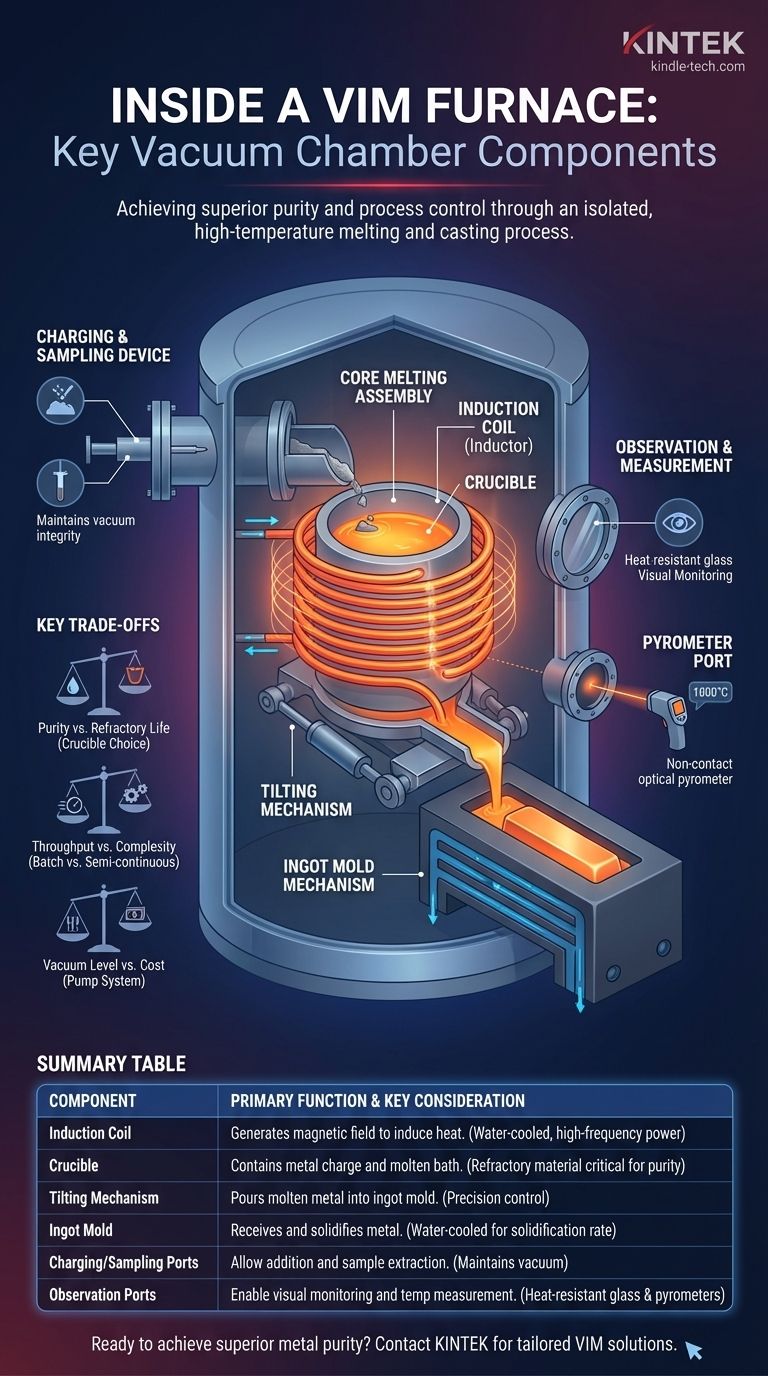

At its core, the vacuum chamber of a vacuum induction melting (VIM) furnace contains the complete melting and casting apparatus. The primary components inside this chamber are the induction coil, the refractory-lined crucible that holds the metal, a tilting mechanism for pouring, and an ingot mold mechanism to receive the molten metal. These are supplemented by ports and devices for charging, sampling, and observation.

The purpose of a VIM furnace is to execute the entire high-temperature melting and casting process within a tightly controlled vacuum. The components inside the chamber are designed for mechanical operation in this environment, while the critical support systems—vacuum pumps, power, and cooling—operate externally.

The Core Melting Assembly

The heart of the VIM furnace is the induction furnace itself, a self-contained unit designed to melt metal cleanly and efficiently.

The Induction Coil (Inductor)

The induction coil is the engine of the furnace. A high-frequency alternating current from an external power supply passes through this water-cooled copper coil.

This current generates a powerful and reversing magnetic field. This field induces strong electrical currents (eddy currents) within the metallic charge inside the crucible, rapidly generating heat and causing it to melt.

The Crucible

The crucible is the vessel that contains the metal charge and the subsequent molten bath. It sits inside the induction coil but is not in direct contact with it.

It must be made from a refractory material, a ceramic capable of withstanding extreme temperatures without melting or reacting with the molten alloy. The choice of refractory is critical to preventing contamination and ensuring the purity of the final product.

