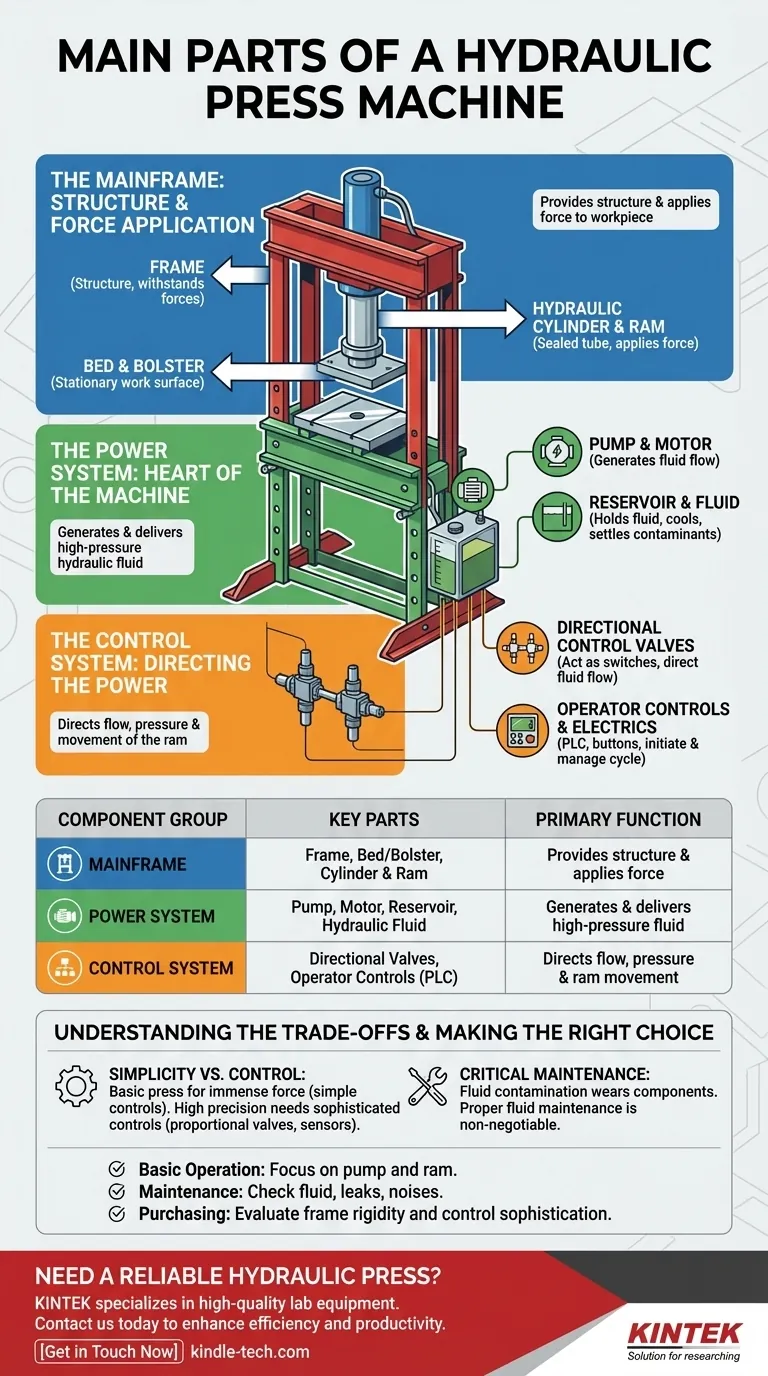

In essence, a hydraulic press operates using three main component groups: the mainframe that provides the structure, a power system that generates hydraulic pressure, and a control system that directs the application of that pressure. These elements work in concert to convert hydraulic fluid pressure into a powerful mechanical force for shaping, pressing, or assembling materials.

A hydraulic press is best understood not as a single machine, but as an integrated system. A structural frame holds the workpiece, a power unit creates high-pressure fluid, and a control system precisely directs that force to perform work.

The Mainframe: Structure and Force Application

The mainframe consists of the large, heavy components that provide the machine's physical strength and apply the force to the workpiece.

The Frame

The frame is the primary structure of the press. It is engineered to withstand the immense forces generated during operation without flexing or failing, ensuring accuracy and safety.

The Bed and Bolster

The bed is the stationary work surface where the lower die or workpiece is placed. It is often fitted with a bolster plate, a thick, removable plate that protects the bed and provides a mounting surface for tooling.

