The single greatest hazard of a press machine is catastrophic injury at the point of operation. These machines generate immense force in a concentrated area, creating a severe and immediate risk of crushing and amputation for any operator who is not adequately protected. Beyond this primary danger, press machines also present significant mechanical, electrical, and hydraulic hazards.

The inherent danger of a press machine lies in its core function: the delivery of massive force. True safety is never guaranteed by a machine's design alone; it is achieved through a multi-layered system of physical guards, fail-safe controls, and rigorous operational procedures.

The Primary Hazard: Mechanical Energy and Crushing

The fundamental danger of any press is the mechanical force it is designed to deliver. Understanding where and how this energy is released is the first step in mitigating risk.

Point of Operation

The point of operation is where the die or tool performs work on the material. This is, without question, the most dangerous area of the machine.

Any body part, typically hands or arms, caught in this zone during a cycle will be subjected to forces capable of causing immediate amputation or life-altering crushing injuries.

Moving Parts and Pinch Points

Beyond the primary tool, the machine's power train—including flywheels, gears, belts, and linkages—creates numerous pinch points.

These are areas where a moving part of the machine moves past a stationary part, creating a shearing or crushing hazard for clothing, hair, or limbs.

Ejected Parts or Material

A press cycle subjects the tooling (dies) and the workpiece to extreme stress. A fractured die or shattered workpiece can be ejected from the machine at high velocity.

These projectiles pose a significant impact hazard to the operator and anyone else in the vicinity.

Secondary Hazards: Beyond the Mechanical

While mechanical force is the most obvious risk, the systems that power and control the press introduce their own set of serious hazards.

Hydraulic and Pneumatic Systems

Hydraulic presses operate using fluid under extremely high pressure. A pinhole leak in a hose can eject a nearly invisible stream of fluid powerful enough to penetrate skin and cause a severe fluid injection injury, which is a medical emergency.

Sudden failure of pneumatic or hydraulic components can also lead to an uncontrolled and rapid release of stored energy, causing the press ram to drop unexpectedly.

Electrical Hazards

Press machines are powerful electrical devices. The primary risks are electrocution or severe shock from contact with damaged wiring, open control panels, or improperly grounded equipment.

Failure to de-energize the machine correctly before maintenance is a leading cause of electrical accidents.

Noise and Ergonomic Risks

The constant, high-decibel impact of many presses can lead to permanent hearing loss over time.

Furthermore, the repetitive motions required to load and unload a press can lead to musculoskeletal disorders (MSDs) affecting the back, shoulders, and arms.

Understanding Critical Failure Points

Trusting a single safety feature is a common and dangerous mistake. A robust safety system acknowledges that any individual component can fail or be bypassed.

Over-reliance on a Single Safety Feature

No single guard is foolproof. A light curtain can be misaligned, a two-hand control can be defeated by a single operator, and a physical barrier can be removed.

Effective safety relies on layers of protection, often called "redundancy," where multiple systems work together to protect the operator.

Inadequate Lockout/Tagout (LOTO)

The most severe press-related injuries often occur during maintenance, setup, or jam-clearing, not during normal production.

Failing to implement and enforce a strict Lockout/Tagout (LOTO) program—which ensures the machine is completely de-energized and cannot be started—is a critical safety failure.

Bypassing Safety Guards

Operators or maintenance personnel may be tempted to disable or bypass safety devices to speed up production or make a task easier.

This practice eliminates crucial layers of protection and dramatically increases the risk of a catastrophic accident. It must be strictly prohibited.

Implementing a Robust Press Safety Program

Your approach to safety must be comprehensive, addressing the machine, the operator, and your procedures.

- If your primary focus is operator protection: Your absolute priority must be effective point-of-operation guarding, such as fixed barrier guards, light curtains, or properly implemented two-hand controls.

- If your primary focus is maintenance safety: Mandate, audit, and enforce a zero-tolerance Lockout/Tagout (LOTO) program for any task that requires an employee to place any part of their body into a danger zone.

- If your primary focus is overall risk reduction: Implement a multi-layered system that combines engineering controls (guards), administrative controls (rigorous training, supervision), and appropriate Personal Protective Equipment (PPE).

A safe operation is the product of continuous vigilance, not a one-time setup.

Summary Table:

| Hazard Type | Primary Risk | Key Safety Focus |

|---|---|---|

| Mechanical | Crushing/Amputation at Point of Operation | Point-of-operation guarding (light curtains, two-hand controls) |

| Hydraulic/Pneumatic | High-Pressure Fluid Injection | Regular hose inspection, Lockout/Tagout (LOTO) procedures |

| Electrical | Electrocution from Live Components | Secure panels, proper grounding, strict LOTO enforcement |

| Ejection | Impact from Projectiles | Tooling inspection, use of barriers |

| Ergonomic | Musculoskeletal Disorders (MSDs) | Ergonomic workstation design, task rotation |

Ensure your press operations are safe and compliant. The risks of crushing, amputation, and hydraulic injection are severe, but they can be managed with the right equipment and protocols. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you identify the right safety solutions for your specific press machine application. Contact us today for a consultation and let us help you build a robust, multi-layered safety program to protect your team and your productivity.

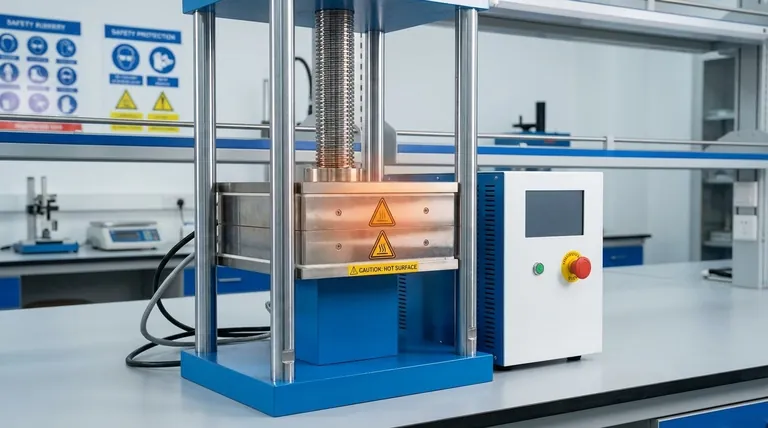

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation