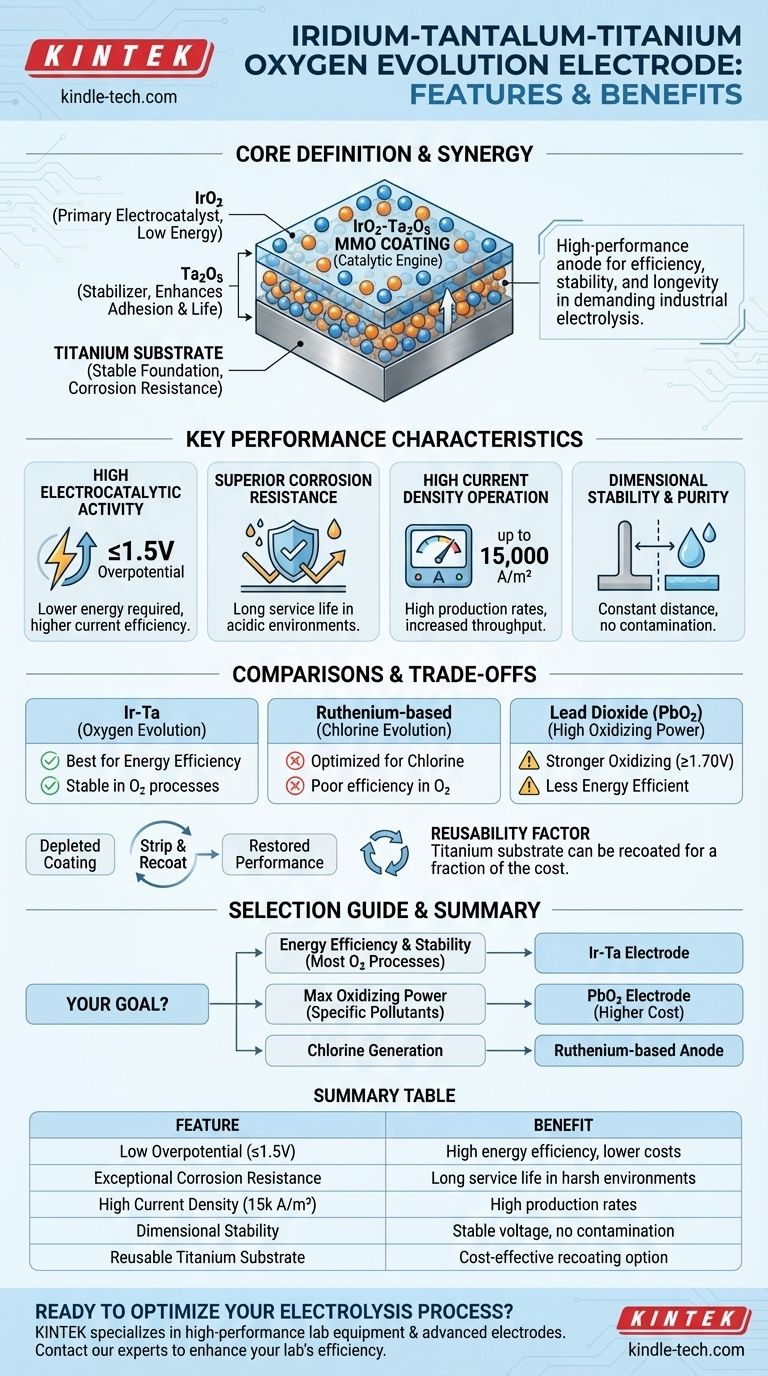

At its core, the Iridium-Tantalum-Titanium Oxygen Evolution Electrode is a high-performance anode designed for efficiency, stability, and longevity in demanding industrial electrolysis. Its key features include exceptional corrosion resistance, high electrocatalytic activity for oxygen evolution, and the ability to operate at high current densities, all built upon a reusable titanium substrate.

This electrode represents a critical balance between performance and durability. Its design solves the common problems of anode dissolution and energy inefficiency found in older technologies, making it the premier choice for a wide range of oxygen evolution applications.

The Core Components: A Synergistic Design

The electrode's performance is not the result of a single material, but the interaction between its substrate and a specialized coating.

The Titanium Substrate: The Stable Foundation

The base of the electrode is made from high-purity titanium, often formed into plates, meshes, or tubes. Titanium is chosen for its excellent mechanical strength and its ability to form a stable, non-conductive passive oxide layer, which provides a foundation of corrosion resistance.

The IrO₂-Ta₂O₅ Coating: The Catalytic Engine

The real work is done by the Mixed Metal Oxide (MMO) coating applied to the titanium. This coating consists primarily of Iridium Oxide (IrO₂) and Tantalum Oxide (Ta₂O₅).