The Hydraulic Cylinder and Ram

The hydraulic cylinder is a sealed tube containing a piston. The ram is the solid cylindrical shaft connected to this piston that extends out from the cylinder to press the workpiece. When high-pressure fluid is pumped into the cylinder, it pushes the piston and ram downwards with tremendous force.

The Power System: The Heart of the Machine

The power system, often a self-contained assembly called a Hydraulic Power Unit (HPU), is responsible for creating and delivering the high-pressure fluid that drives the ram.

The Pump and Motor

An electric motor drives a hydraulic pump. The pump's job is not to create pressure itself, but to create a flow of hydraulic fluid. Pressure is built when this flow meets resistance, such as the workpiece in the press.

The Reservoir and Fluid

The reservoir is a tank that holds the supply of hydraulic fluid (typically a specialized oil). It also helps to cool the fluid and allow contaminants to settle out before the fluid is drawn back into the pump.

The Control System: Directing the Power

The control system is the brain of the press. It manages the flow, pressure, and direction of the hydraulic fluid to control the ram's movement, speed, and force.

Directional Control Valves

Valves are the most critical part of the control system. They act like switches and gates, opening and closing to direct the flow of hydraulic fluid to extend or retract the cylinder, or to hold it in a specific position.

Operator Controls and Electrics

This includes the buttons, touch screens (PLCs), and electrical logic that allow an operator to initiate and manage the press cycle. Modern controls allow for precise regulation of ram speed, position, and applied tonnage.

Understanding the Trade-offs: Simplicity vs. Control

The core components of a hydraulic press are mechanically simple, which is a key advantage for reliability and power. However, this simplicity presents a fundamental trade-off.

A basic press with simple controls offers immense force but may lack the fine control needed for delicate or complex operations. Achieving high precision requires a more sophisticated and expensive control system with proportional valves and advanced sensors.

Furthermore, the hydraulic fluid itself is a critical component that demands attention. Contamination or degradation of the fluid can rapidly wear out the pump and valves, leading to a loss of performance and eventual failure. Proper fluid maintenance is non-negotiable for machine longevity.

Making the Right Choice for Your Goal

Understanding these systems allows you to focus on the aspects most relevant to your work.

- If your primary focus is basic operation: Concentrate on how the pump sends fluid to the cylinder, causing the ram to extend and apply force.

- If your primary focus is maintenance: Pay close attention to the hydraulic fluid's condition, check for leaks around cylinder seals, and listen for unusual noises from the pump.

- If your primary focus is purchasing a press: Evaluate the frame's rigidity for durability and the control system's sophistication for precision and repeatability.

By understanding how these core systems interrelate, you can effectively operate, maintain, or evaluate any hydraulic press.

Summary Table:

| Component Group | Key Parts | Primary Function |

|---|---|---|

| Mainframe | Frame, Bed/Bolster, Cylinder & Ram | Provides structure and applies force to the workpiece |

| Power System | Pump, Motor, Reservoir, Hydraulic Fluid | Generates and delivers high-pressure hydraulic fluid |

| Control System | Directional Valves, Operator Controls (PLC) | Directs the flow, pressure, and movement of the ram |

Need a Reliable Hydraulic Press for Your Lab or Production Line?

Understanding the components is the first step. Selecting the right press for your specific application—whether for material testing, sample preparation, or industrial forming—is crucial for achieving accurate and repeatable results.

KINTEK specializes in high-quality lab equipment, including hydraulic presses designed for durability, precision, and ease of use. Our experts can help you choose a press with the right frame strength, power system, and control sophistication for your needs.

Contact us today to discuss your requirements and discover how a KINTEK hydraulic press can enhance your efficiency and productivity.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why use a laboratory hydraulic press for sulfide batteries? Achieve 445 MPa for Optimal Ionic Conductivity

- What key indicators does a laboratory pressure testing machine measure? Essential T91 Alloy Steel Weld Testing

- How is a laboratory hydraulic press utilized in the preparation of samples during the solvent precipitation recovery of polyamides? Achieve Precise Densification

- How much sample required for powder XRD analysis? Optimize Your Material Analysis

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- What is an example of a hydraulic system in industry? The Power of Hydraulic Presses Explained

- What are the 3 basic parts needed for a hydraulic press? Build a Powerful Machine from the Core Components

- What is the purpose of using a laboratory hydraulic press for powder compaction? Achieve Precise Pellet Densification