Manipulating the Melt and Casting the Ingot

Once the metal is molten, the furnace's internal mechanisms take over to handle the material and cast it into a solid form.

The Tilting Mechanism

The entire assembly of the coil and crucible is mounted on a tilting mechanism. This hydraulic or electro-mechanical system allows the operator to precisely tilt the furnace to pour the molten metal smoothly into the ingot mold.

The Ingot Mold Mechanism

Positioned to receive the molten metal is the ingot mold. This is where the liquid alloy solidifies into its final shape. These molds are often water-cooled to help control the solidification rate, which is crucial for achieving the desired metallurgical structure.

Interacting with the Process Under Vacuum

To be a functional tool, the furnace requires ways for operators to observe, control, and interact with the melt without breaking the vacuum.

Charging and Sampling Devices

Specialized ports and mechanisms are built into the furnace shell. A charging device allows raw materials to be added to the crucible while the chamber is under vacuum, often using a system of airlocks.

Similarly, a sampling device allows a small amount of the molten metal to be extracted for chemical analysis, ensuring the batch meets specifications before pouring.

Observation and Measurement Ports

The furnace shell includes viewports made of specialized, heat-resistant glass, allowing operators to visually monitor the melting process.

Temperature is typically measured using non-contact optical pyrometers aimed at the molten bath through another dedicated port, providing critical data for process control.

Understanding the Trade-offs

The design and operation of a VIM furnace involve balancing competing priorities. Understanding these trade-offs is key to its effective use.

Purity vs. Refractory Life

The crucible is essential but also a primary source of potential contamination. While highly inert refractories exist, they can be more expensive or have a shorter service life. The choice is always a balance between the required alloy purity and the operational cost.

Throughput vs. Complexity

Furnaces can be intermittent (batch) or semi-continuous. An intermittent furnace is simpler, but the entire chamber must be brought to atmospheric pressure to remove the ingot and add a new charge.

A semi-continuous design uses vacuum locks for charging and mold removal, dramatically increasing throughput but adding significant mechanical complexity and cost to the system.

Vacuum Level vs. Cost

Achieving a higher vacuum (lower pressure) allows for better removal of dissolved gases and prevents reactions with trace elements. However, reaching and maintaining a very high vacuum requires a more powerful, complex, and expensive vacuum pump system. The required vacuum level is dictated by the specific alloys being processed.

Making the Right Choice for Your Goal

Each component inside the chamber serves a distinct purpose, and their integration defines the furnace's capability.

- If your primary focus is maximum purity: Your critical components are the high-integrity vacuum system and the selection of the most non-reactive crucible material for your specific alloy.

- If your primary focus is high throughput: A semi-continuous design with reliable, automated mechanisms for charging and ingot removal is essential.

- If your primary focus is melting reactive alloys: A powerful vacuum system capable of reaching low pressures is non-negotiable, coupled with precise temperature control and observation systems.

Ultimately, every component works in concert to transform solid metal into a highly pure, precisely controlled liquid within an isolated vacuum environment.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Induction Coil | Generates magnetic field to induce heat in the metal | Water-cooled to handle high-frequency power |

| Crucible | Contains the metal charge and molten bath | Refractory material choice is critical for purity |

| Tilting Mechanism | Pours molten metal into the ingot mold | Requires precision hydraulic/electro-mechanical control |

| Ingot Mold | Receives and solidifies the molten metal | Often water-cooled to control solidification rate |

| Charging/Sampling Ports | Allow material addition and sample extraction under vacuum | Maintains vacuum integrity during operation |

| Observation Ports | Enable visual monitoring and temperature measurement | Uses specialized heat-resistant glass and pyrometers |

Ready to achieve superior metal purity and process control?

At KINTEK, we specialize in providing high-performance lab equipment, including vacuum induction melting furnaces tailored to your specific needs. Whether your focus is on maximizing purity for reactive alloys or increasing throughput with semi-continuous designs, our expertise ensures you get the right solution.

Contact us today to discuss how our VIM furnaces and consumables can enhance your laboratory's capabilities and deliver the precise results you demand.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- Is induction heating more efficient than resistance? Unlock up to 50% greater energy savings.

- Does induction heating work on titanium? Mastering the Process for Aerospace & Medical Alloys

- What is induction furnaces based on the heating effect of? Unlock Faster, Cleaner Metal Melting

- What is the difference between induction heating and electric heating? Master Direct vs. Indirect Heat Generation

- What is the benefit of induction furnace? Achieve Purity, Precision, and Efficiency in Metal Melting

- What are the applications of vertical core induction type furnace? Unlock Precision High-Temp Processing

- What material is arc melting? A Guide to High-Purity Metal & Alloy Fabrication

- What are induction furnaces made of? Key Components for Efficient Metal Melting