Iridium Oxide is the primary electrocatalyst. It provides the active sites that dramatically lower the energy required to drive the oxygen evolution reaction.

Tantalum Oxide acts as a stabilizer. It enhances the coating's adhesion to the titanium substrate and improves its overall corrosion resistance, significantly extending the electrode's operational life.

Key Performance Characteristics Explained

These components give the electrode its defining operational advantages in environments where oxygen is produced electrolytically, such as those containing sulfates (SO₄²⁻).

High Electrocatalytic Activity

The electrode exhibits a low oxygen evolution overpotential (≤1.5V). This means it requires less excess voltage—and therefore less energy—to initiate and sustain oxygen production, leading to higher current efficiency and lower operational costs.

Superior Corrosion Resistance

The combination of the stable titanium substrate and the robust MMO coating makes the electrode extremely resistant to degradation in highly acidic or corrosive environments. This ensures a long service life and consistent performance.

High Current Density Operation

These anodes are engineered to handle very high current densities, often up to 15,000 A/m². This capability allows for high production rates and increased process throughput, making them ideal for industrial-scale applications like electrometallurgy and wastewater treatment.

Dimensional Stability and Purity

Unlike older graphite or lead anodes, the Iridium-Tantalum-Titanium electrode does not dissolve or change shape during operation. This dimensional stability keeps the distance between electrodes constant, ensuring stable cell voltage and preventing contamination of the electrolyte or final product.

Understanding the Trade-offs and Comparisons

No single electrode is perfect for every task. Understanding how the Iridium-Tantalum (Ir-Ta) anode compares to other common types is crucial for making an informed decision.

Ir-Ta vs. Ruthenium-based Anodes

This is a frequent point of confusion. Ruthenium-based anodes are optimized for chlorine evolution (e.g., in brine electrolysis). Iridium-based anodes like this one are specifically designed and superior for oxygen evolution. Using the wrong one results in poor efficiency and a drastically shortened lifespan.

Ir-Ta vs. Lead Dioxide (PbO₂) Anodes

Lead Dioxide is another common oxygen evolution anode. PbO₂ has a higher oxygen evolution potential (≥1.70V), giving it stronger oxidizing power for destroying highly refractory organic pollutants.

However, this comes at a cost. The Ir-Ta anode is significantly more energy-efficient, especially at the high current densities (>500A/m²) common in industrial processes.

The Reusability Factor

A significant economic advantage is the reusability of the titanium substrate. Once the catalytic MMO coating is depleted after its long service life, the electrode can be stripped and recoated, restoring it to full performance for a fraction of the cost of a new unit.

Making the Right Choice for Your Application

Your choice of anode must align directly with your process chemistry and economic goals.

- If your primary focus is energy efficiency and stable operation in most oxygen evolution processes: The Iridium-Tantalum electrode is the industry standard, offering the best balance of performance, lifespan, and energy consumption.

- If your primary focus is maximum oxidizing power for destroying specific, difficult pollutants: A Lead Dioxide (PbO₂) electrode might be necessary, but you must be prepared for higher energy costs.

- If your primary focus is generating chlorine from chloride solutions: You must use a Ruthenium-based anode, as an Iridium-Tantalum anode is not designed for this environment.

By understanding these fundamental characteristics, you can select the anode that delivers the most effective and economical performance for your specific goal.

Summary Table:

| Feature | Benefit |

|---|---|

| Low Overpotential (≤1.5V) | High energy efficiency and lower operating costs |

| Exceptional Corrosion Resistance | Long service life in acidic/corrosive environments |

| High Current Density (up to 15k A/m²) | High production rates and process throughput |

| Dimensional Stability | Stable cell voltage and no product contamination |

| Reusable Titanium Substrate | Cost-effective recoating option after coating depletion |

Ready to optimize your electrolysis process with the right anode?

KINTEK specializes in high-performance lab equipment and consumables, including advanced electrodes for industrial and research applications. Our expertise ensures you get the most efficient and durable solution for your specific oxygen evolution needs, from electrometallurgy to wastewater treatment.

Contact our experts today to discuss how our Iridium-Tantalum-Titanium electrodes can enhance your lab's efficiency and reduce operational costs.

Visual Guide

Related Products

- Iridium Dioxide IrO2 for Water Electrolysis

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- Which solvent is normally used in IR spectroscopy? Optimize Your Sample Prep for Clearer Results

- What are the 3 types of electrode? A Guide to Anode, Cathode, Active, and Inert Electrodes

- What is the difference between oxidizing and reducing environments? Key Insights for Chemical Reactions

- What are the application areas for the Ruthenium-Iridium-Titanium Chlorine Evolution Electrode? Essential for Efficient Chlorine Production

- How does concentration affect IR? Master Quantitative Analysis and Spectral Interpretation